In continuation of our work on envelope fixes, we repeated all the steps from last weekend with the starboard “green” envelope.

Knowing what we are up to, all job went much smoother this time. Inflated envelope seemed to be holding pressure in an acceptable manner.

After making significant progress with our initial milestones, our focus shifted to one last problematic component: the central gondola tube. This particular tube had suffered multiple fractures during previous test runs.

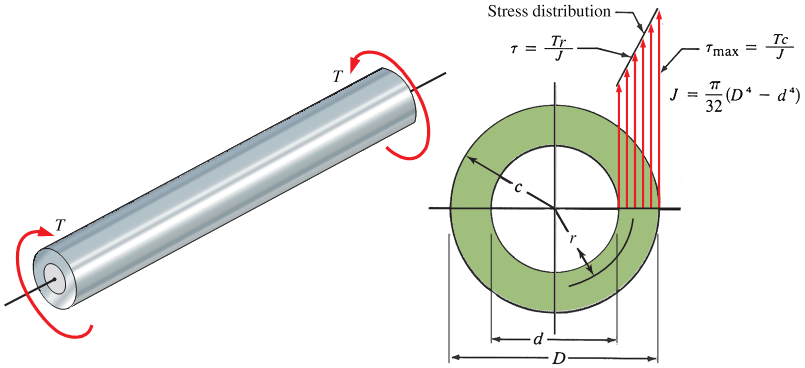

The failures were traced to excessive torsional forces acting on the tube. As the central gondola tube connects directly to the main traverse tubes (each 4 meters long and spaced 2 meters apart through the envelopes), it experienced substantial torsional loading from these points of attachment.

The diagram above illustrates the torsional stress distribution on a cylindrical element. The twisting action creates uneven shear stresses, which the initial central tube design wasn’t adequately prepared to withstand. In hindsight, we’re fortunate that the damage was confined to this tube, preventing a more systemic failure that could have propagated through the entire structure.

After discussing this with Serge, we decided on an alternative solution, which is depicted below.

The new design involves a split aluminum tube at the center, with an additional overlapping section designed to transfer all loads except torsional forces. The aluminum tube is shielded by a rubber hose, which is clamped at both ends using hose clamps. This rubber overlay allows for some controlled torsion flexibility, effectively acting as a damper to reduce stress concentrations. The intent behind this assembly is to isolate and minimize torsional forces on the main central tube, while still allowing the structure to behave elastically and return to its original state post-deformation.

This redesign should improve the resilience of the central tube, reducing the risk of fracture during future test flights and ensuring the gondola’s stability under dynamic conditions.

Obviously replacing super-light CF tube with Aluminum one came with a cost. Weighing revealed that gondola structure is now ~700g heavier. With the excess of 10kg we measured last time it shouldn’t be a big deal and I hope that this investment will pay off.

And that’s it for last weekend! Stay tuned as we are planning all motors test next week!

no to mě poser

LikeLike