FYI Original quick debrief report here.

It started quietly on a Friday. I had taken the day off to give our project, the space it needed to finally become airborne. Over the past four to five years, what began as a spark of curiosity turned into a deep obsession (Sebi likes saying that to all the peoples) an attempt to prove that airships, especially hydrogen-powered ones, still have a future. We were now about to put that to the test.

The Calm Before the Flight

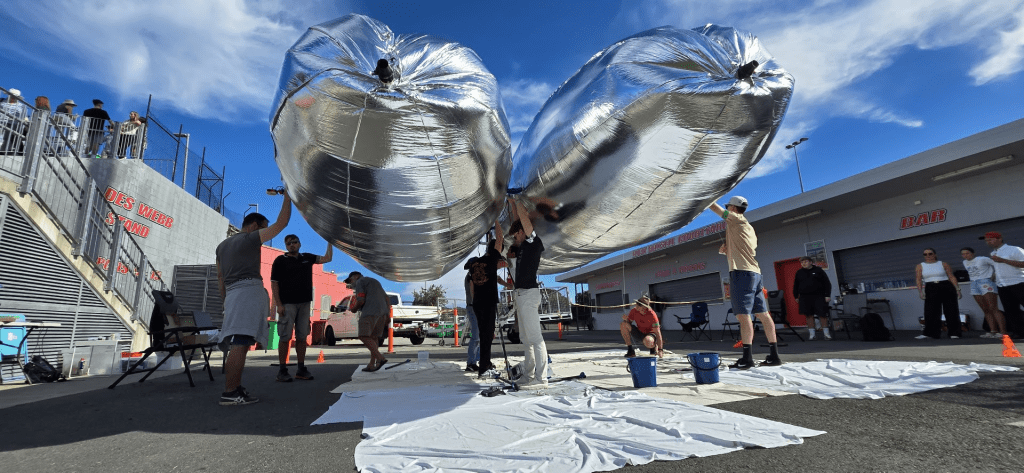

The prep days—Friday and Saturday—were productive in that satisfying way that comes when every cable is labeled, every motor is verified, and every part feels like it’s clicking into place. Sebi, had spent hours rewriting and testing the control logic on the Arduino, connecting everything from RC inputs to vectored thrusters and solenoids. We had one unresolved issue with a noisy EDF intake, which in hindsight should have been replaced—but overall, we went to bed on Saturday night feeling ready, in that “ok-ish” sort of way engineers know well.

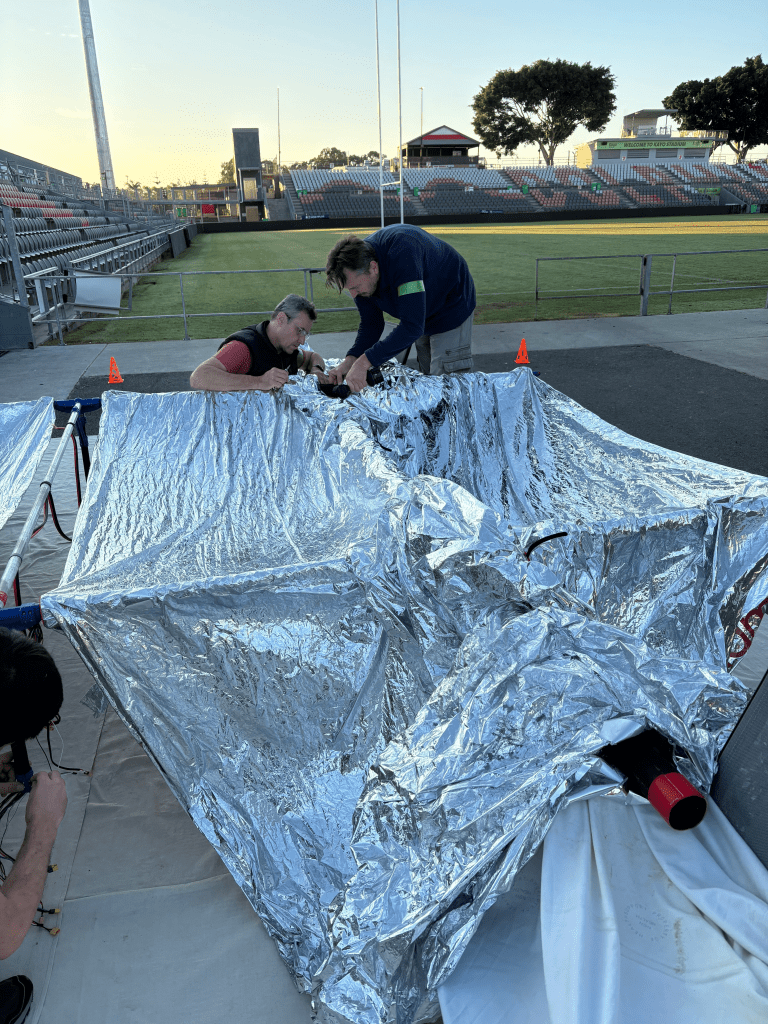

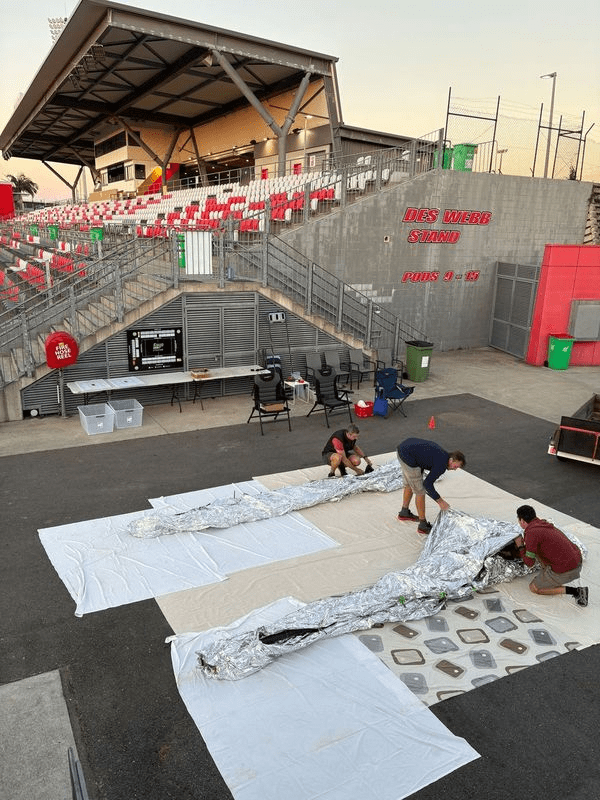

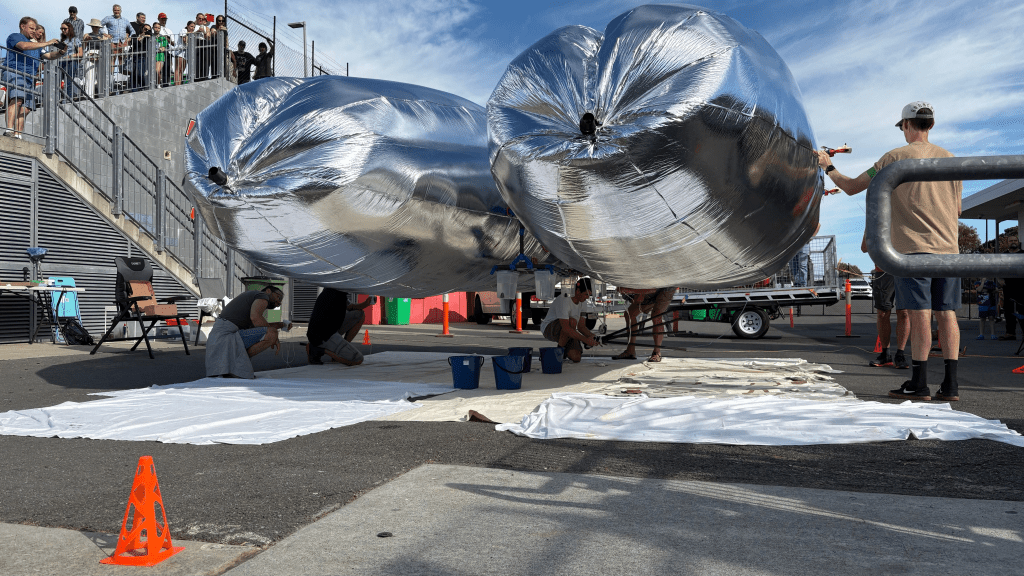

A new valve for splitting the Hydrogen evenly between both envelopes has been designed, printed and wrapped with Alumin.

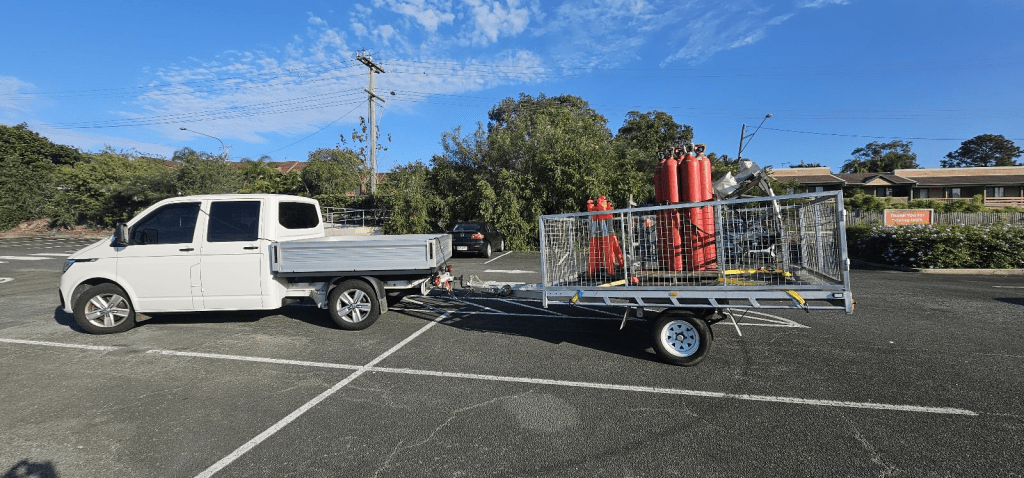

Hydrogen arrived on Thursday before the demo, thanks to CoreGas. Five pristine H2 cylinders and a pallet delivered to Vilem’s workplace, complete with a forklift cameo and some very photogenic logistics.

Wodek Jakubik and Mayur Kora went above and beyond—not just delivering gas, but sharing safety protocols and technical suggestions that we took seriously and followed. We couldn’t have asked for better partners.

Game Day at Kayo Stadium

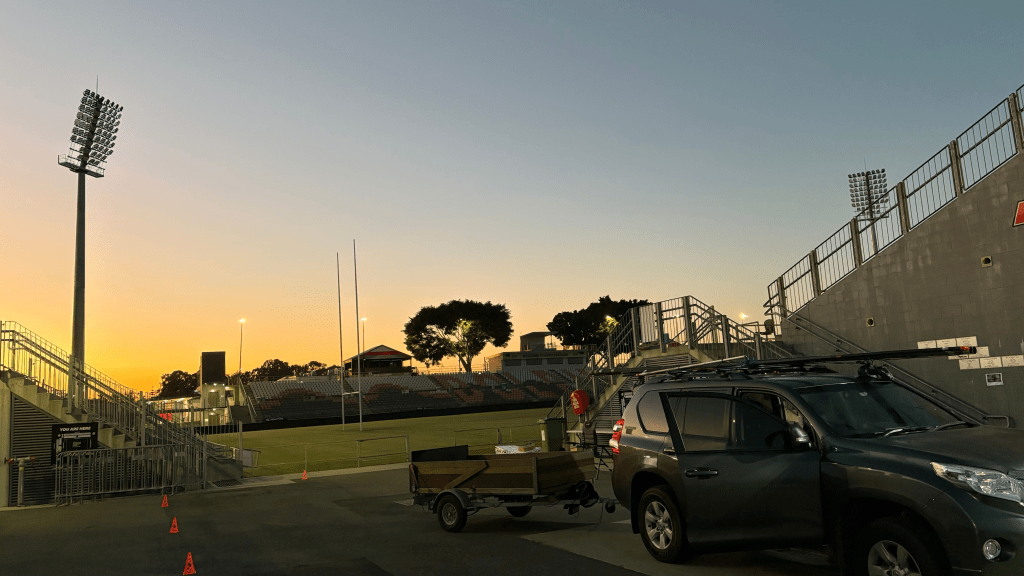

The sun rose over Kayo Stadium in Redcliffe with just the right kind of sky—calm, light clouds, 5-7 km/h winds. I saw the vanning moon and Venus hanging over the north tribune at 5:00 AM and knew the day was starting just right.

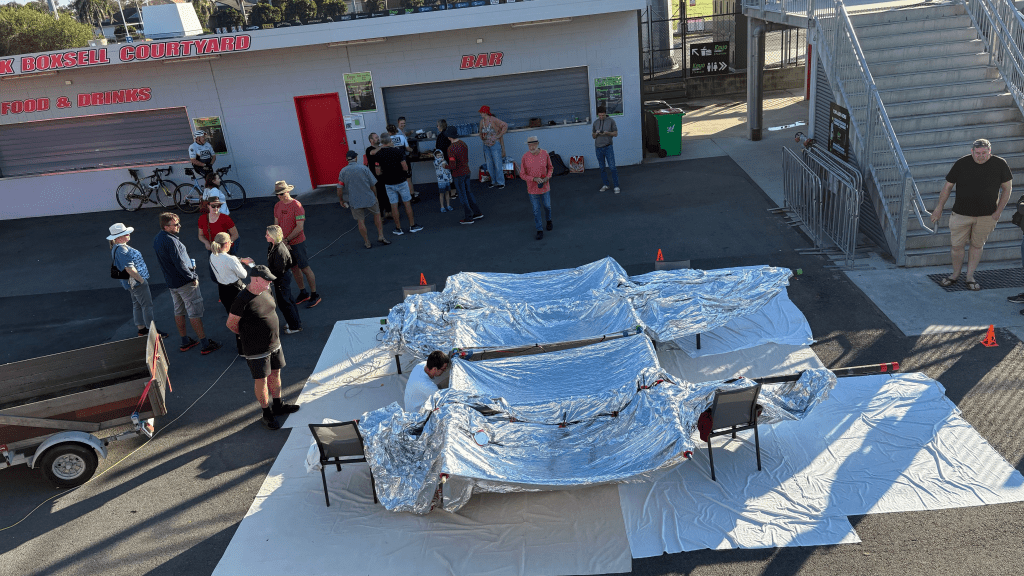

Early birds Mick Cullen and I started unloading gear well before sunrise. By 7:00 AM, the assembly area was alive. Sheets laid out, ducts inserted, envelopes unfurled.

Kristian and Lumir mounted the hydrogen fuel cell platform at the heart of the gondola, lighting up LEDs powered entirely by our H2 system—a small, glowing promise of flight.

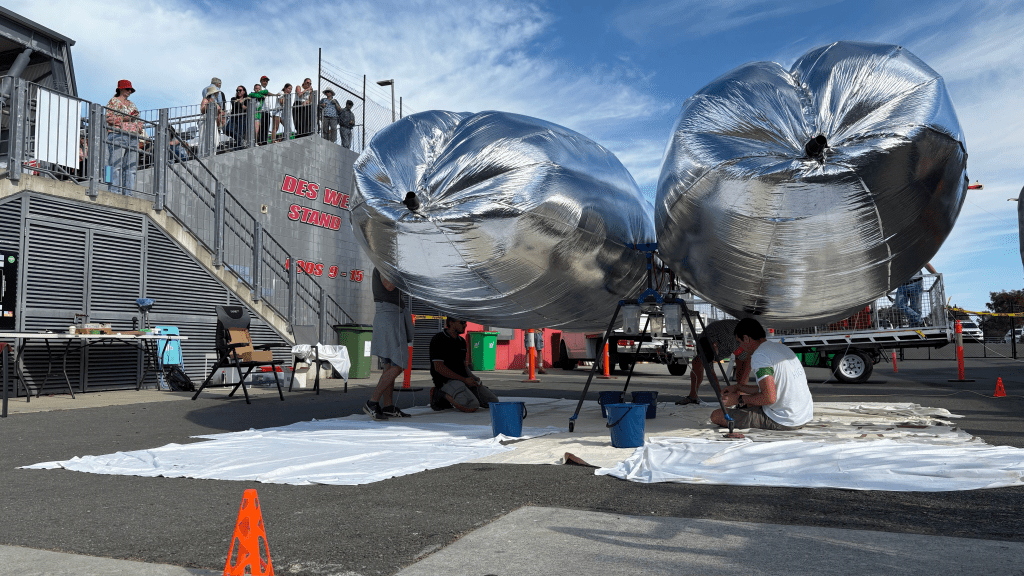

The RED security team—Rob, Damien, and Channon—kept the growing crowd in order while our media team (Silver team) began setting up drones, GoPros, and timelapse rigs. Around 8:30, everything came together. We paused, breathed, and ran the safety briefing from Chapter 8 of our Flight Plan.

Guests signed the airship envelope one by one. Some wrote names. Others just smiled. It was touching.

Greg Williams arrived. The airship was christened after him—a friend and quiet supporter of this project (and of our lives) for over a decade. And Serge Testa, our own local legend, stood by ready to operate the hydrogen. These two men represent roots and legacy, and I wanted them there for this historic moment.

<Image Greg & Jan TBA>

Lift-Off and Learning

Hydrogen inflation began just after 9:00 AM. First one bottle, then the next. We soon noticed that the port envelope was inflating faster—a sign of imbalance.

As we prepared to mount the ballast tanks, the envelope pulled upward, and our team wrestled with buckets of water and tethered tanks, all while the gondola floated between them. This was uncharted territory, but it worked.

The airship lifted perfectly level, buoyed by theory, water, and hydrogen.

That’s when I made the call to mount the landing suspension. It felt like the right decision at the time. The wheels would allow a landing. But I now think it introduced structural stress that played a role in what happened next.

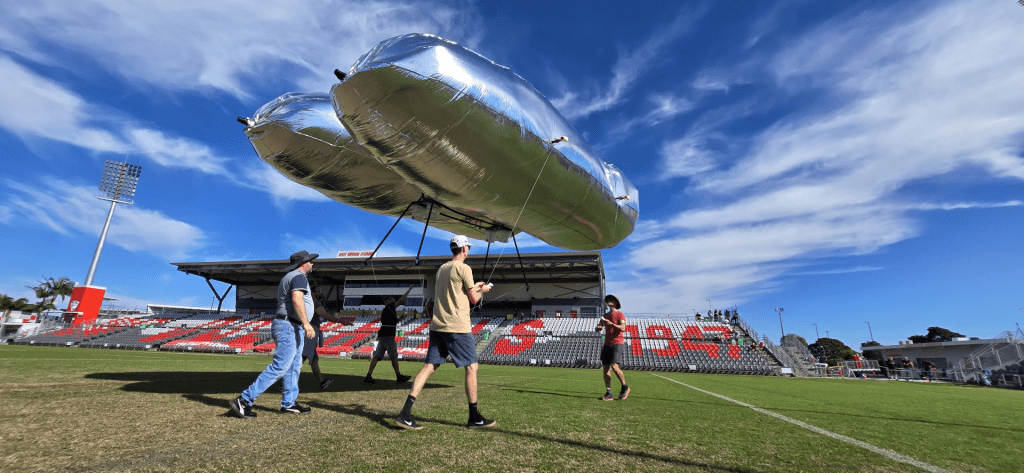

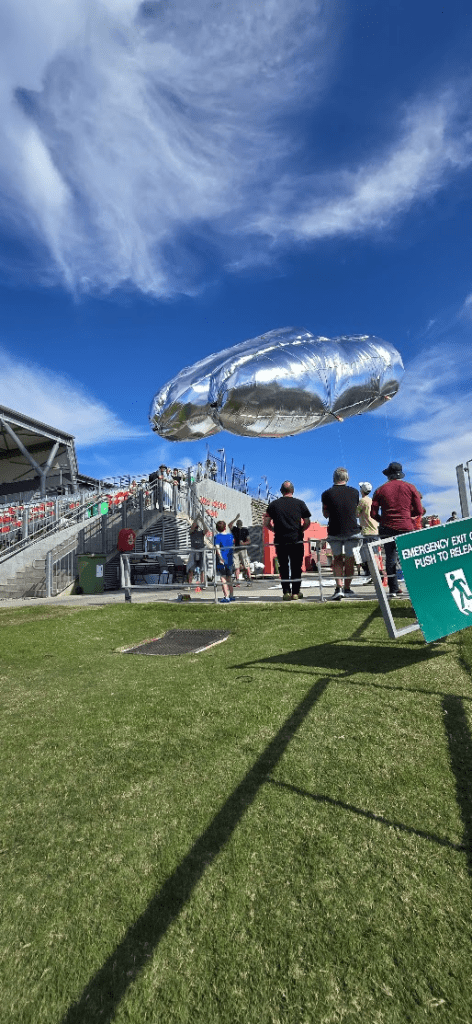

Around 9:30 AM, we moved the airship to the field. Sebi brought it up to 5 meters. A gust hit just as he engaged forward thrust. Despite great control using vectored gimbals, the deflating port envelope, now out of ballast, caused concern.

I ordered it down. We returned for hydrogen and water refill.

During that process, while refilling rear ballast tanks, someone tripped on a wheel. The gondola, already strained, sheared away from the main structure. The back separated, then the front. I raised my hand – “Catastrophic malfunction”. That should have been the end.

But in the moment, we allowed one last promenade of the freed envelopes around the field. It was meant to be symbolic, but the tethers couldn’t handle the full buoyancy. One by one, they gave way.

The Runaway Airship

And just like that, the airship was gone.

It floated upward, steady and slow. There was a surreal quiet. Suggestions came—”Fly a drone into it,” someone said. But the risk of where it would fall was too great. Instead, we watched. We hoped the wind would take it out to sea.

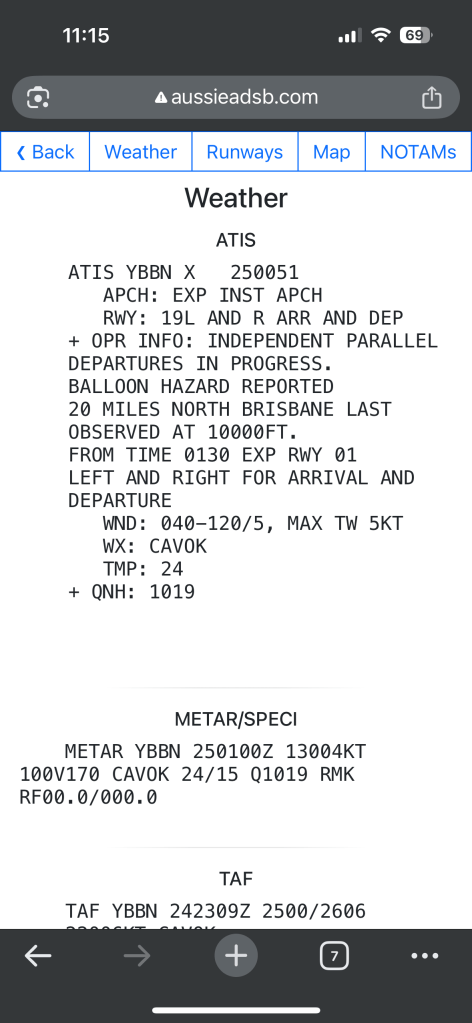

Mick called Brisbane ATC to report a 5–10 kg silver object drifting eastward. They acknowledged it, appreciated the info, and told us not to worry.

Guests mingled, took photos, asked questions. I told many that our odds were 50:50—and most smiled, knowing this was never just about success. It was about the courage to try.

A Fishy Recovery

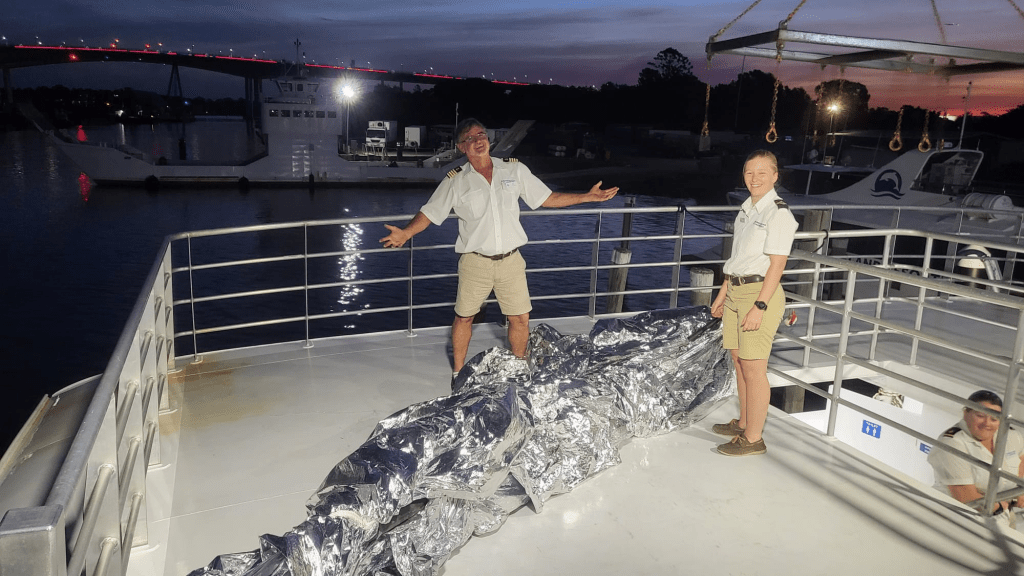

At a low-key afterparty in Scarborough, the call came in. Kristian had seen a Facebook post: “Things ya find in the bay?” There it was—our airship, one envelope deflated, bobbing on the water.

The Reef Cat ferry had found it. After a bit of detective work, we connected with their crew and raced to the docks. The captain—delighted by his silver catch—posed for a photo, called it a UFO, and joked about tracking down Greg Williams in WA. They helped us unload the airship, shared GPS coordinates, and even offered photos and videos of the rescue.

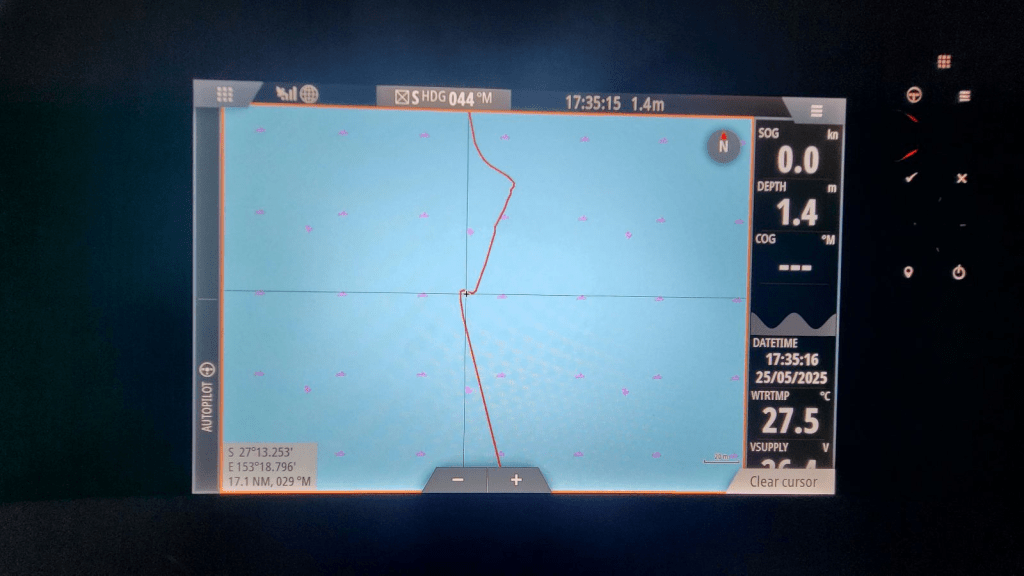

Turns out, our airship had floated 21.4 kilometres over 3–4 hours. From Kayo Stadium to Moreton Bay—an unplanned, poetic flight.

What We Take With Us

Was this demo perfect? Not by a long shot. But did we achieve something remarkable? Absolutely.

We validated:

- A hydrogen-powered, electric airship system

- A working ballast control and hover setup

- A biconvex design never flown before

- A centralized propulsion concept combining ducting and vectored thrust

- The potential to use hydrogen for both lift and power

We also learned:

- Follow the test plan, especially in critical moments

- Don’t add new features at the last minute

- Build envelopes to industrial standards

- Never underestimate the value of a focused, protected workspace

- Test software changes in full, dry-run conditions

But beyond all that, we brought something bold into the world—and it flew.

Thank you to CoreGas, Dolphins NRL, our brilliant team, our families—especially Veronika for holding this all together, and Sebi for flying our dream into the sky.

And thank you to Serge and Greg for the wisdom, history, and friendship that lifted us higher than hydrogen ever could.

This was Phase I. And now, we begin what comes next.

ty vole, to je prdel, jste slavný

LikeLike

Amazing video and excellent use of technology.

LikeLike