About a week back I shared a blog post about replacing a printing head/nozzle, believing that issue was resolved. However, after running a few prints, I noticed that the current prints weren’t as strong as expected, which raised some concerns.

Initially, I checked the usual suspects: printing temperature, cooling, and the nozzle—now switched to an iron nozzle from the brass one. However, adjusting these factors didn’t resolve the issue. Comparing the new prints with those produced by the original head revealed numerous printing errors.

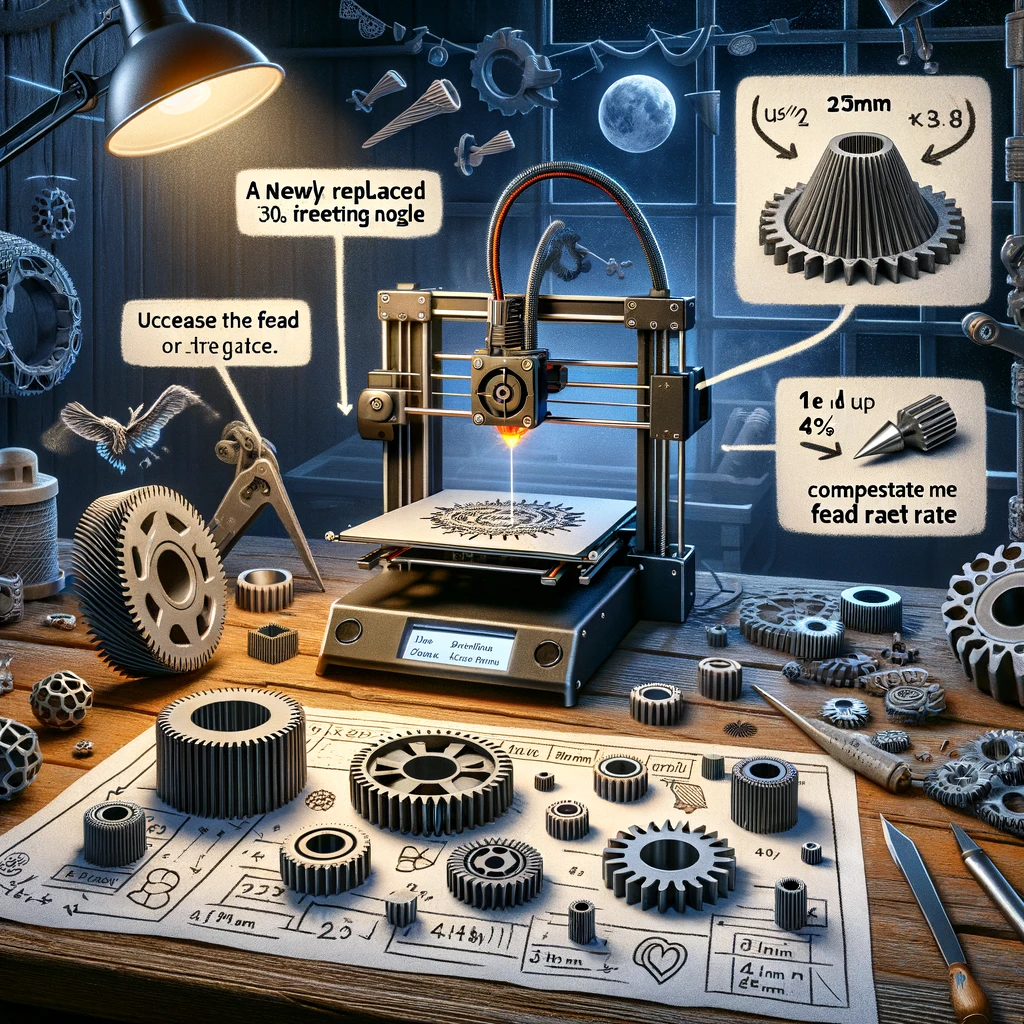

After some contemplation, I realized the issue might be related to the filament feed. A comparison of the feeding gear sizes confirmed my suspicions. The original gear had a diameter of 11mm, whereas the new one was only 8mm. Despite the unchanged rotation speed, this size difference significantly affected the feed rate.

A quick calculation of the circumferences indicated that the feed needed to be increased by 40% to match the original specifications. Adjusting the feed rate to 140% solved the problem, resulting in excellent print quality.

For now, I plan to adjust the gcode to reflect this change, but I’m hesitant to alter the current setup immediately. The world of 3D printing continues to surprise me with its complexities—there’s always something new to learn. 🙂