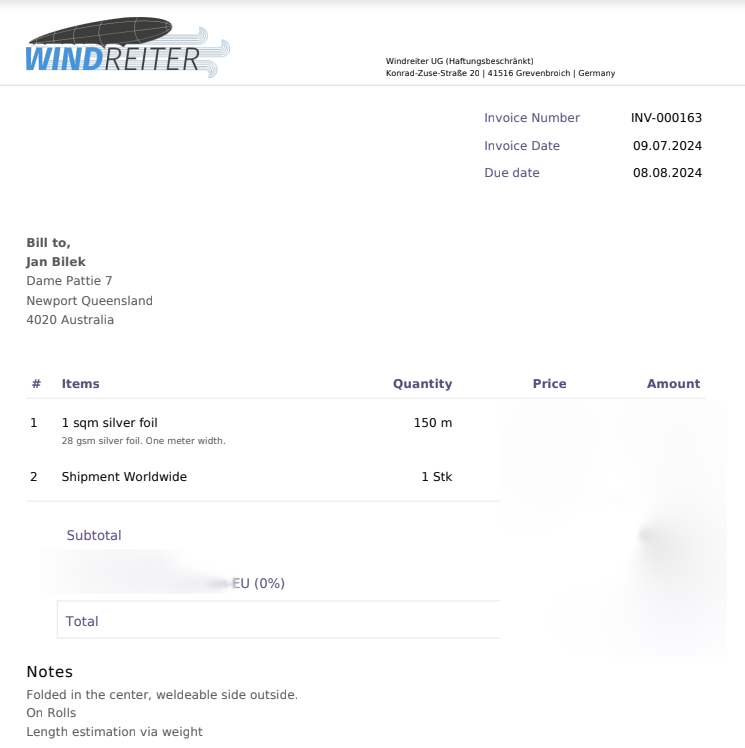

Things were bit quiet around lately, but we are actually making some good progress. The most important things first – the Windreiter guys (Andreas) agreed to provide us with huge amount of their Tritax blimp material, also giving us very friendly discount.

(Apparently they strongly discourage people from buying the foil directly from them as it is horrible work to re-roll precisely and most people then fail welding envelopes and then are pissed – so don’t do this!)

It took DHL couple weeks, but all arrived well and in a good shape.

Having material in our hands we immediately started with preps on few jigs and also to retest our welding technique. First part was to develop a a ring which would allow gimball trusses to pass through the envelope. It took a little to get that going with OpenSCAD.

use <ShortCuts.scad>

r1 = 20.5;

r2 = 35;

ribs = 16;

t1 = 2; //ribs thickness

t2 = 2; //slab thickness

t3 = 1.5; //tube thickness

length = 50;

module tube_inner() {

Ry(90)

cylinder(2, r2, r2, $fn = 100);

for(w=[0:360/ribs:359])

Rx(w)

linear_extrude(height = 2, v = [0, 0, 1], center = true, convexity = 10, slices = 20, scale = 1.0, $fn = 16)

polygon( points=[[0,r1],[t1+3,r1],[t1,r2-0.1],[0,r2-0.1]] );

Ry(90)

cylinder(length, r1, r1-1, $fn = 100);

}

module outer_tube() {

D() {

tube_inner();

Tx(-.1)

Ry(90)

cylinder(length+2, r1-t3, r1-1-t3, $fn = 100);

}

}

module inner_tube() {

D() {

Ry(90)

union(){

cylinder(2, r2, r2, $fn = 100);

cylinder(length, r1-t3, r1-1-t3, $fn = 100);

}

Tx(-.1)

Ry(90)

cylinder(length+2, r1-t3*2, r1-1-t3*2, $fn = 100);

}}

outer_tube();

inner_tube();

It worked out nicely:

Printing itself is now tuned to precision so those came out lovely as well.

Important part was to check on how will those jigs go though the envelope into inner sleeve.

As you can see, there was some trial and error process in place. Clearly using super-glue wasn’t good enough, but resenting back to Selley’s contact glue worked out well at the end. At the end I also did a test on stressing the seal and it looks like all envelope forces are distributed well and seal seems to be air-tight.

Next time we’ll need to test the welding and check how much stress these welds can take so we have some baseline value on expected envelope pressurisation.

One thought on “Envelope development update I”