In continuation of our envelope development effort – there are plenty new things happening these days.

First thing first, there is a mass production of the envelope valves and beam sleeves. Actually there are 20 of those needed, where each set takes bit over 5 hrs to print. Those are also coming in two colours – green and red, using the aircraft (or boating) code for side identification. 2 of those were left as blue ones as intended for generic filling / venting valves purpose.

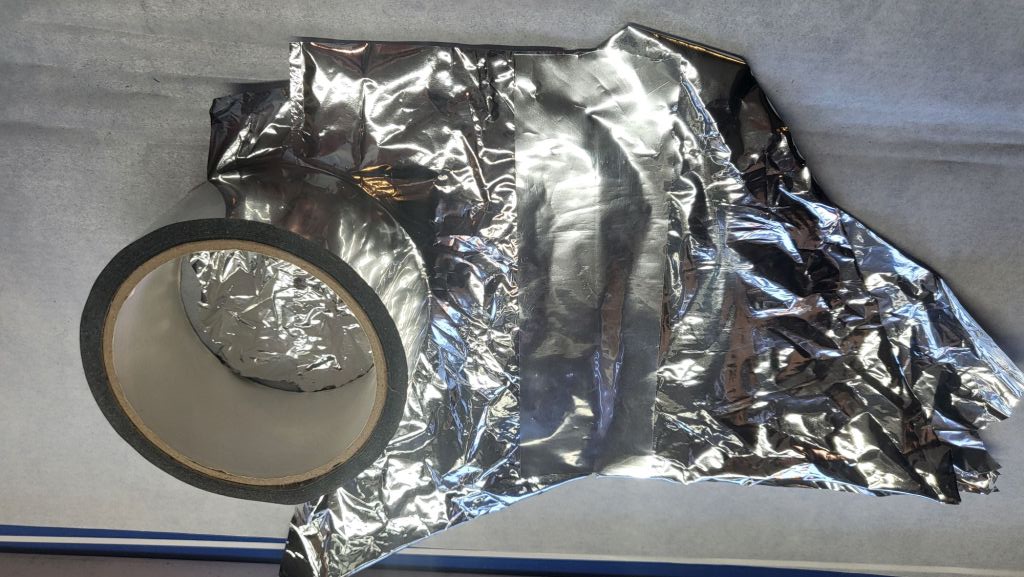

Second in line was to test our ability to fix existing envelope when having a rupture and also to test if we can use the tape to seal “the vedge” part. All the tests shown that both tapes (Mylar one and common industrial tape) can withstand much more than what’s needed.

The final test was to get some guiding values on the envelope pressurisation. For that we’ve extended our tiny Arduino project to record max pressure values for us and used their “Plotter” screen to visualise the output from the Serial port.

#include <Q2HX711.h>

#include <AverageValue.h>

const byte MPS_OUT_pin = 21; // OUT data pin

const byte MPS_SCK_pin = 22; // clock data pin

int avg_size = 10; // #pts to average over

long minVal = 100000;

long maxVal = 0;

Q2HX711 MPS20N0040D(MPS_OUT_pin, MPS_SCK_pin); // start comm with the HX710B

AverageValue<long> ave(avg_size);

void setup() {

Serial.begin(9600); // start the serial port

}

void loop() {

long measurement = MPS20N0040D.read()/ 256.0;

ave.push(measurement);

Serial.print(ave.average());

if (measurement < minVal)

minVal = measurement;

if (measurement > maxVal)

maxVal = measurement;

Serial.print(","); //seperator

Serial.print(maxVal);

Serial.print(","); //seperator

Serial.println(minVal);

}

Then we had quite a fun throughout several attempts to burst the envelope, while measuring its internal pressure. All of those are quite interesting.

Second try by Seb.

Third one – the final one, where Seb needed to use cycling pump! Don’t forget to get a sound pretty loud as it comes with cool sound effects! 😀

It is probably not too obvious on that video, but measured values were 32768 as the base-line and 49151 as the maximum. What are these values? No idea. What was clear is that when around 35000 the envelope was seriously hard. Whatever it means is that we are now quite confident that we can do pretty strong weld and also having some idea on pressure values to test our final envelope!

no to mě poser

LikeLike