Through the past months following two cool gears ideas landed in our mailbox. Enjoy!

Category: Uncategorized

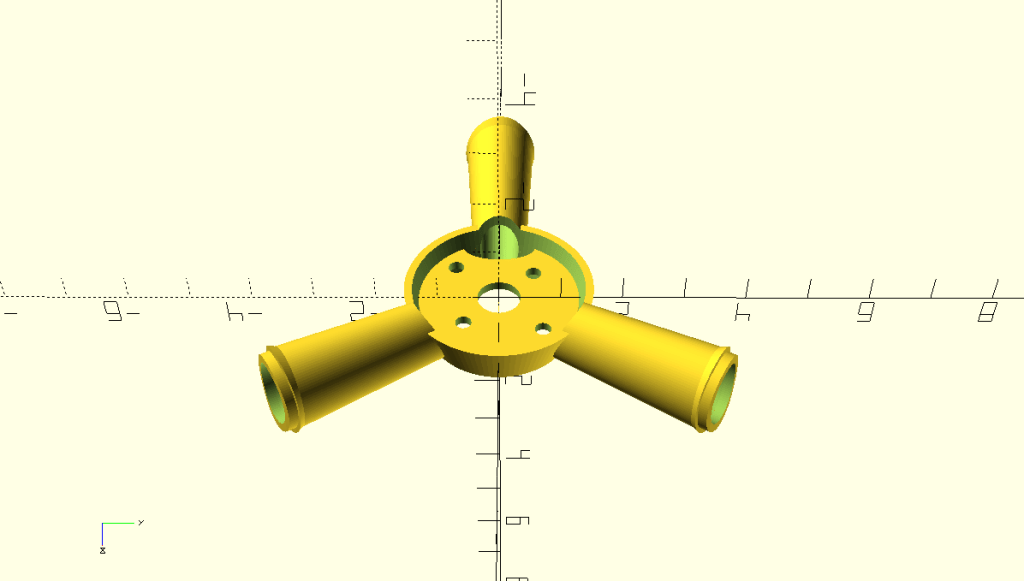

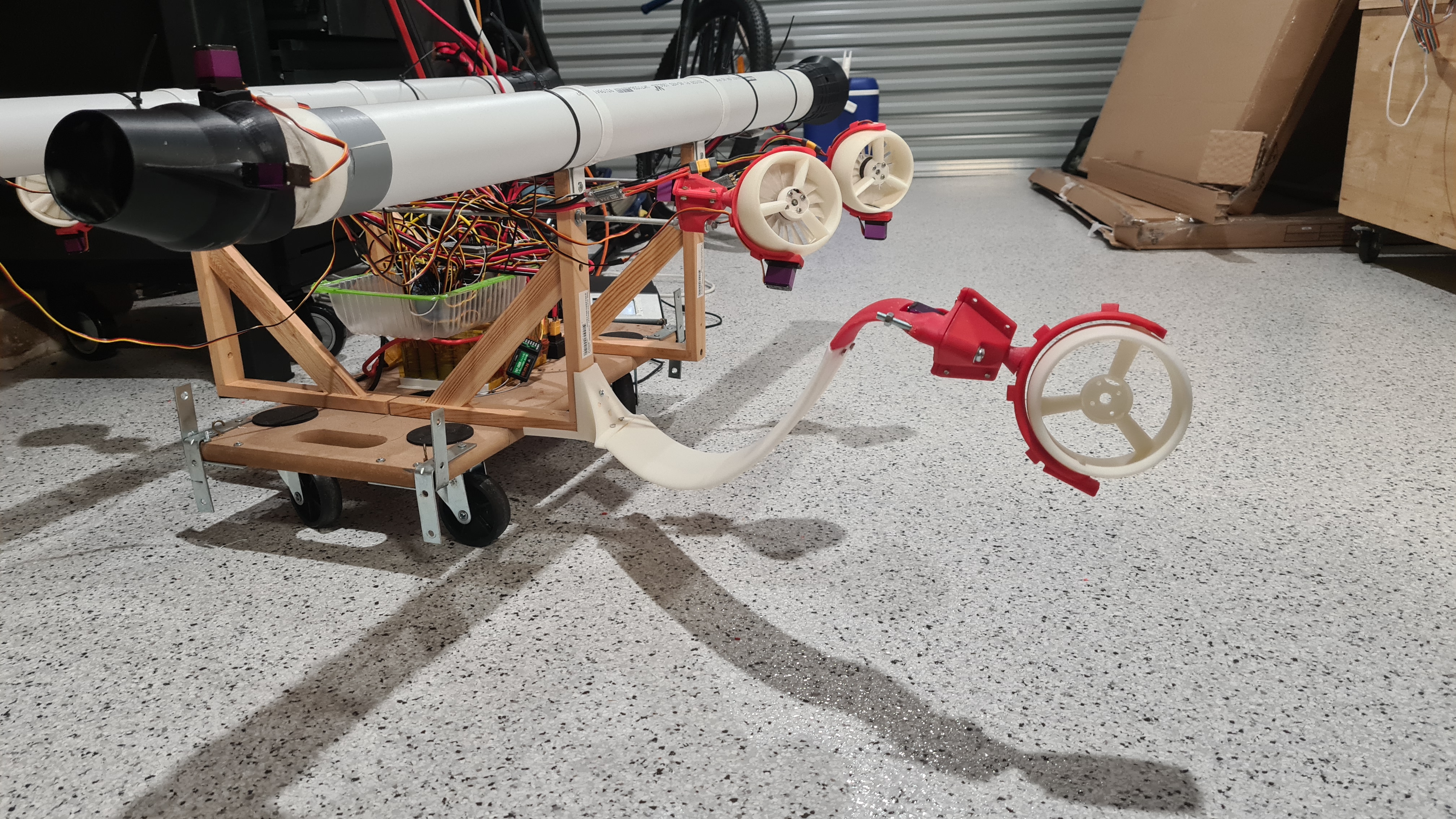

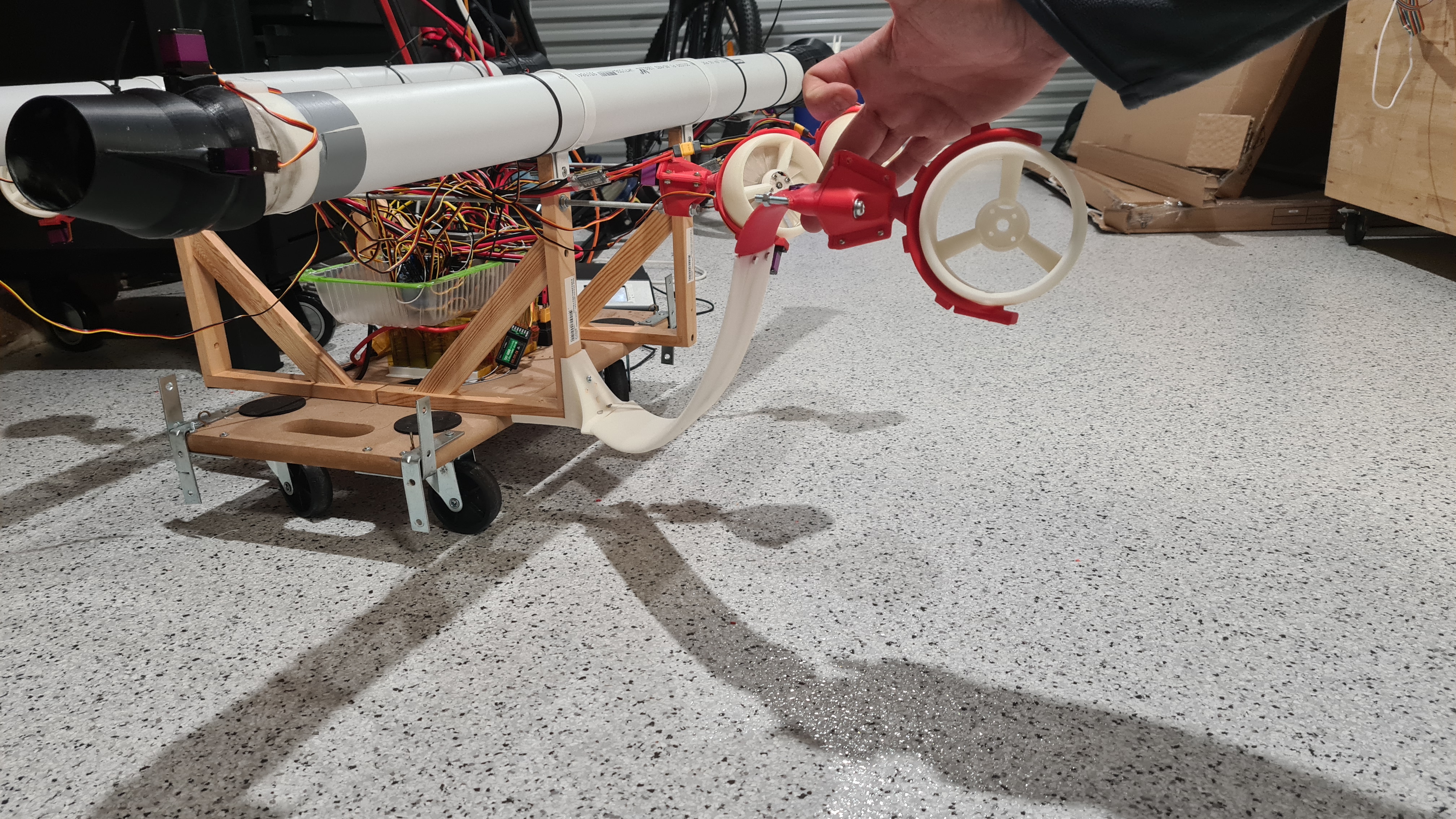

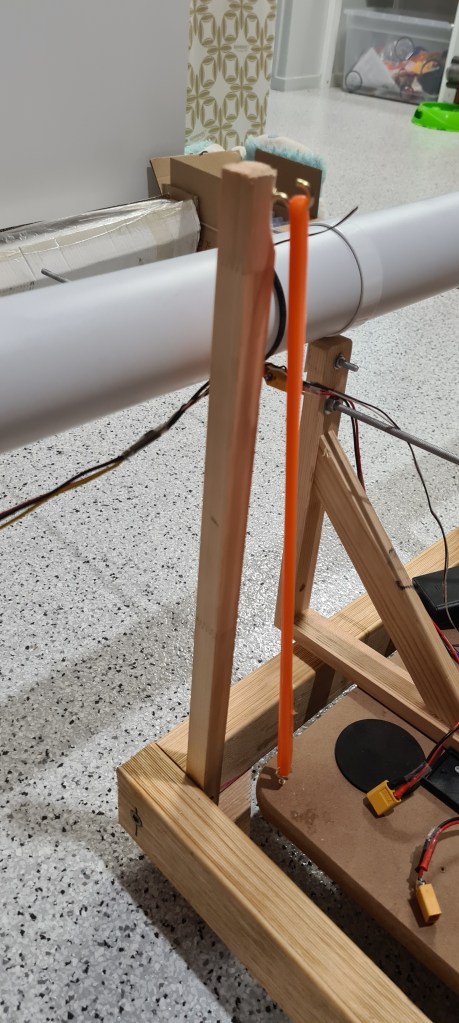

Gimbal arm Mk I

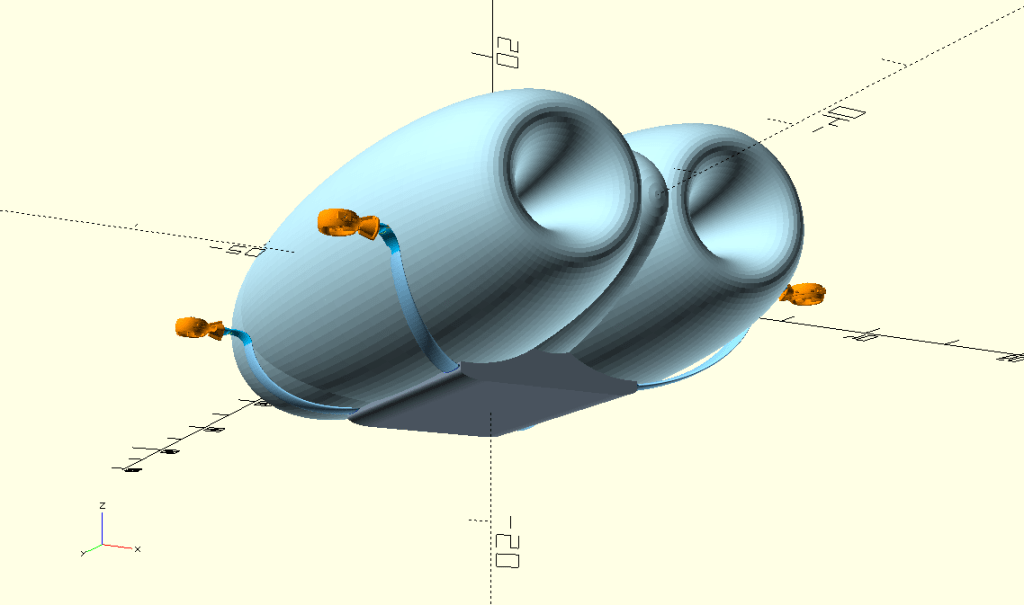

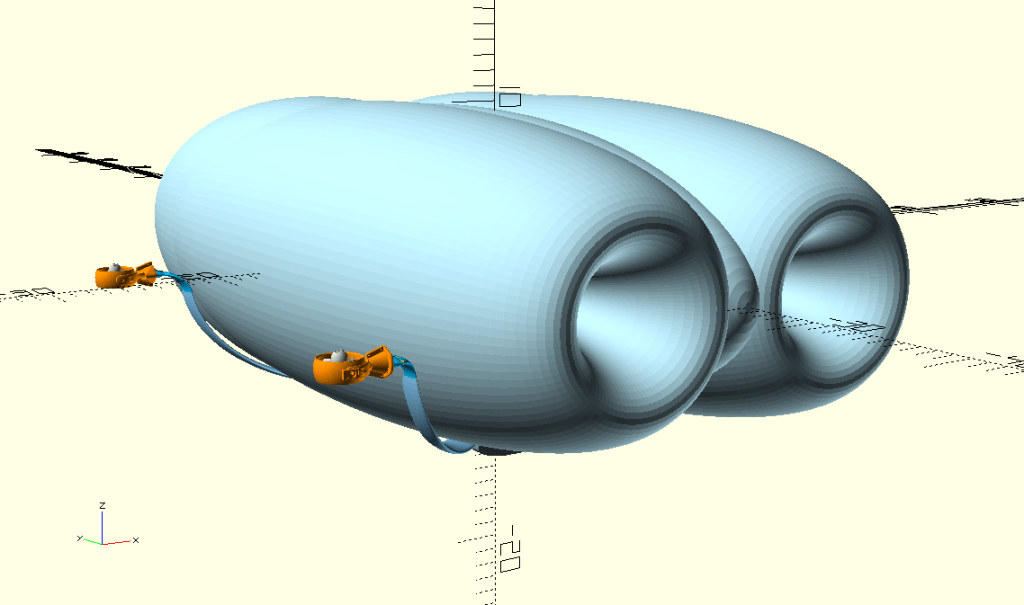

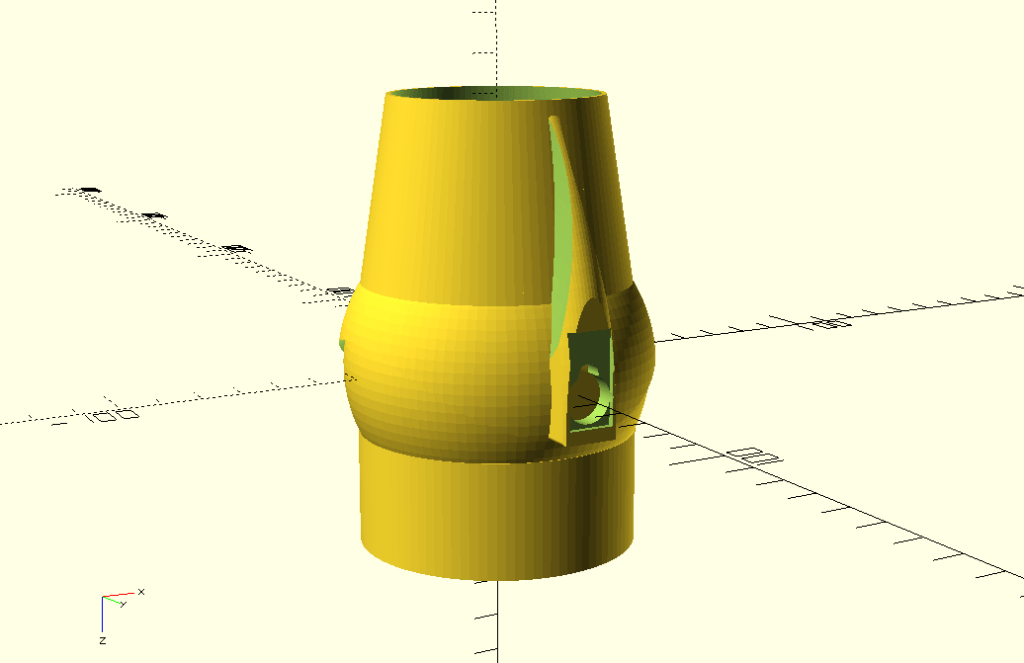

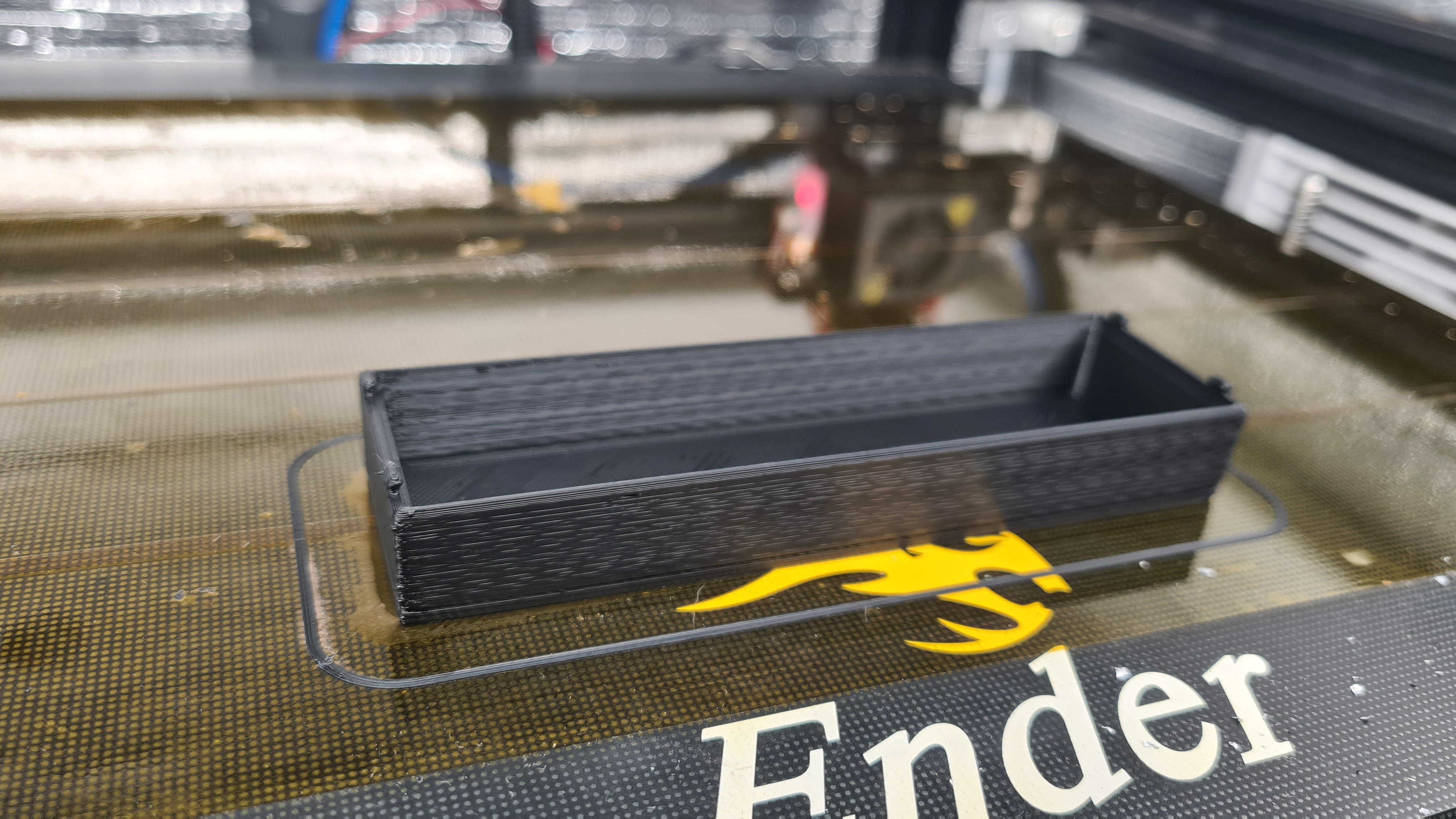

As softly indicated in our Rendering post, our current focus is on designing a gimbal arms. These will serve to extend gimbals configuration away from gondola and align them with main thrusters.

To be able to print such a monster (60+ cm end to end) it got separated in three sections.

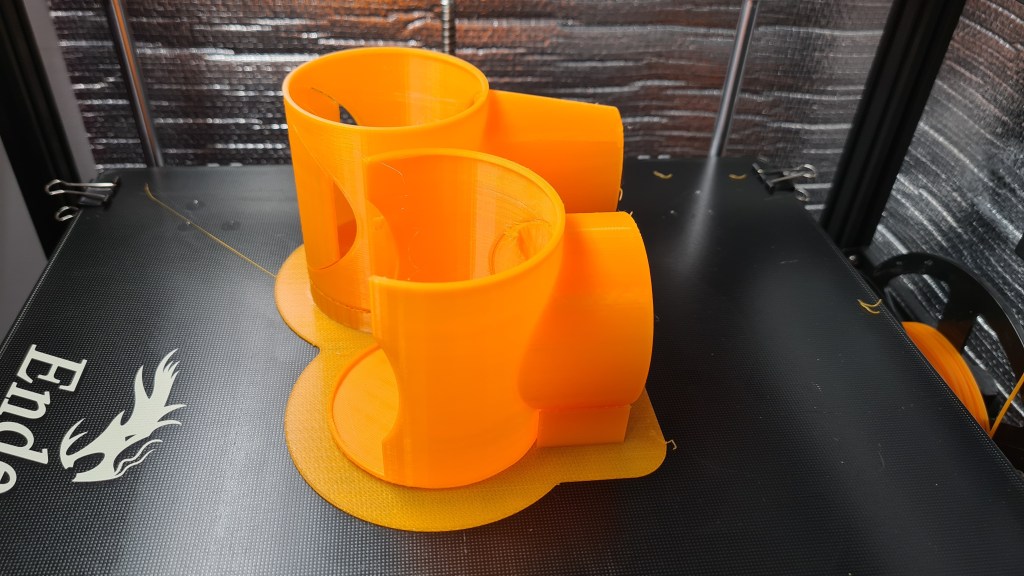

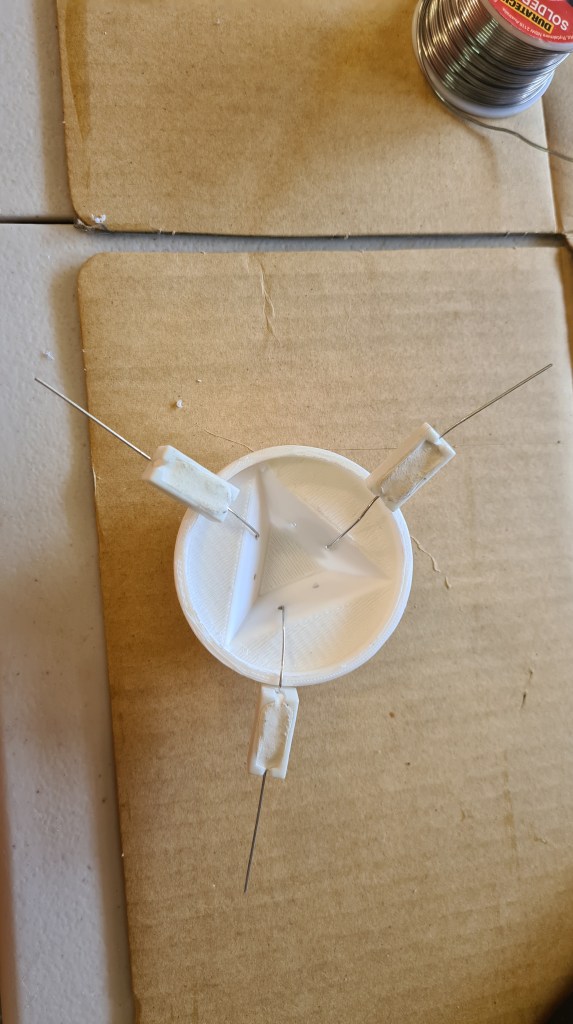

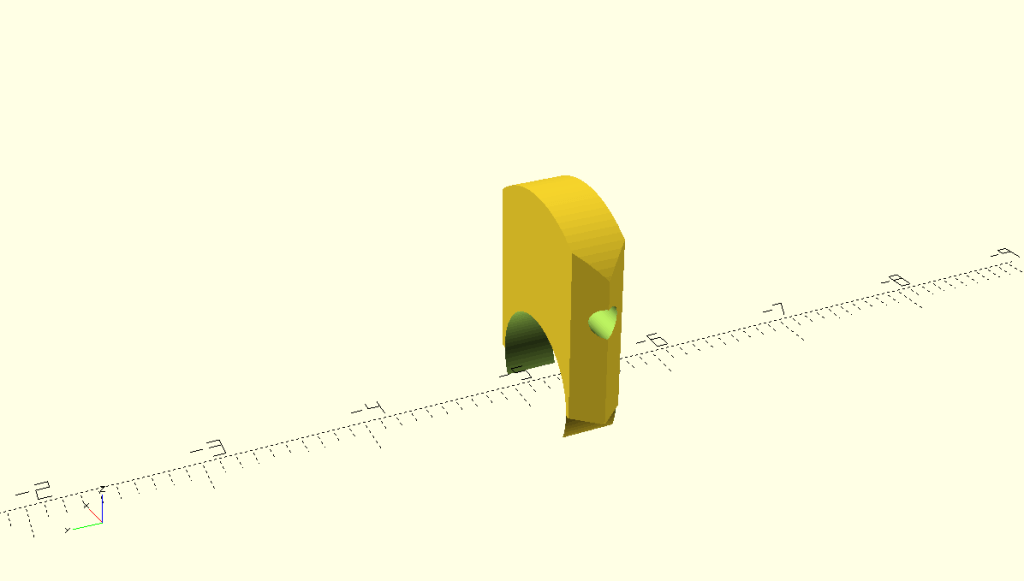

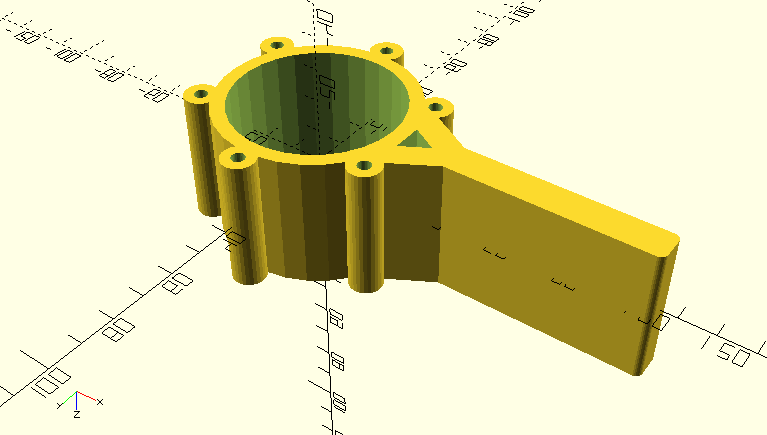

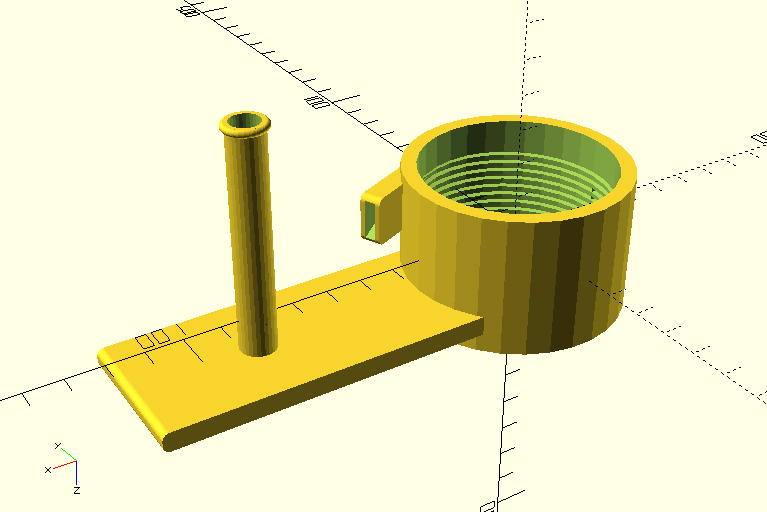

1/ The gondola clamp

I think that pictures will tell more than explaining here what and how.

Overall this clamp is pretty stable and does the job, however joint with that mid-section is too klanky and needs re-designing.

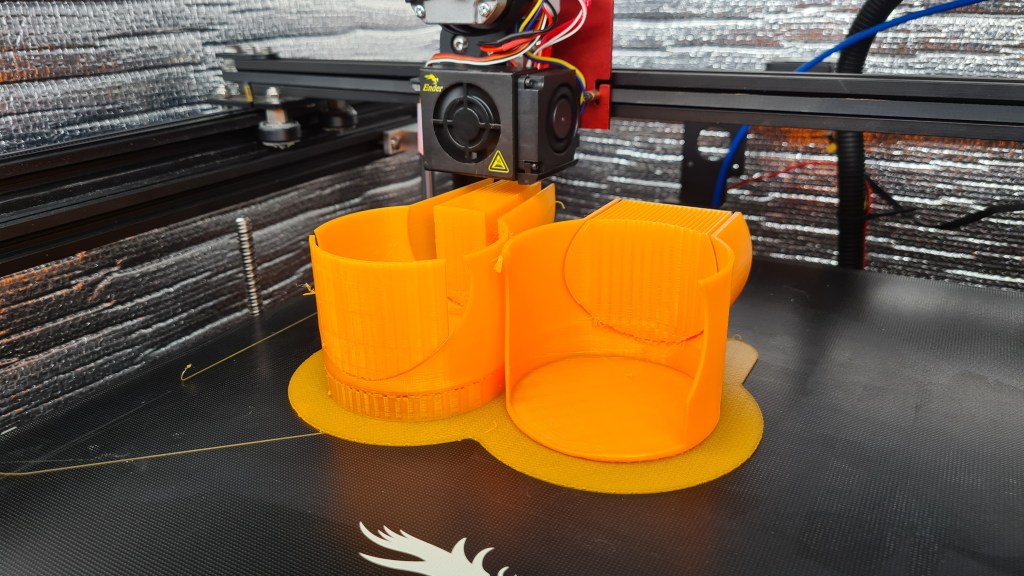

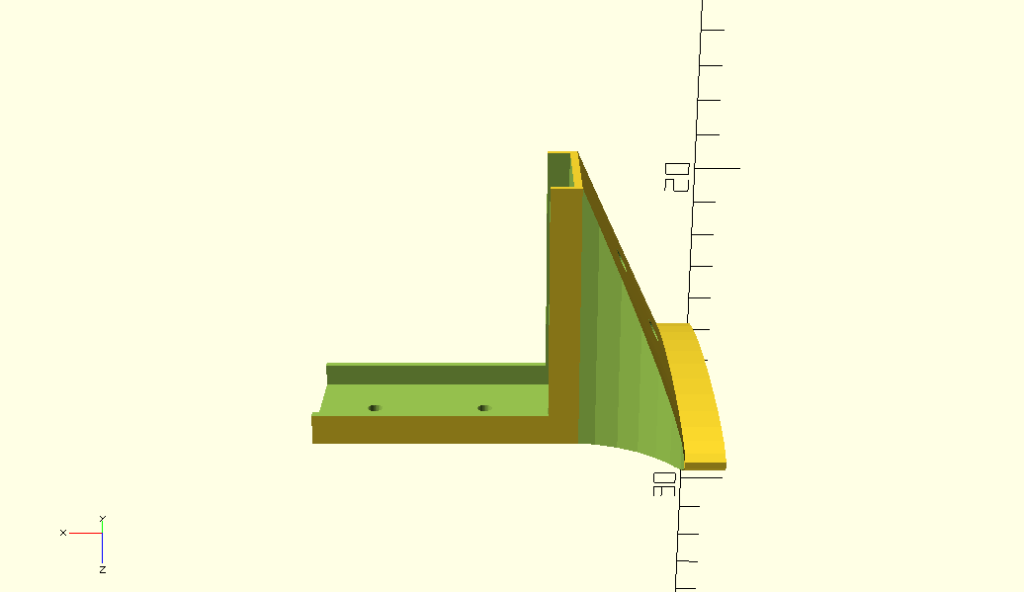

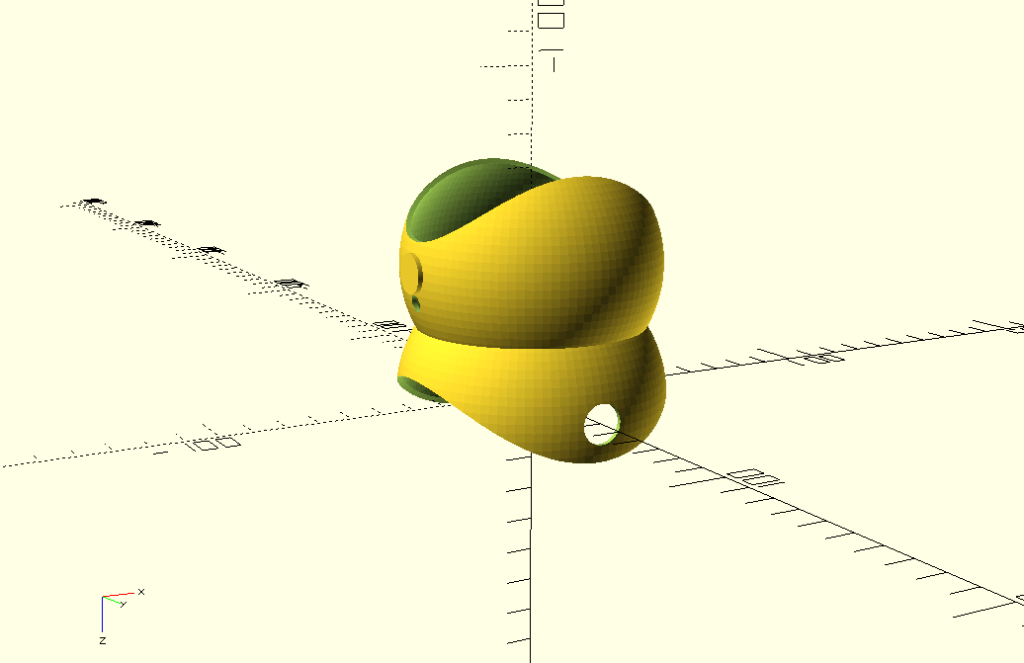

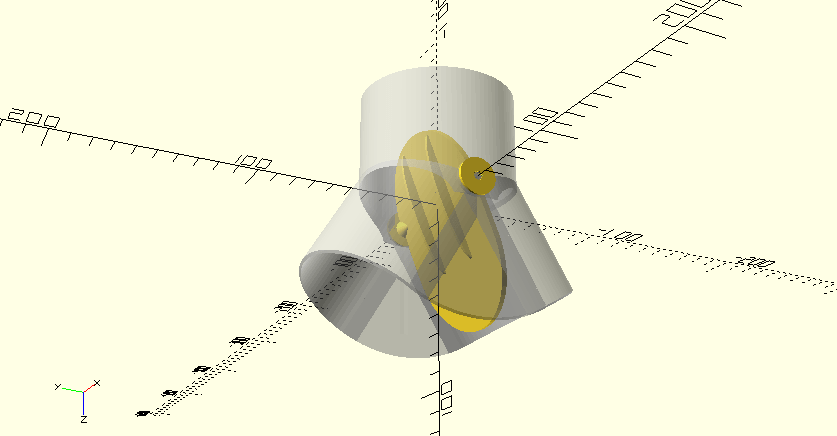

2/ Mid arm section

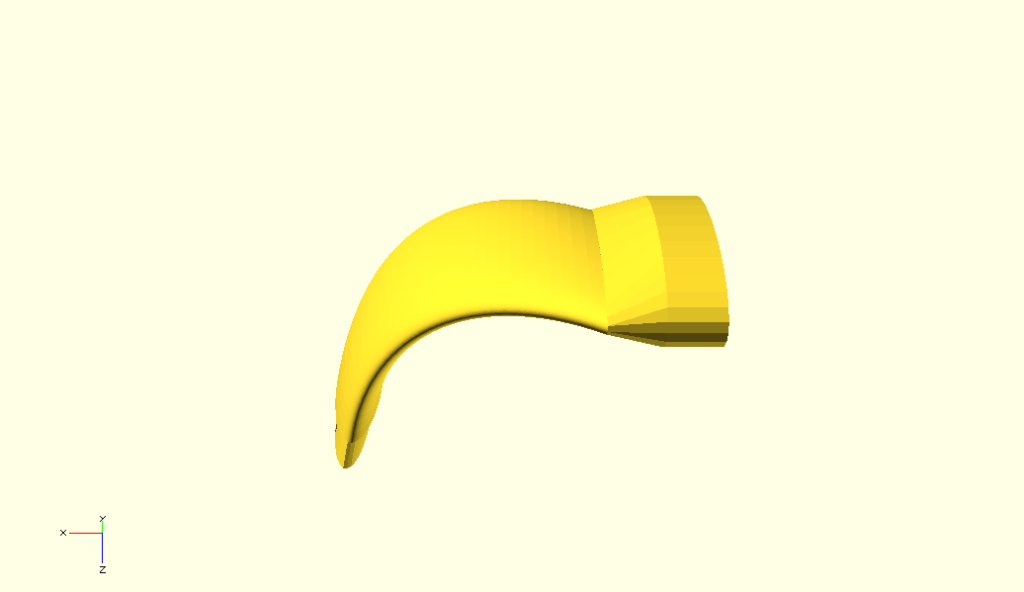

How simple it looks, it took several hours to design a shape which starts with ellipse cross-section of one size (6cm) and skews sideways into another ellipse of a different size (4cm). I am not going to spam here with a code for the others, but I am actually pretty proud of this part so here it comes!

fn=32;

#parameterised 2D ellipse

function ellipse(r1, r2) = [for (phi = [1 : 1 : 360]) [r1 * cos(phi), r2 * sin(phi)]];

module tube(r1, r2, rr, R, th) {

D() {

skin([for(i=[0:fn])

transform(rotation([0,80/fn*i,0])*translation([-R,0,0]),

ellipse((r1+(r1-r2)/fn*i)/rr, r1+(r1-r2)/fn*i))]);

assign(r1 = r1-th,r2 = r2-th)

scale([1,1.2,1])

skin([for(i=[0:fn])

transform(rotation([0,80/fn*i,0])*translation([-R,0,0]),

ellipse((r1+(r1-r2)/fn*i)/rr, r1+(r1-r2)/fn*i))]);

}

}

module mid_section() {

D() {

Ry(10) {

skew([0, 0, 45, 0, 0, 0])

tube(r1 = 3, r2 = 1.5, rr = 6, R = 25, th = 1);

}

}

}

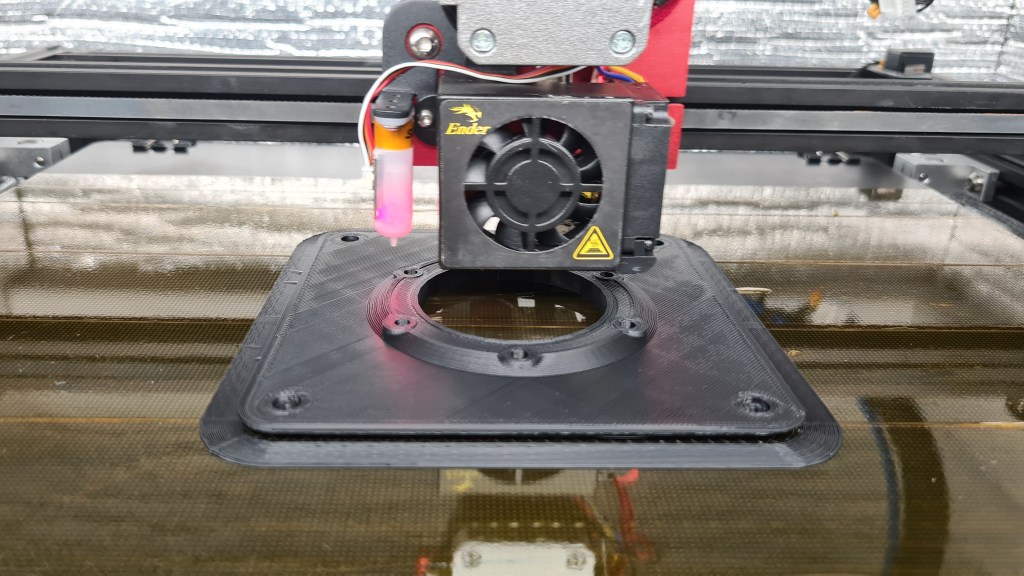

mid_section();Design above allows printing all that monstrosity quite efficiently “laying flat”

It clearly was our longest print so far – it took 18hrs – and seeing how that worked out it already needs redesign. An internal reinforcing rib is needed and joints on both sides needs some sort of clamps to be more solid.

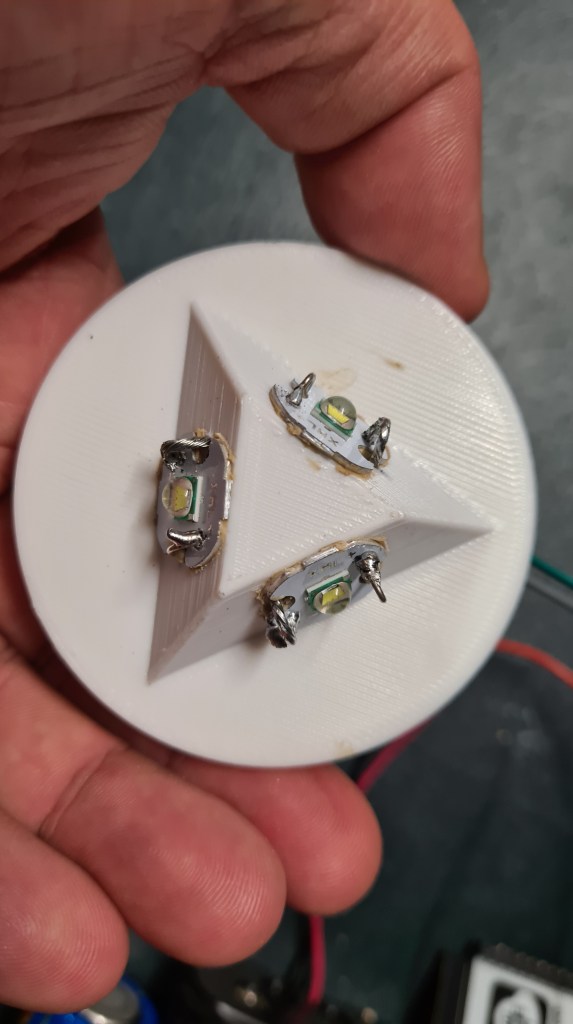

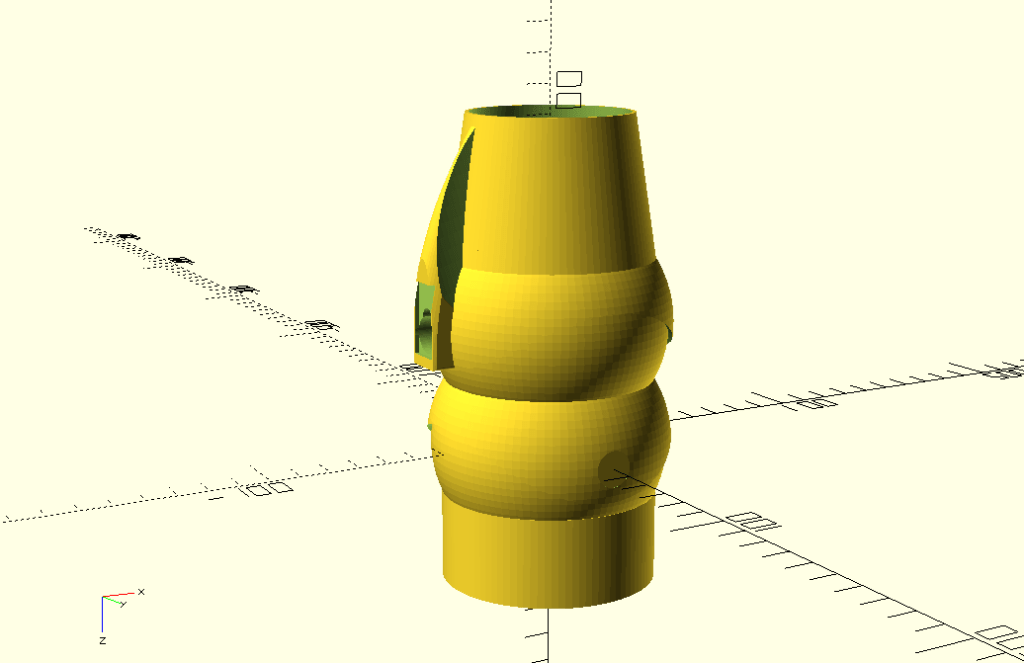

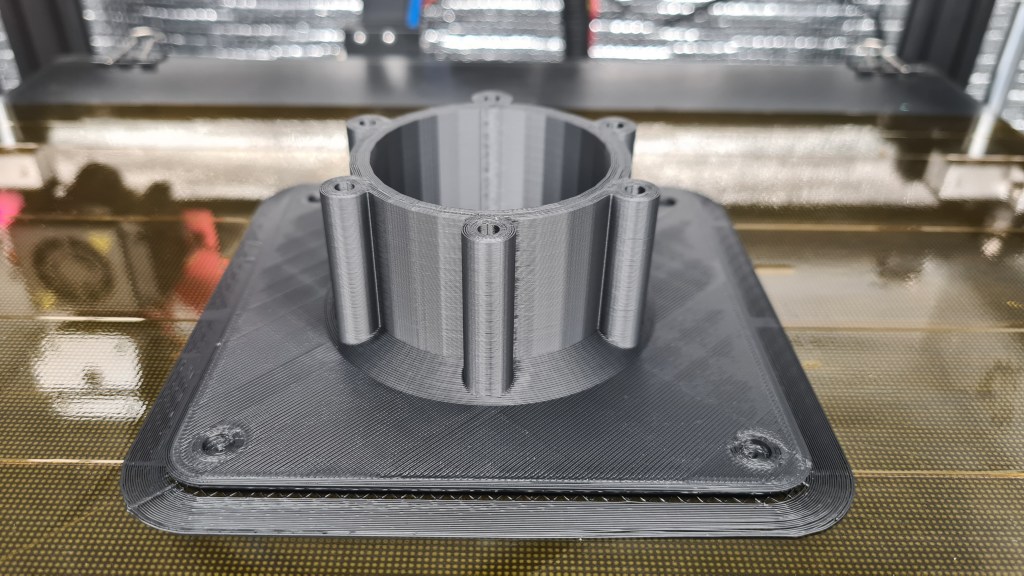

3/ Gimbal adapter section

When having that above mid-section in hands, designing this part was much easier. Practically the same, but smaller + bit of fun when scaling cylinders to make them fit that ellipsoid cross-section. Problematic part came when attempting to join it with the gimbal as there was not enough material to make me confident about it withstand some reasonable sheer forces (400N). Simple “test by Ondrej” demonstrated that I was right.

Video from printing here:

Anyway, at the end it all clicked together (with bit of sanding, heating and persuasion) to the point where we could demonstrate its first prototype!

As you can see above, there is quite a sag on that arm which is caused by multiple design weaknesses, but mainly the joint between the main clamp and the long arm. That needs to be surely reinforced. I am still liking it as it really looks pretty close to that original rendering, just this is real! 😀

As always, let us know your ideas or any comments whatsoever, all welcome!

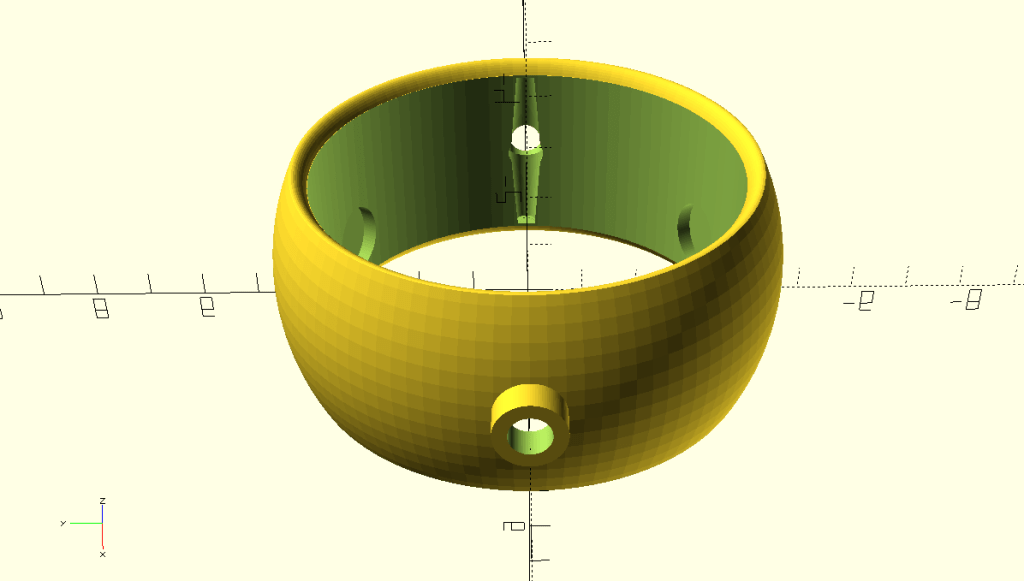

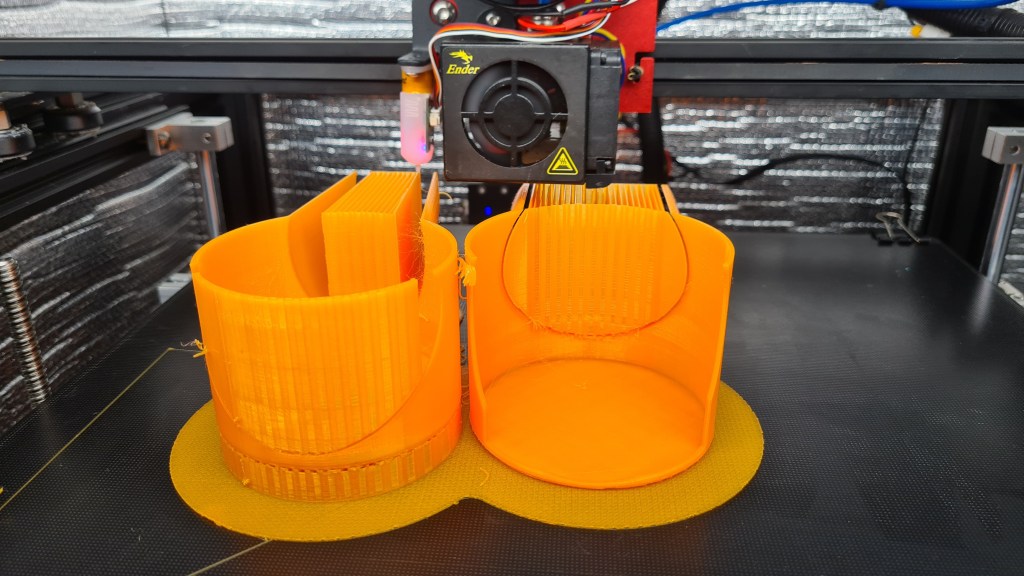

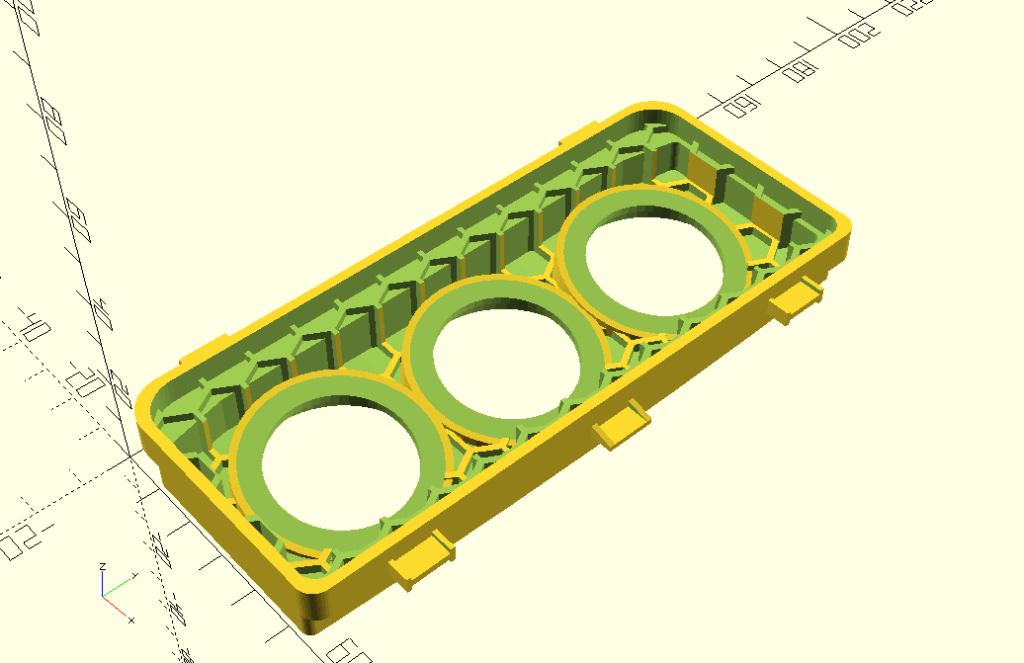

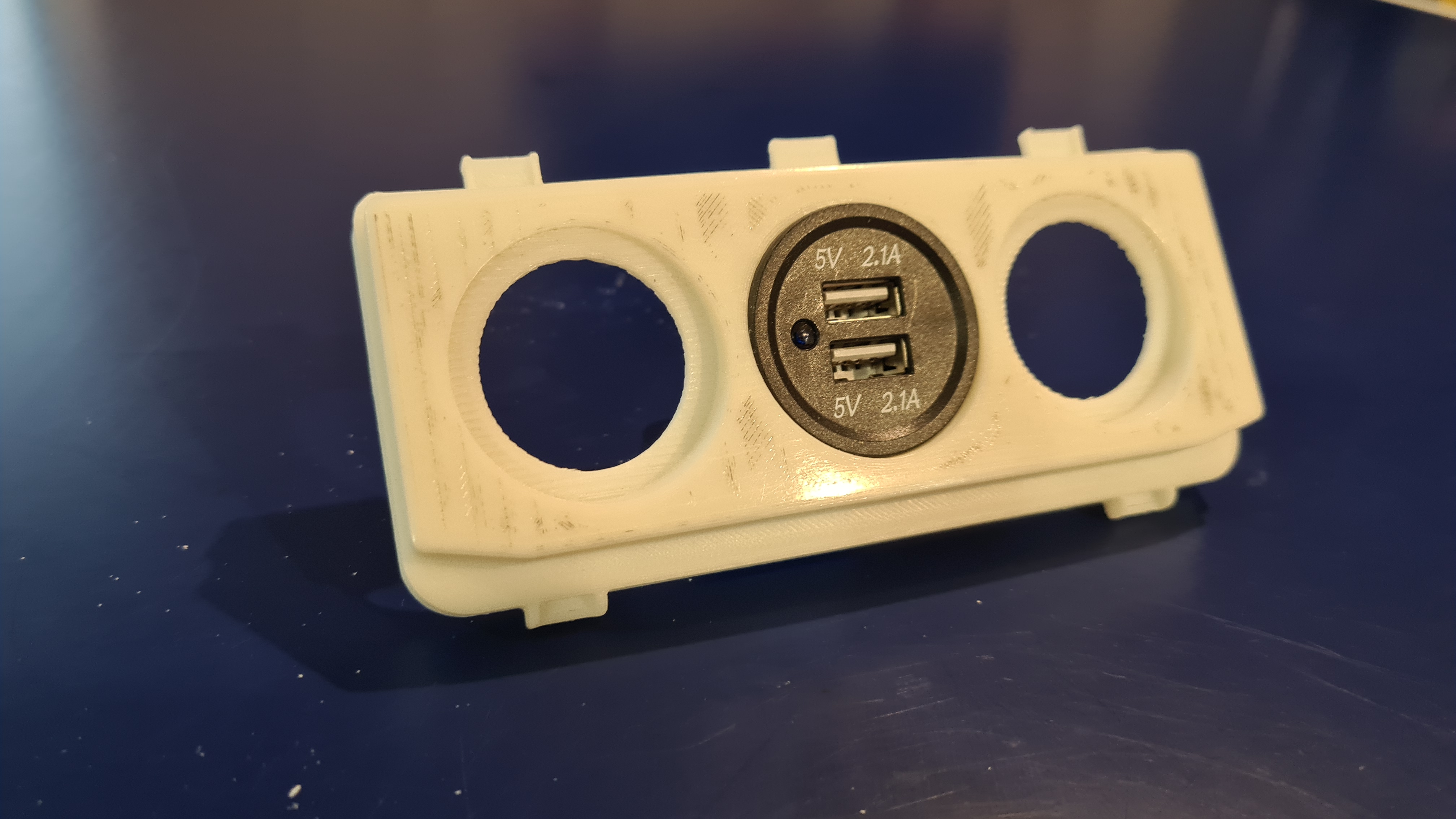

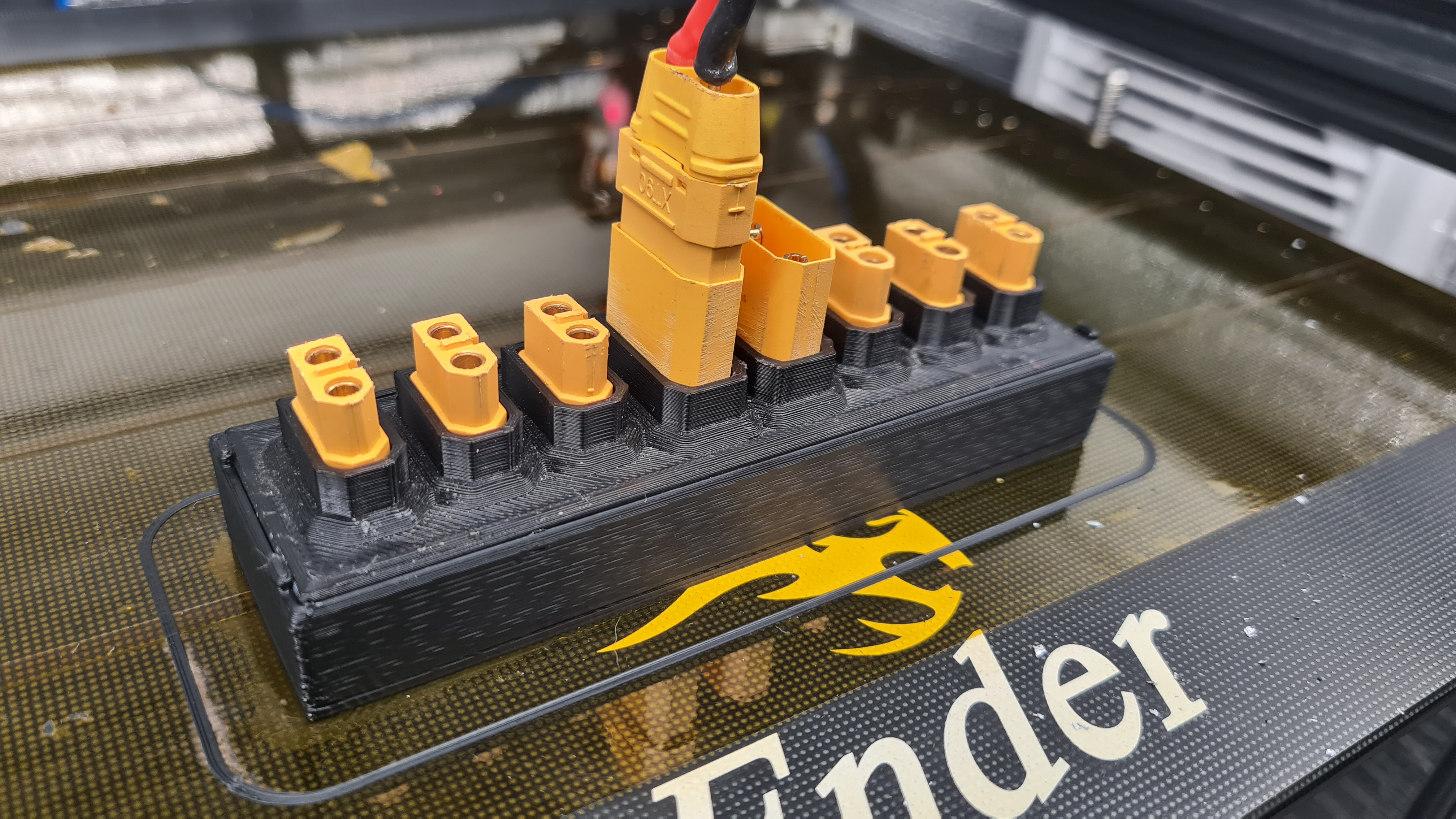

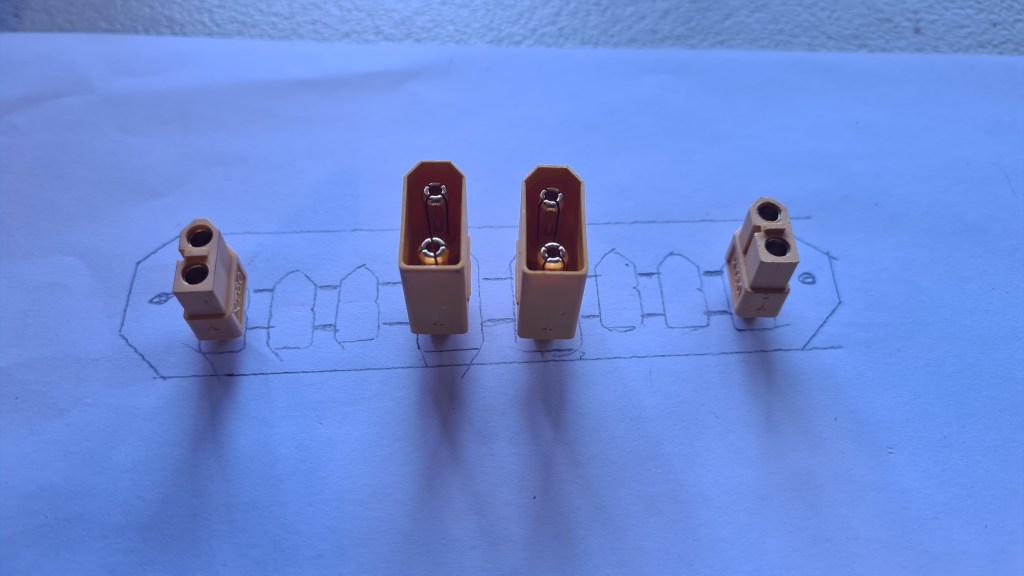

3D part for Vilda’s car

Vilda, knowing that we are having too much fun with our 3D printer, asked us for a favour and improve one of his car’s slots with power sockets. Well me, knowing that Sebi is having too much fun with our 3D printer, asked him to do that job for Vilda! 🙂

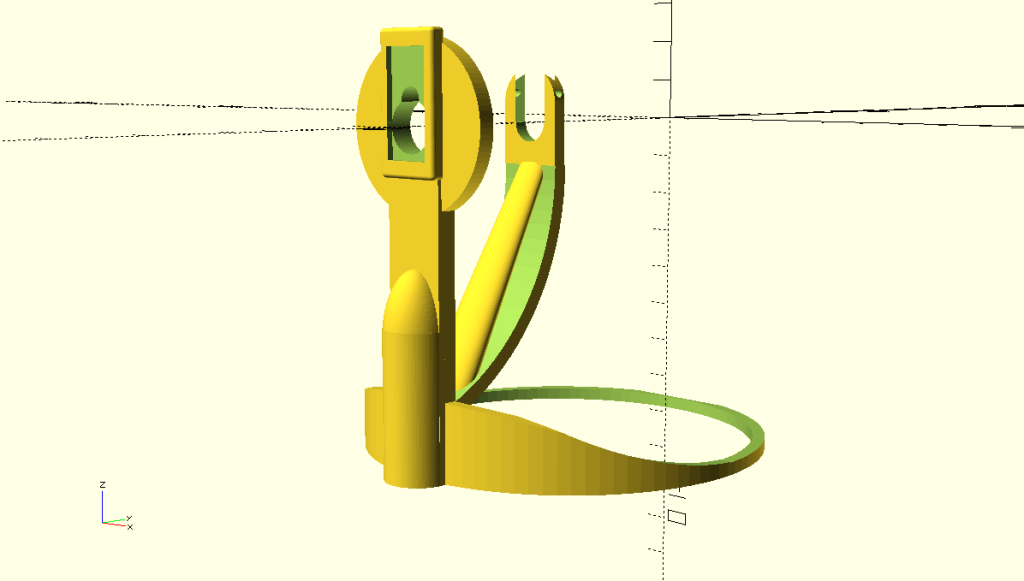

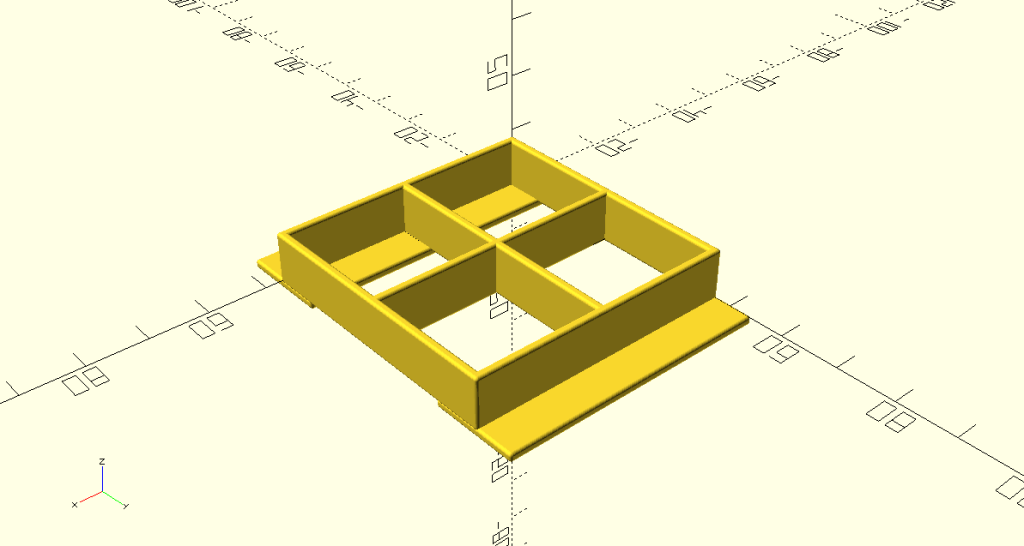

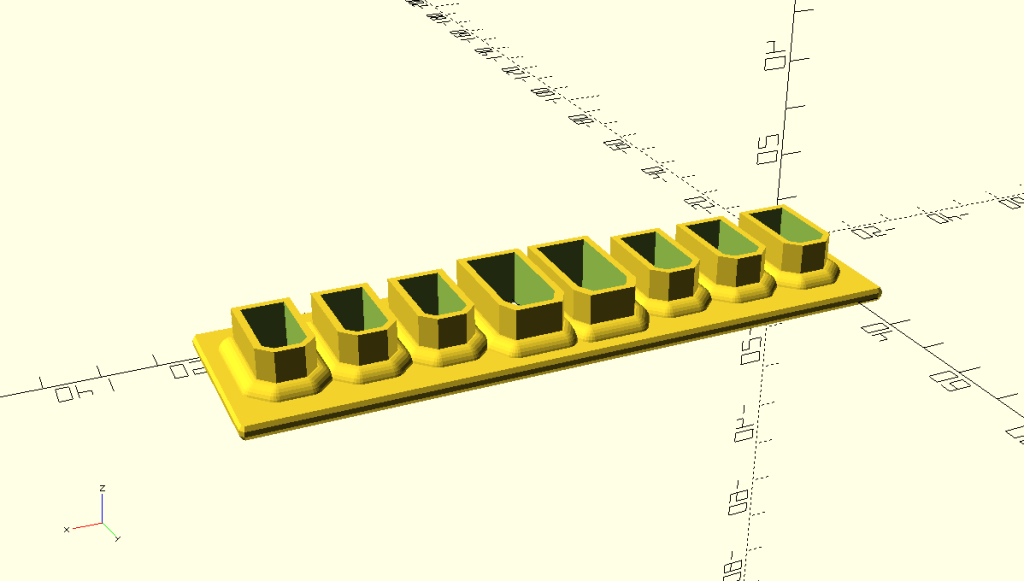

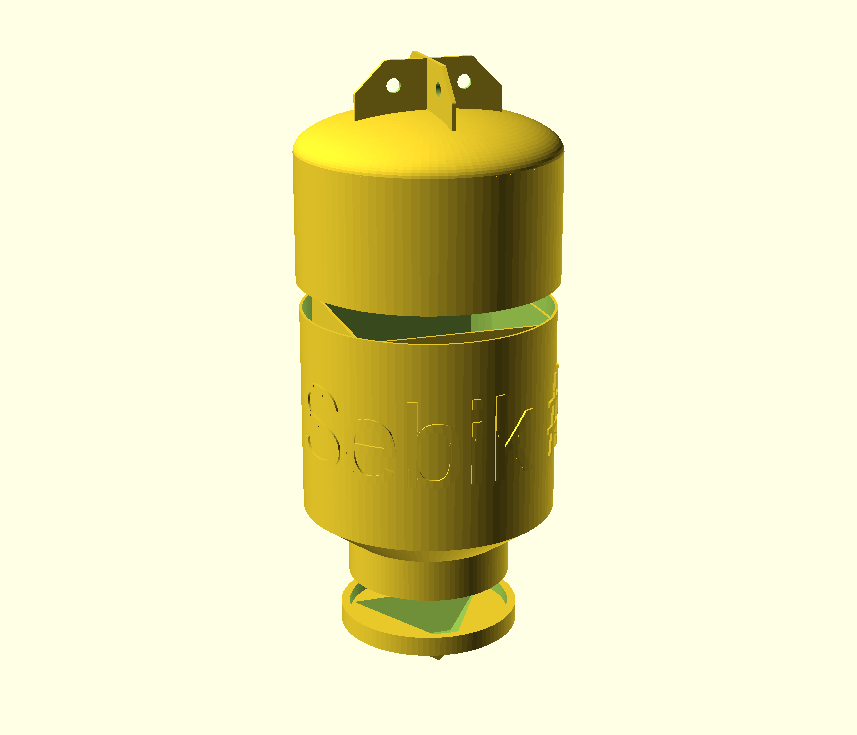

Anyway, Sebi spent few day on in and it worked out so well that I decided to document it in one of our posts. Here comes screens from OpenSCAD.

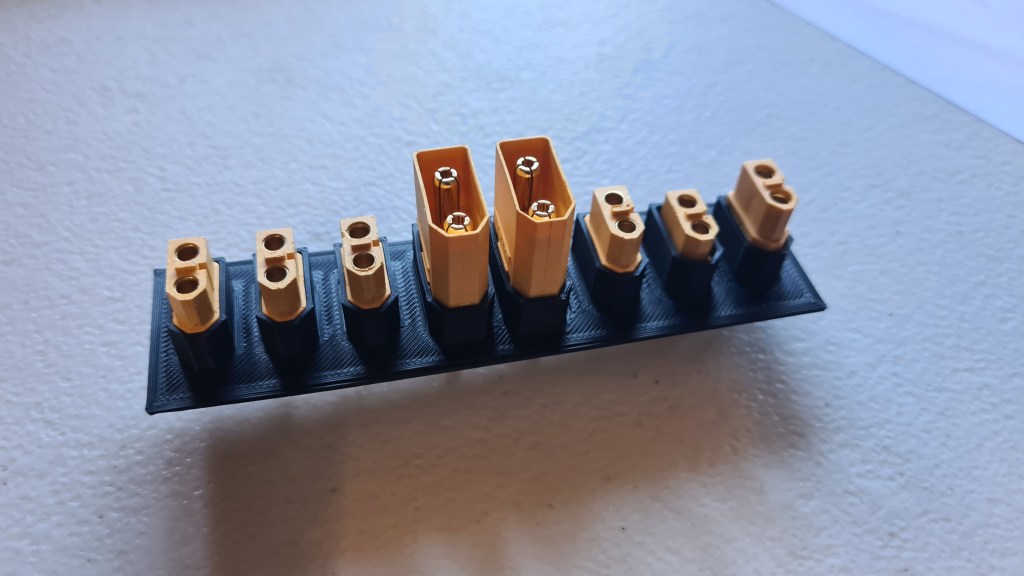

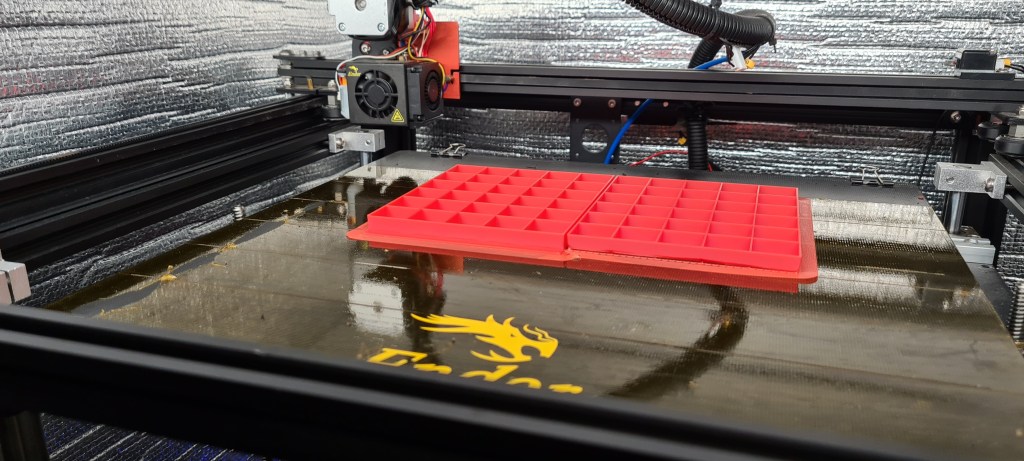

This is how it worked out in a slicer (CURA).

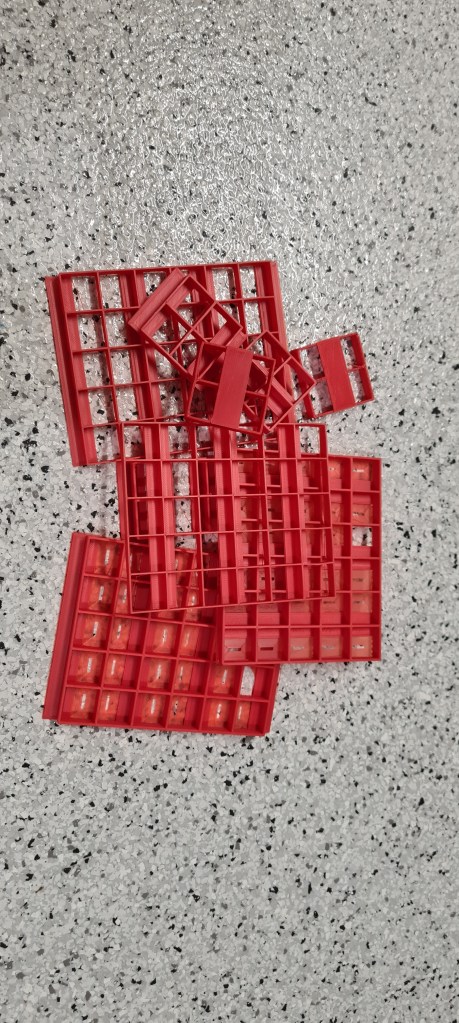

As always it took “just” few hours to print it and we’ve ended up with a final product!

Vilda mounting it in his car.

Unfortunately edges haven’t had the same radius, but nothing Vilda can’t fix with bit of sanding 😉

Well done Sebi, this looks like a pretty good job done!

UPDATE 3rd Jul 2022 – Vilda provided several pictures from a final assembly – Thank you Vilda 🙂

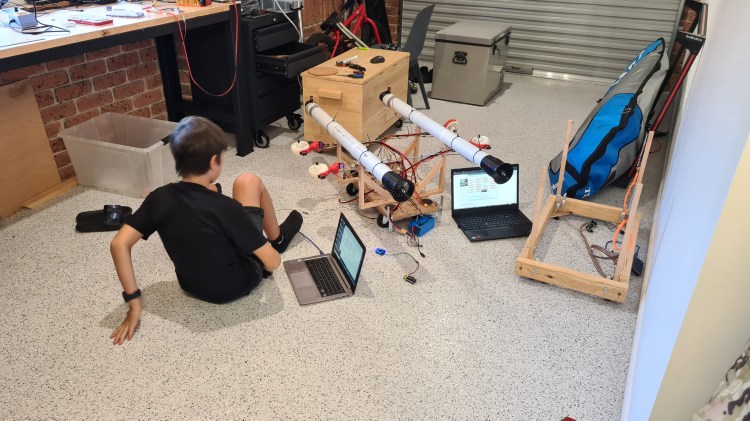

Vectoring Thruster 3D – Update

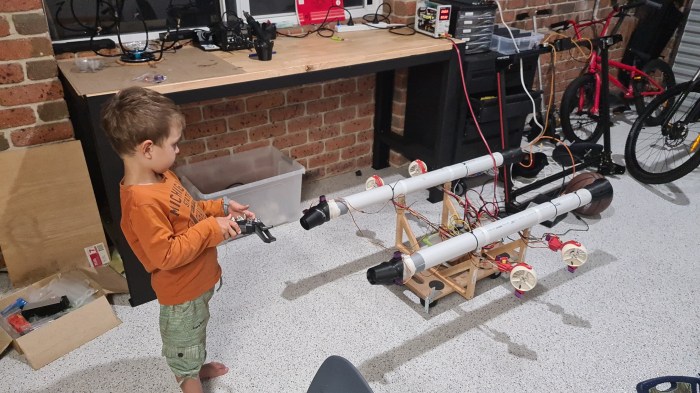

It took a while, but we have those new Vectoring Thrusters working! I’ve asked our new airship engineer Filip (4yro) to give it a go and he did an excellent job demonstrating its operational – with confidence. 🙂

Thank you Filip! 🙂

And now Sebi, with engines … enjoy the rumble!

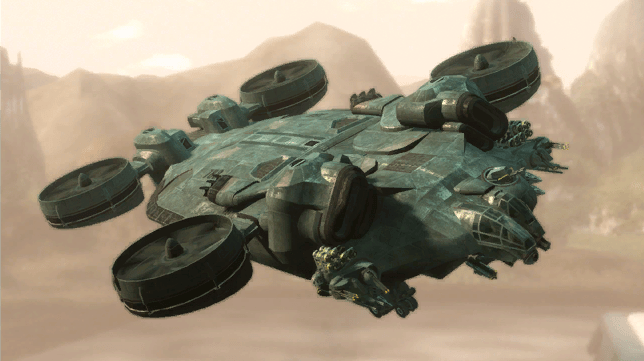

Renderings

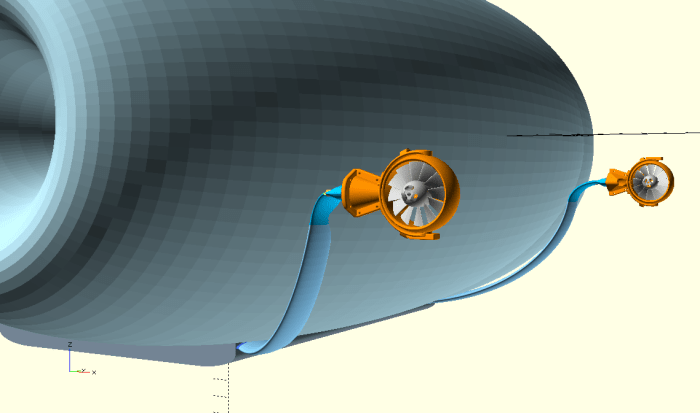

I did few updates to our main design in a model model preparation for some experiments with OpenVSP. Seeing how that worked out nicely, I took several pictures and prepared them in a small gallery, including tiny comments.

Front view, all three envelope segments are nicely aligned, showing two main intakes. Gimbals are bow-facing on sides, attached to a gondola with wide bent arms copying a shape of the envelope.

Side view – two gimbals hanging on long arms demonstrating those being skewed to get a cruciform (quadcopter drone, but in style).

Rear view, vector thrusters are not present, but those will be located in a centre of both side envelopes. (Central envelope has no duct, it serves as a ballonet.)

Isometric (from below) view – I just like how it comes together on this picture, but it also serves as a reference for the following one.

Same picture as above, but notice gimbals are now up-facing.

Same trick as above, just a different viewpoint.

I took one more showing forward-facing gimbals in this angle.

Well, this is something different – envelope is missing here to provide better overview of gimbals orientation. Gondola is just a placeholder here, but demonstrates that it’s main part is hidden in the airship body to lower its air resistance.

Now this is our holy grail, our airship transformed in a drone (gimbals are facing up)!

The final one – close take on gimbals. I think they look pretty impressive mounted like this!

Well, as always let us know what you think! All (constructive) comments welcome. 🙂

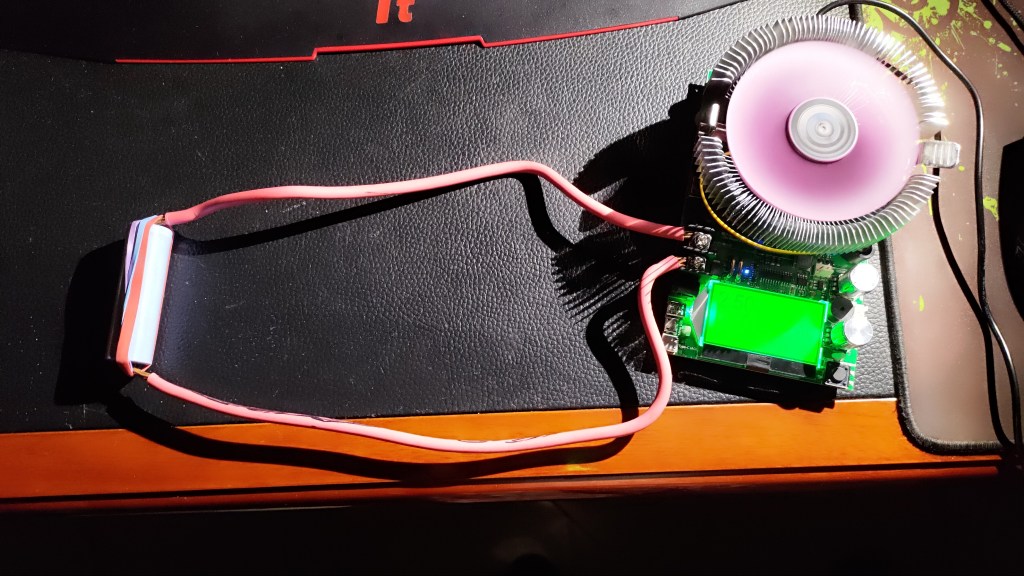

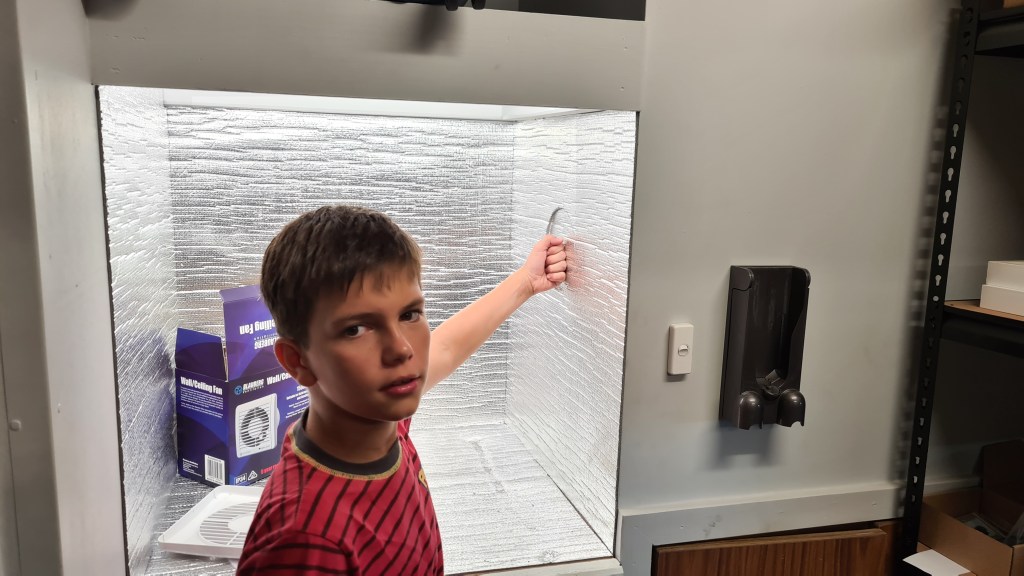

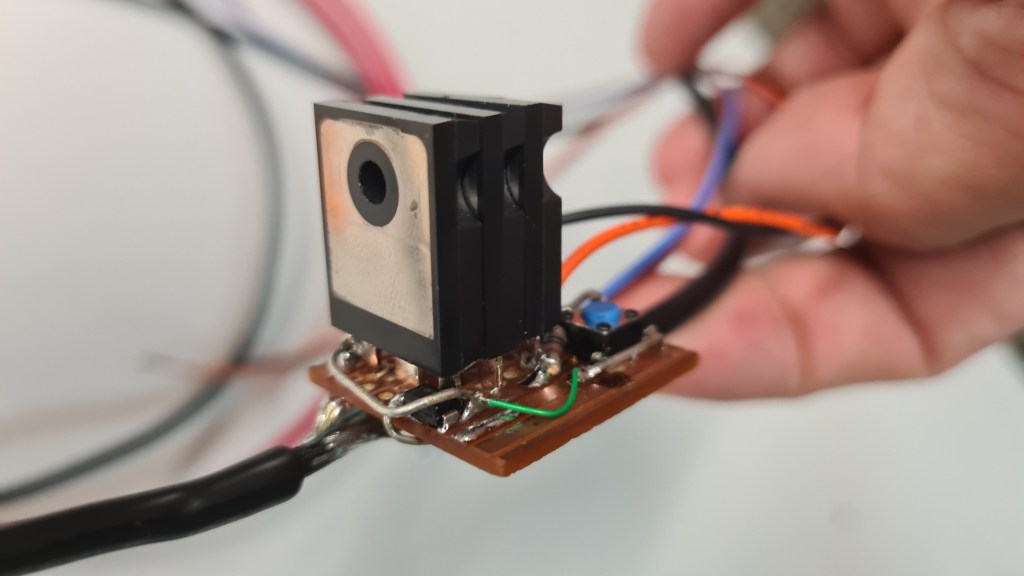

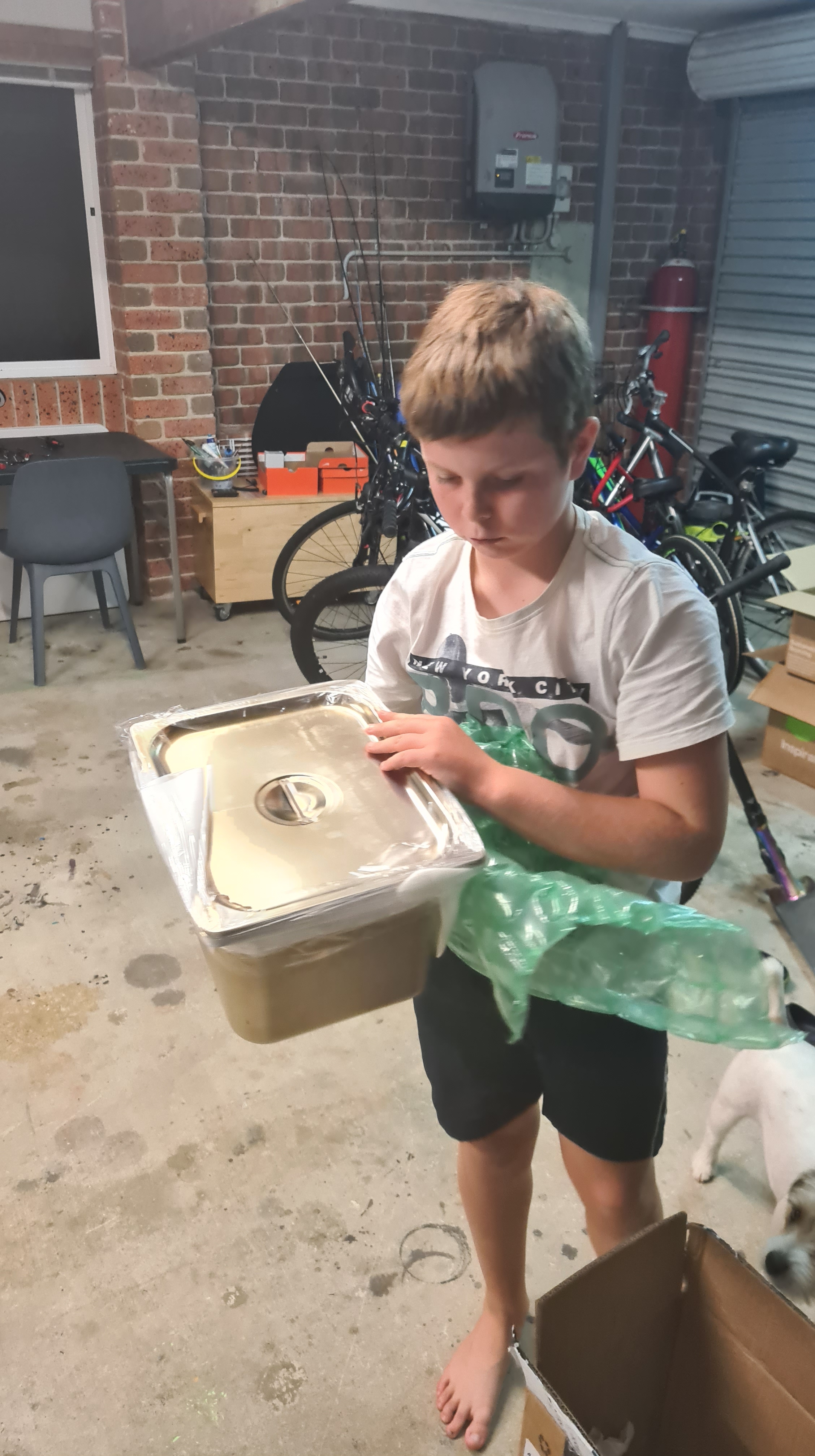

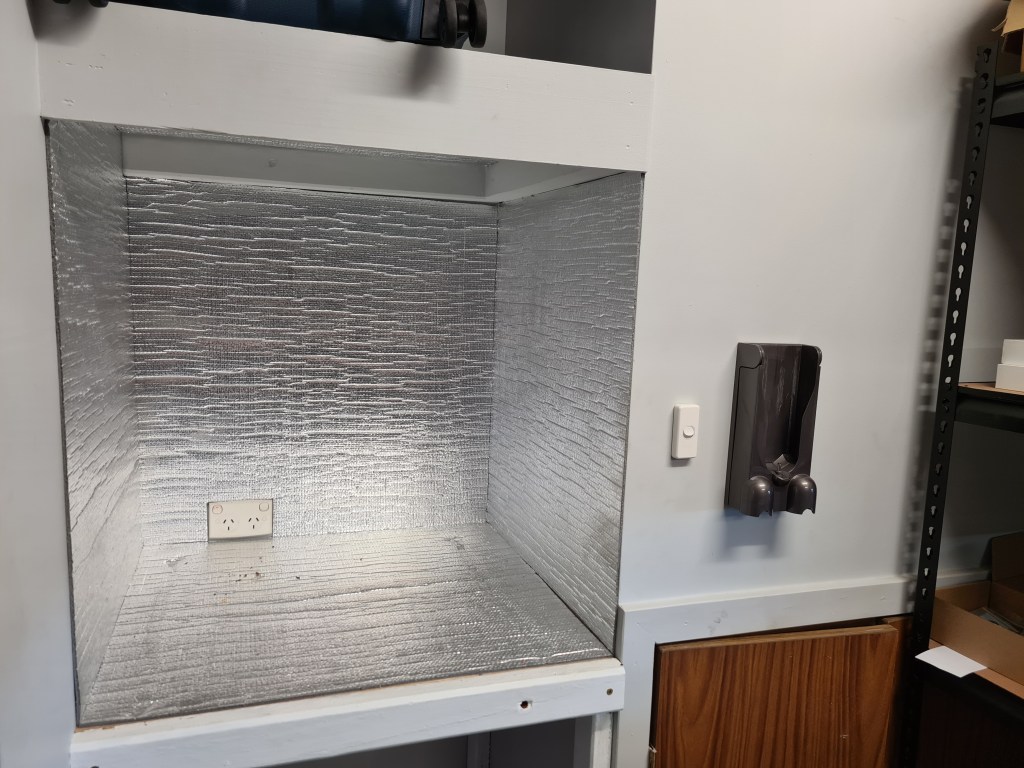

Thoughts on heater for Carbon Fibre curing

I’ve been discussing how to build a heater for our Carbon Fibre curing with Serge and he proposed to simplify things greatly. Instead of an aluminium tube with a copper wire winding type – he came with a simple cooking heater wire which would be placed in a centre of our tube.

As usual with Serge, he instantly grabbed a spare one and gave it a try! 🙂

It is awesome & thank you Serge! This really solves more than a few things – even wire winding, fitting tube in a tube, mechanical protection of a wire, temperature control and also simplifies our design quite dramatically!

Still, I made couple notes which we need to think through:

- How to secure this element in a middle of our tube, while avoiding any (significant) thermal bridges?

- We need to come with some sort of automated temperature control to keep constant 175C for 40 minutes

Once again, Thank you Serge!!!

Starting a PIc

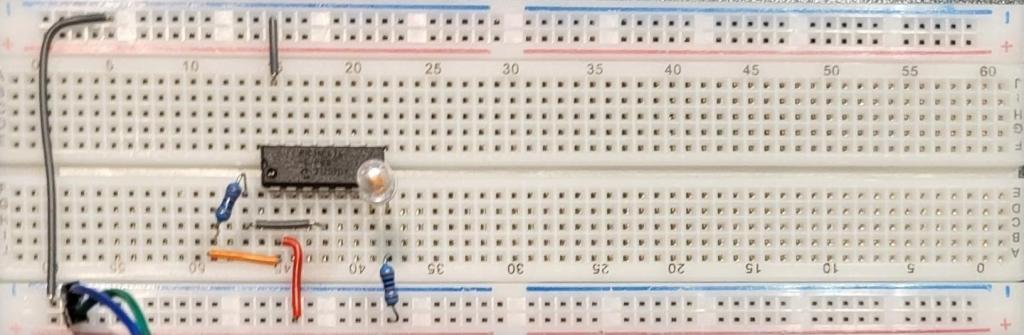

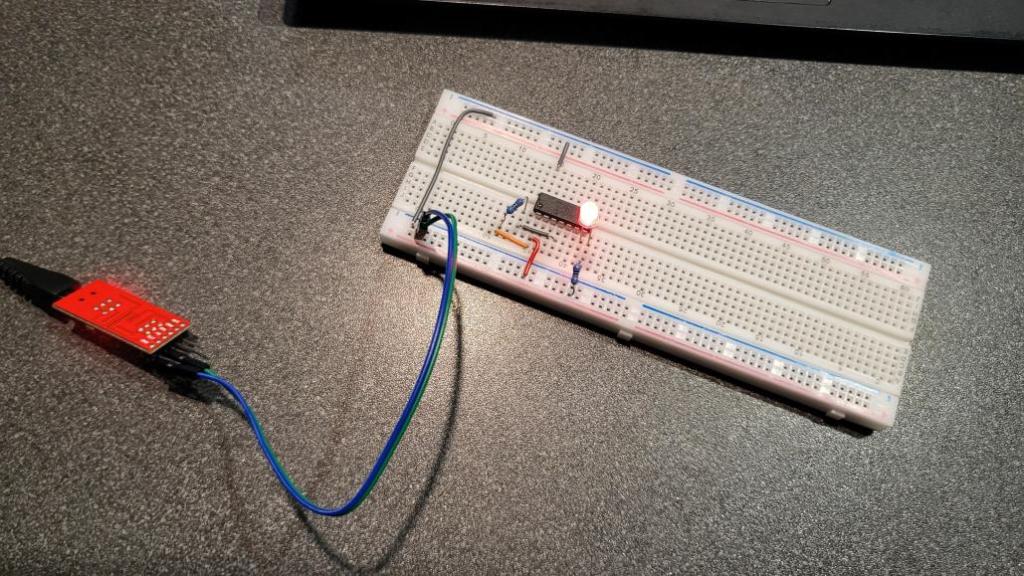

PIC microcontrollers are a family of specialized microcontroller chips produced by Microchip Technology in Chandler, Arizona. The acronym PIC stands for “peripheral interface controller,” although that term is rarely used nowadays.

The reason I got into PICs was to experience a low-level world of make it from absolute scratch. If any of the following apply to you, then you should definitely give it a go:

- You want to be able to build embedded projects for very little cost.

- You are interested in learning the inner-workings of a microcontroller.

- You find it satisfying to build something from scratch.

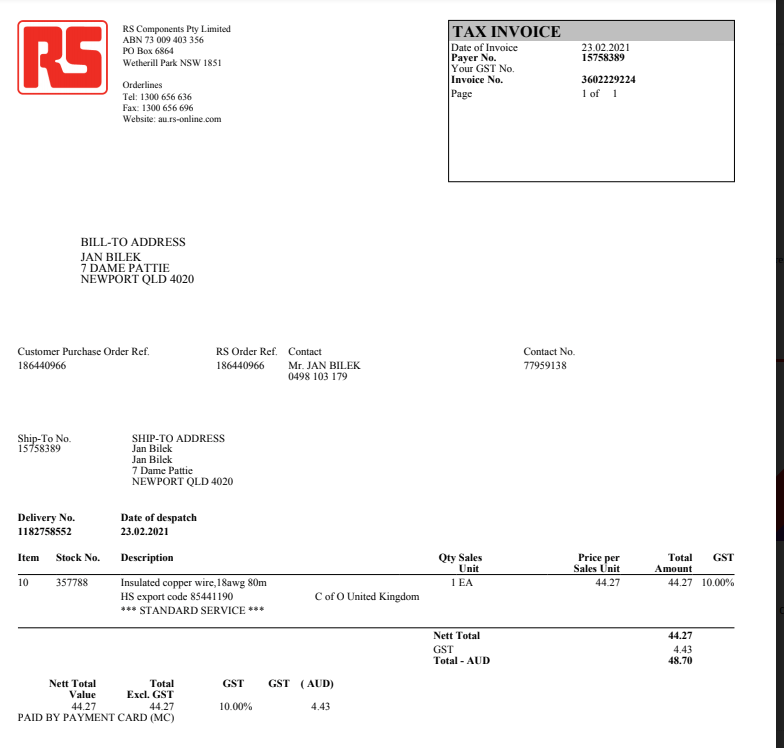

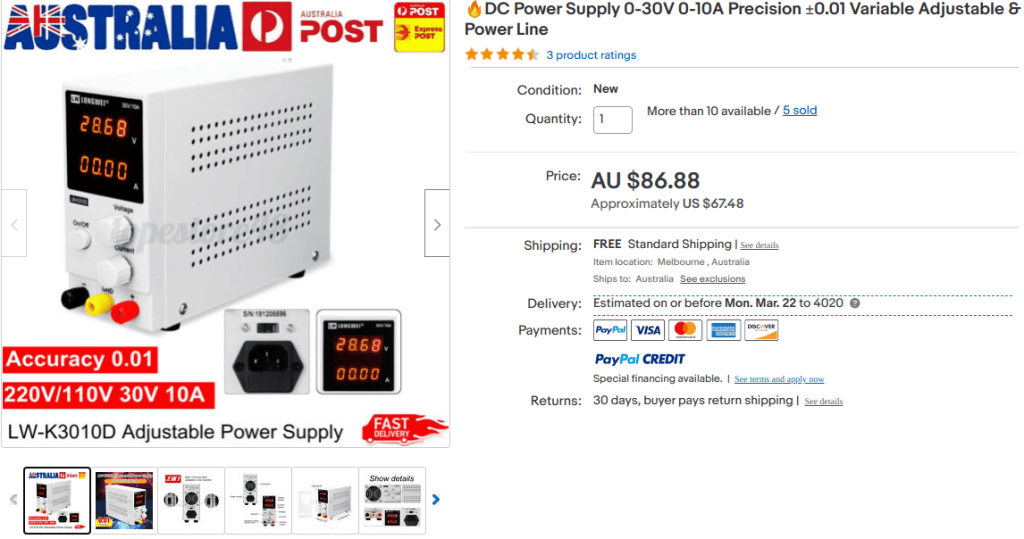

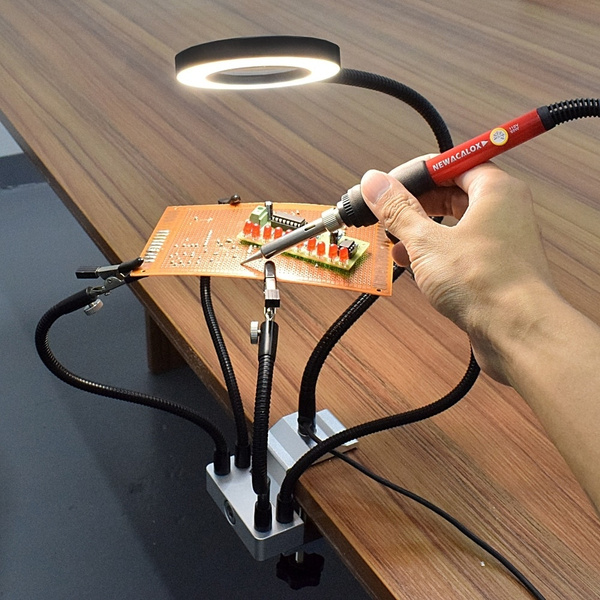

When starting with PICs its a good idea to get one, you can get these from microchip.com or I got my first one and a few others from a local tech store. Alongside a PIC you should also get a programmer, the one I got is the PICkit3.5 which is a slightly improved clone over the original PICkit3, I got it from here: long-link. And with that finally I would recommend a few dupont wires and a power source of 5 volts.

I started with the PIC16F630, however I recommend using the PIC16F690, because it makes it easier to follow the guide I followed: https://picguides.com/beginner/introduction.php

Once you have received all the items and put it all together as per the guide I have a few debugs to address:

- supply enough current! the average PIC accepts about 2 – 5 volts, if you aren’t sure about your PIC it is easy to find in the data sheet as all you need to do is search for operational voltage and the range should be there.

- unlike arduino PICs output ground, this is a problem because if you stick a diode on the wrong way it isn’t going to work so keep this in mind.

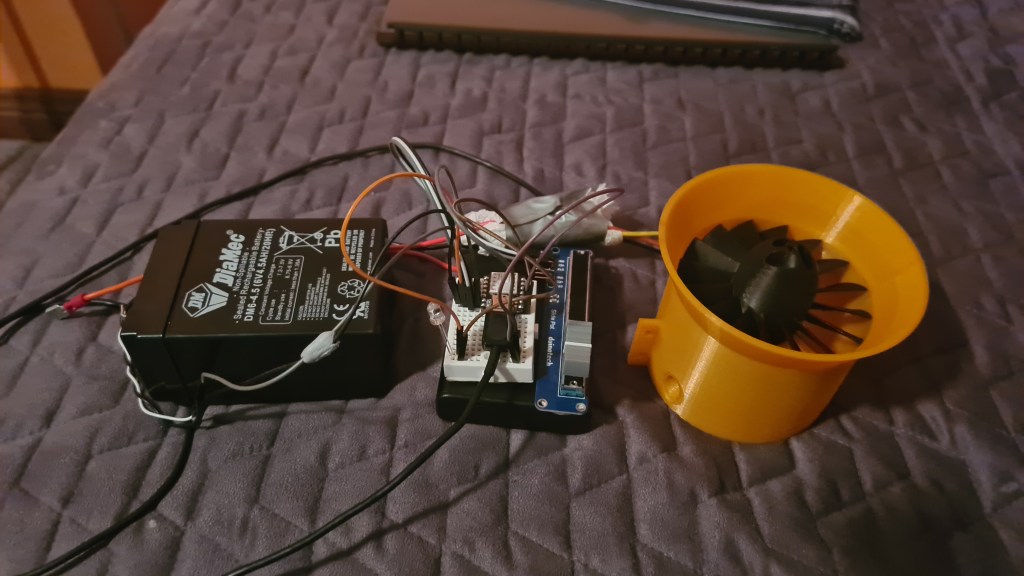

At the end after I have resolved this page of the guide: https://picguides.com/beginner/digital.php, I have ended up with the resulting project:

And that concludes my starting with PICs, Next I hope to create a servo-setter for my dad as he constantly requires me to re-program my arduino for the servo setting.

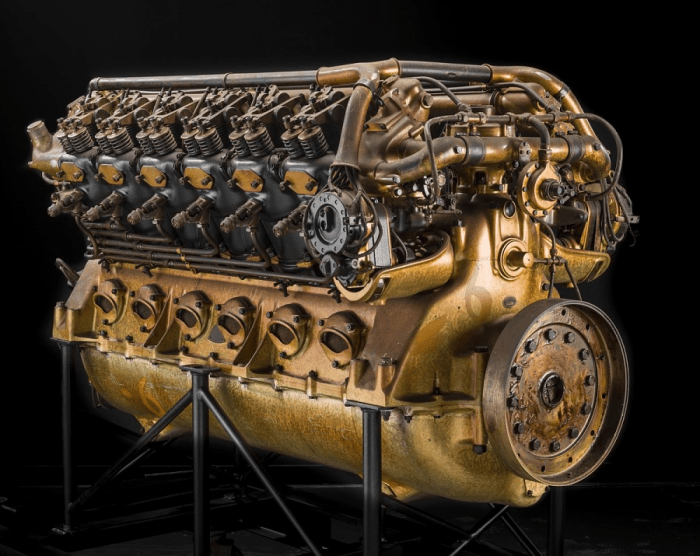

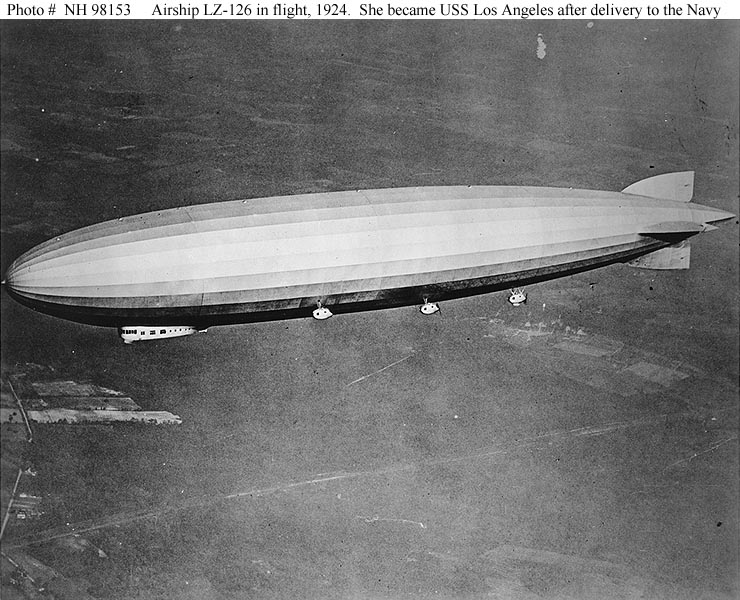

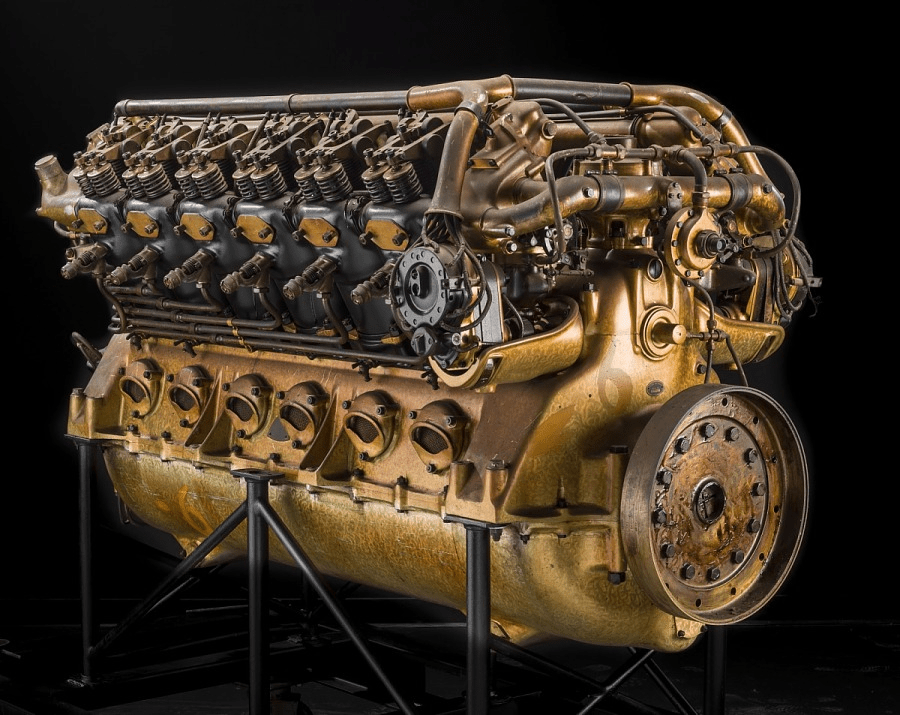

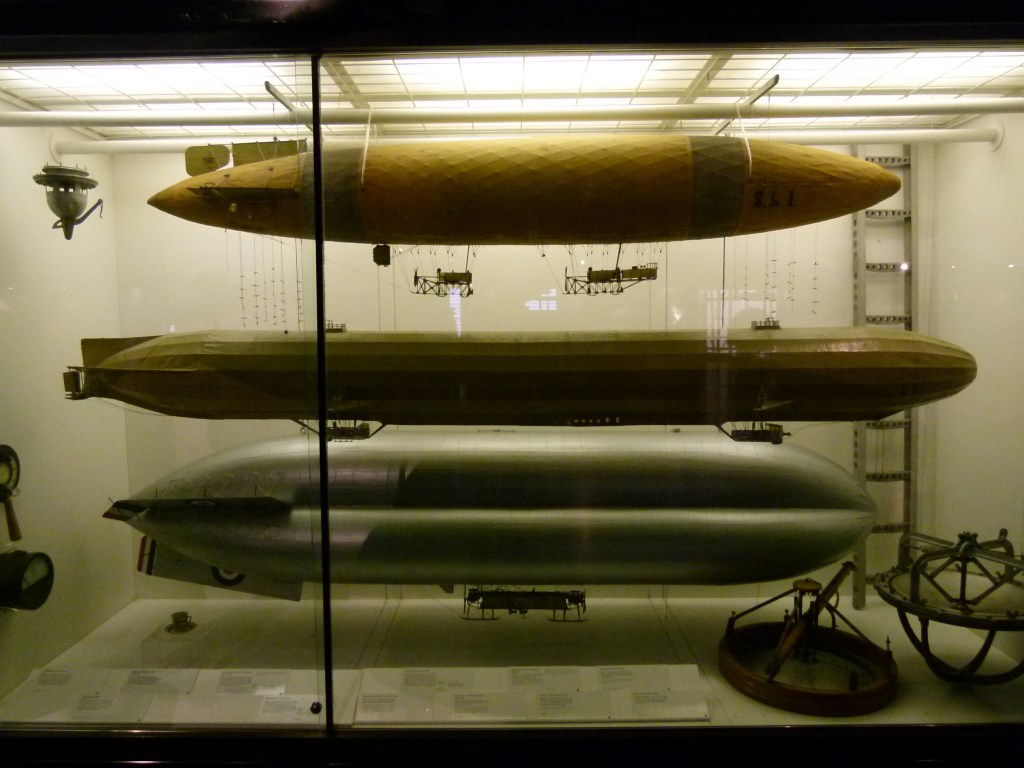

Maybach VL-2, V-12 Engine vs. AM Racing AMR Dual Stack 250-90 AC Motor

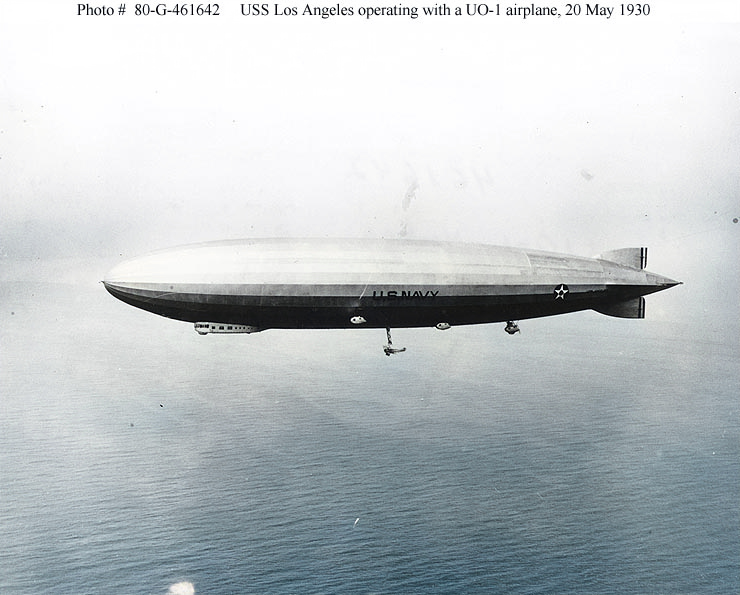

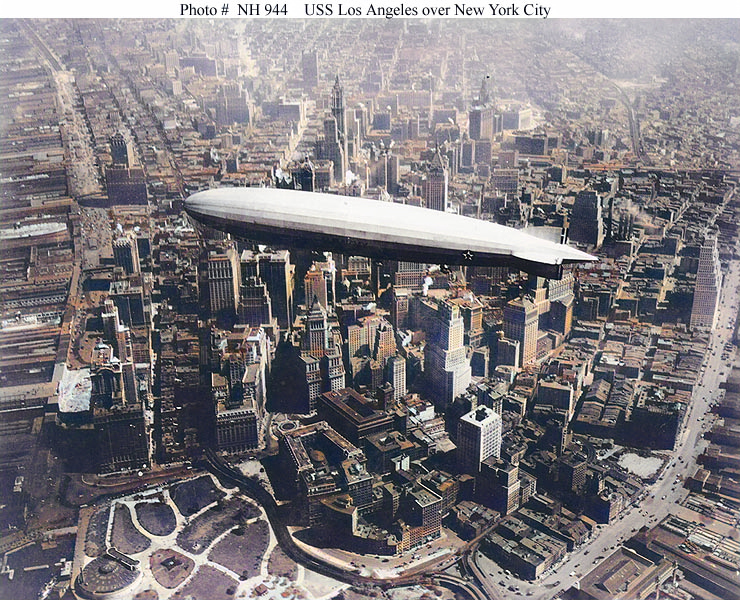

We had a chat with Andrew on what sort of motors were powering airships in a past, how much power they had and how that would look today so we did a tiny research.

Let me introduce the Maybach VL-2, V-12 Engine first.

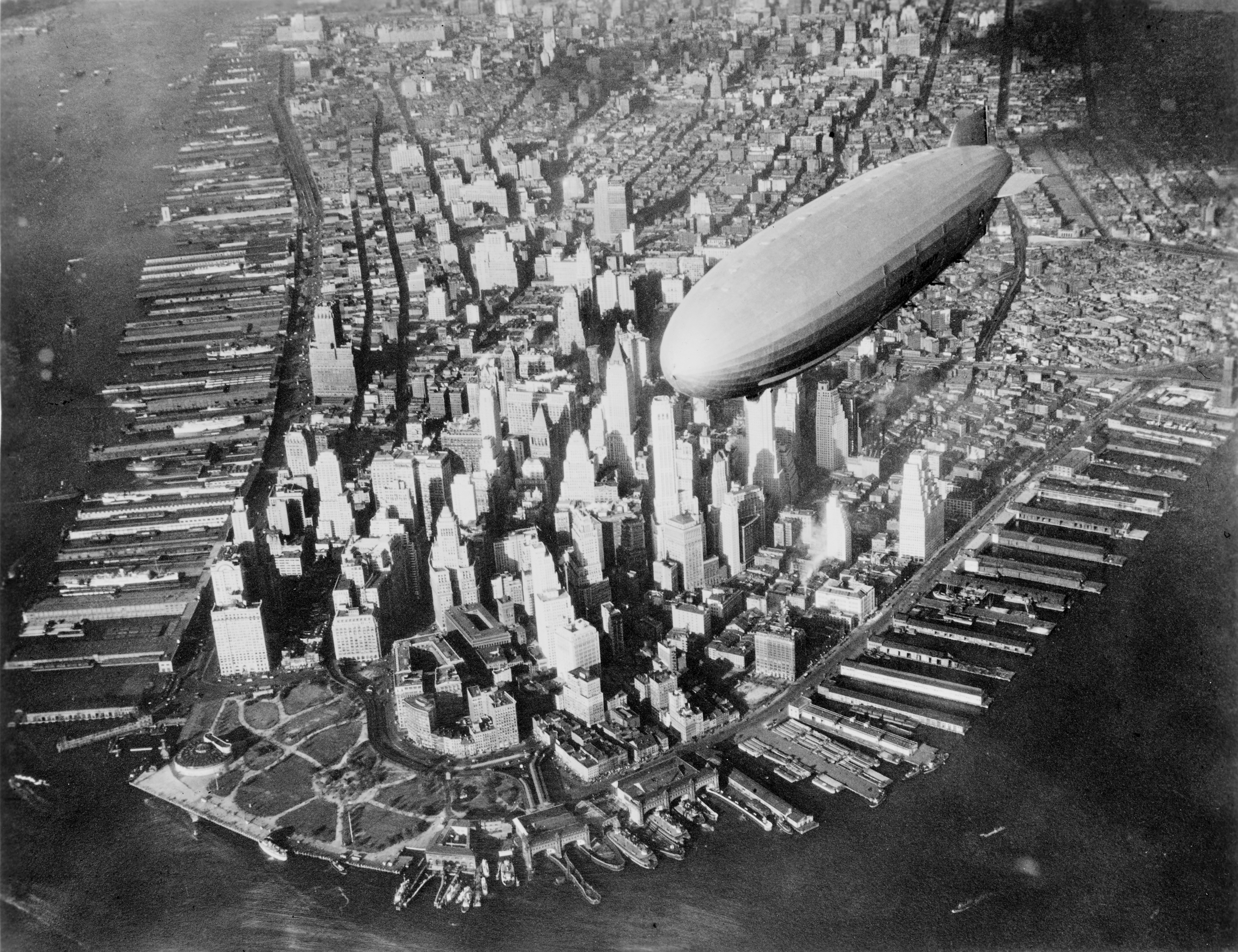

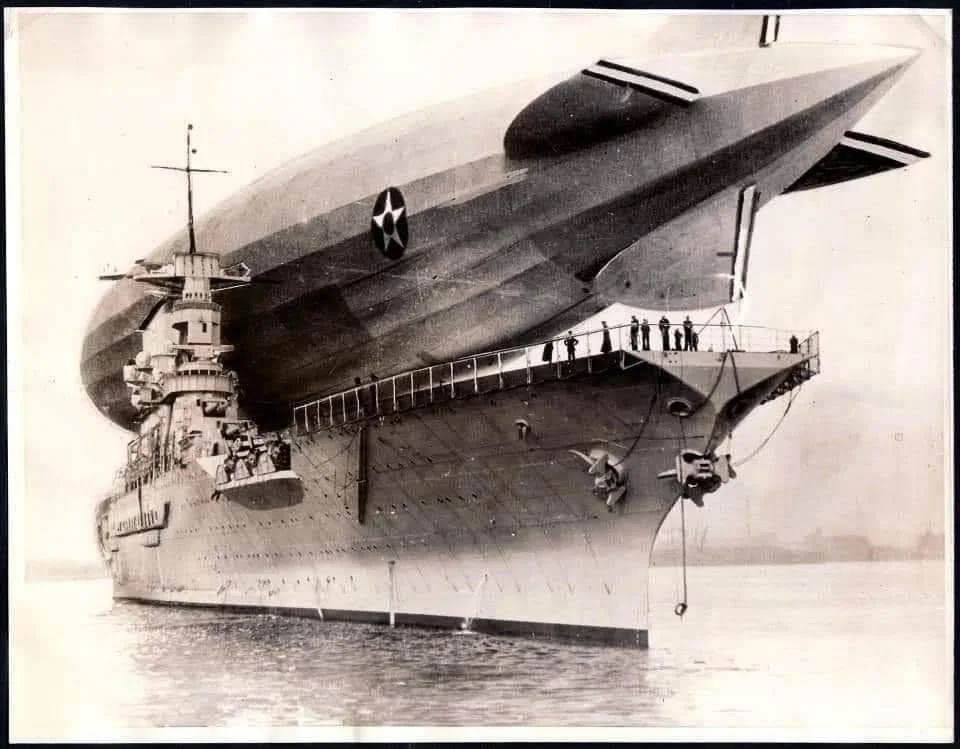

This engine powered the largest airships ever made German Graf Zeppelin, U.S. Akron, and Macon between years 1928 and 1934. It was reciprocating, 12 cylinders, V-type, fuel injected, water-cooled beast – weighting 2,530 lb (1,148 kg). Its power rating was 425 kW (570 hp) at 1,600 rpm Displacement: 33.3 L (2,029 cu in.).

Namely the LZ 127 Graf Zeppelin was powered by five of these monsters, mounted in individual streamlined nacelles arranged so that each was in an undisturbed airflow. Taking the values from above, it makes a total of 2,125 kW (2,850 hp) power output, while weighting almost 6 tons (5,740 kg)! To give you something to compare this with – our family car weights 2.44 t, so this is two of them … and more.

Now let’s welcome our second contestant – AM Racing AMR Dual Stack 250-90 AC Motor.

This baby dates back to 2014 and it is a Liquid Cooled, Permanent Magnet – Remy motor weighting incredible 180 lb (82 kg). It comes with rated torque: 560 lb Ft Peak (w/150 kW controller) and rated power 420 HP peak (w/150 kW controller) Max RPM: 10,000.

Let’s do the same maths as per our lovely Maybach above – taking values from above, our Remy motor sort of matches it based on the peak power value advertised so taking 5 of them as per the Zeppelin configuration. Well 5*180 lb -> 900 lb (410 kg)…. this is 10-times less then the same configuration with Maybachs weighting almost 6 tons (5,740 kg)!

Here comes a huge disclaimer that I am well aware that I am here comparing apples with pears, but I still find it amazing that almost a century later we can achieve same power output with magnitude smaller and lighter technology. Same way it is fascinating what sort of miracles were German engineers to achieve that time.

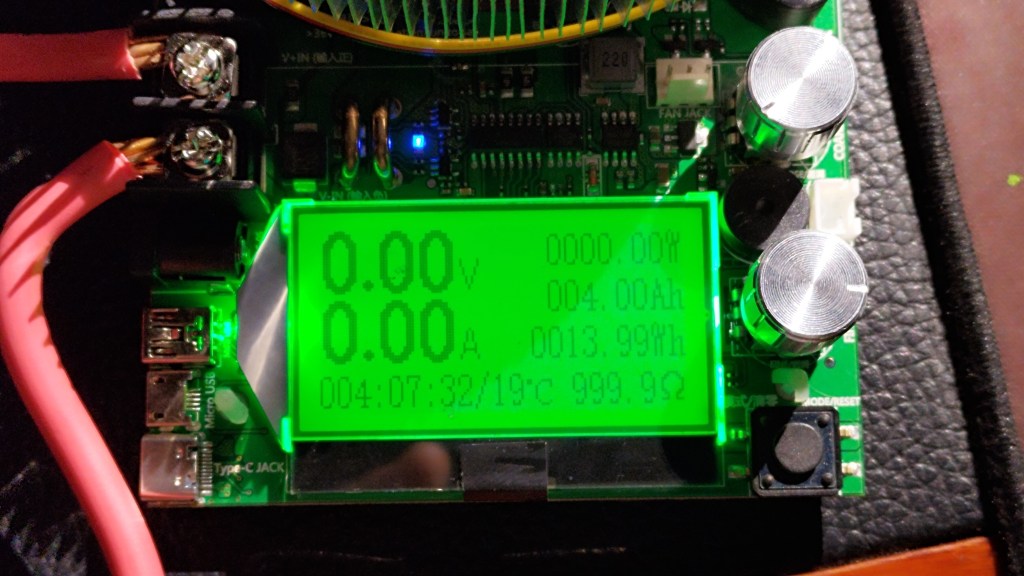

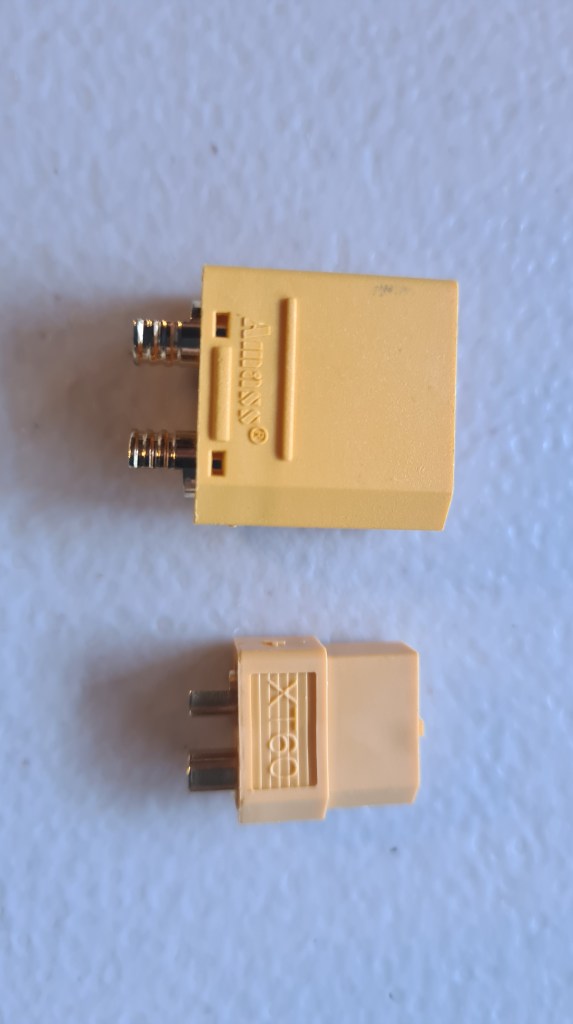

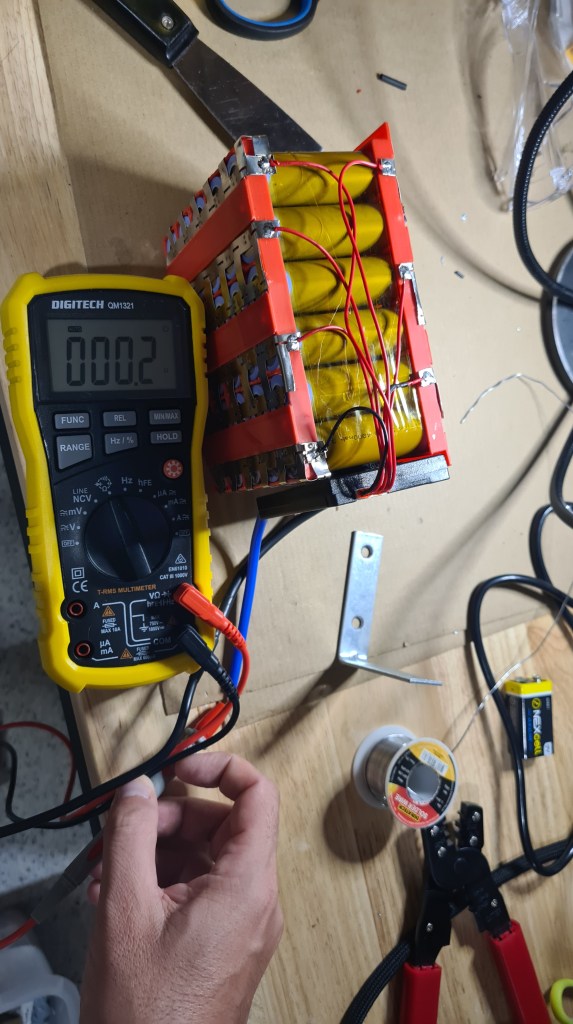

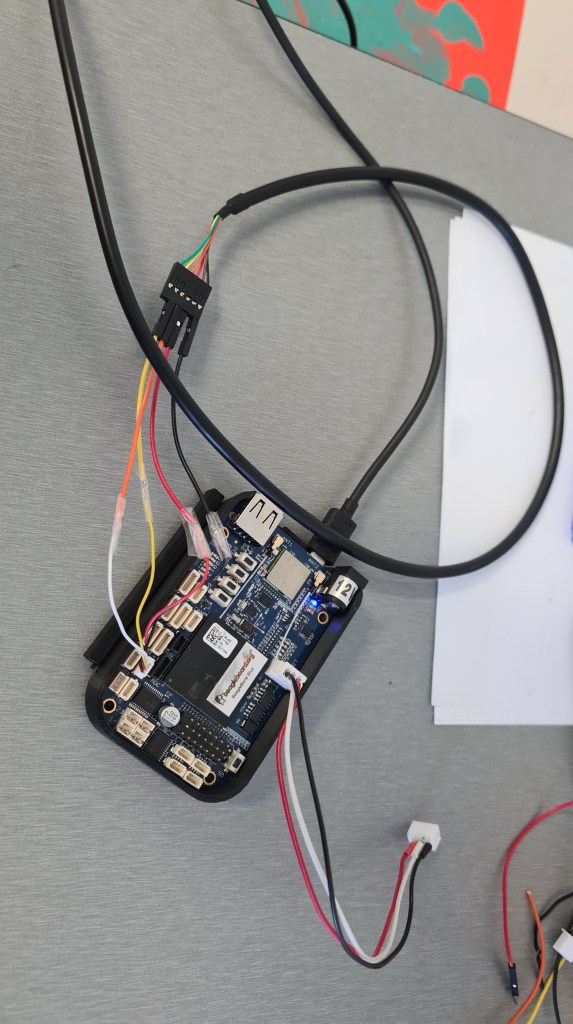

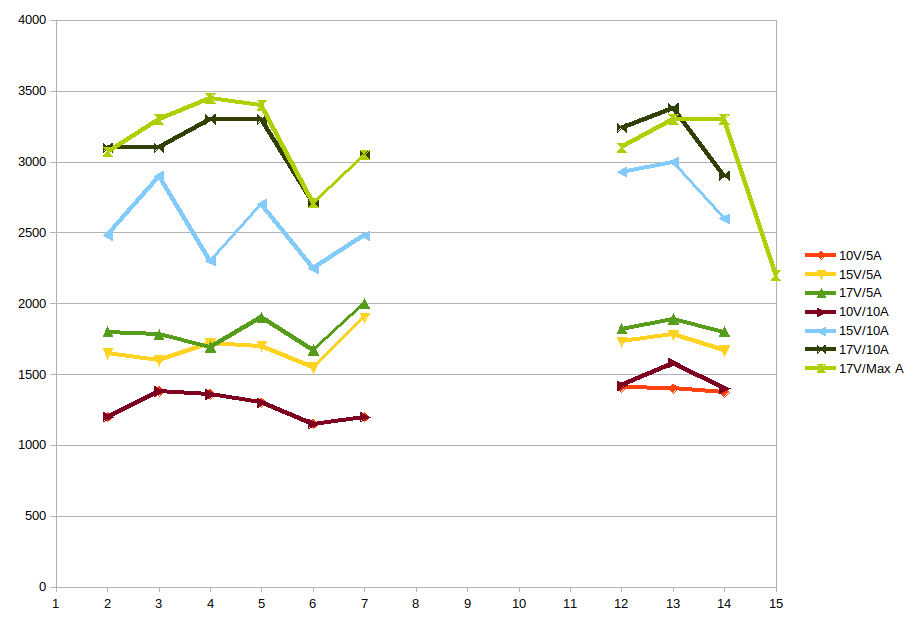

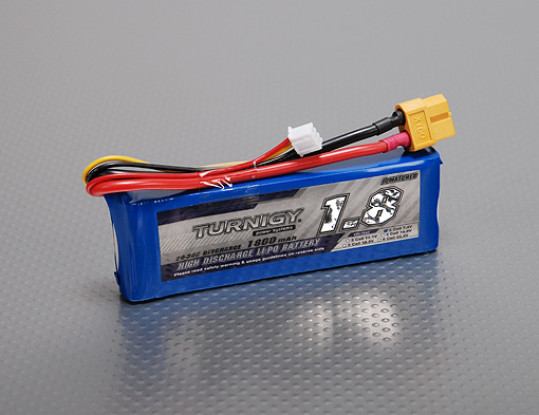

Power management update II

This is a follow up on a previous Power management update article, where I was attempting to reduce number of batteries in our system. Long story short – it didn’t work out as I was hoping for. That DC to DC Step Down Voltage Converter Module I’ve picked wasn’t powerful enough (Max output current 1.5A) to let all servos and ESCs running. Even after doubling it – it wasn’t reliable enough.

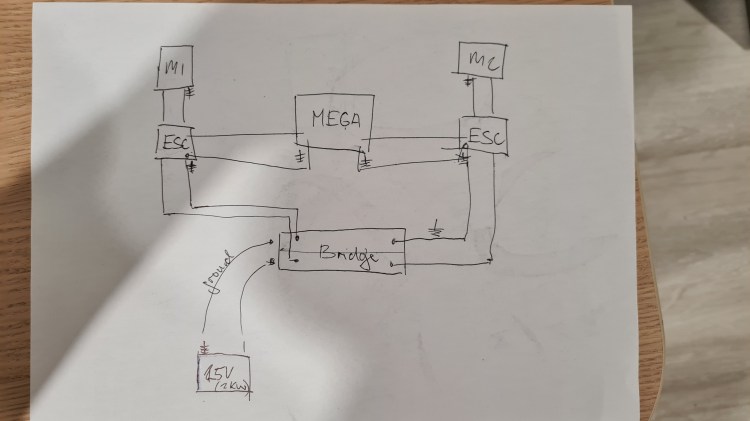

So I’ve ended up buying “24V to 12V 10A DC 2 DC Converter Step Down Daygreen Reliable Quality , Newest Type CE Certificated”

.. and also “Waterproof 12V 24V to 6V 3A 18W 5A 30W DC DC Step Down Voltage Converter 12Vdc 24Vdc to 6Vdc Buck Car Charger Power Module”

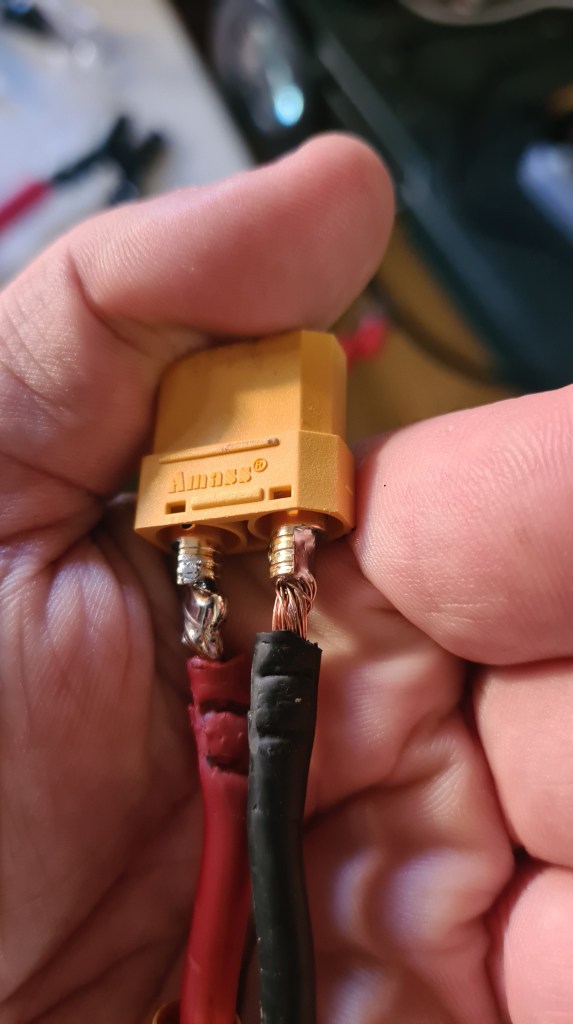

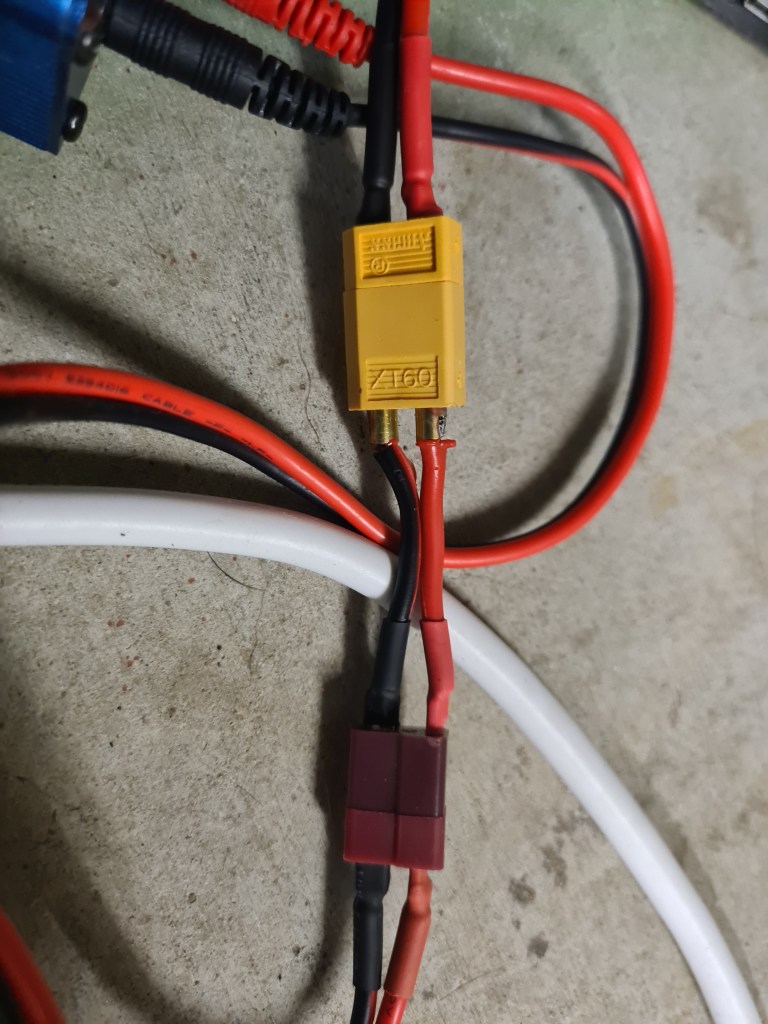

Both arrived in a good condition and some easy wiring was needed.

- The shared XT60 connector goes into our power bridge (24V / 70A input)

- 5mm jack goes into Arduino Mega (12V / 10A output)

- loose wires are for the sensor bridge (6V / 5A)

I did some minor testing to see that voltages are where they belong.

All seems to be happy! So once again – all ready for Sebi to give it a go! 🙂

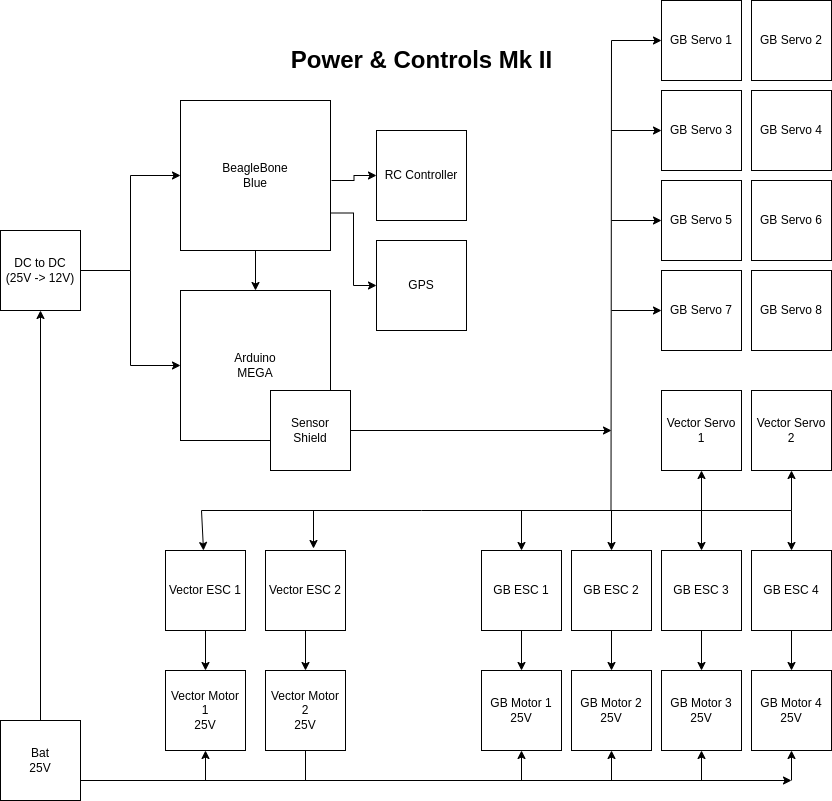

Update I: Adding the latest power distribution & controls diagram

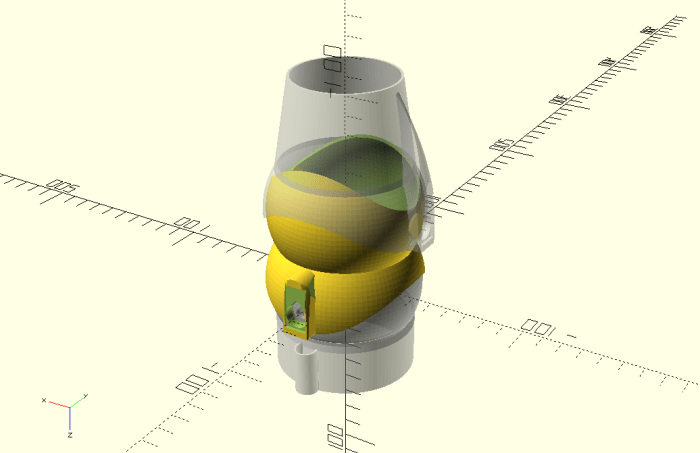

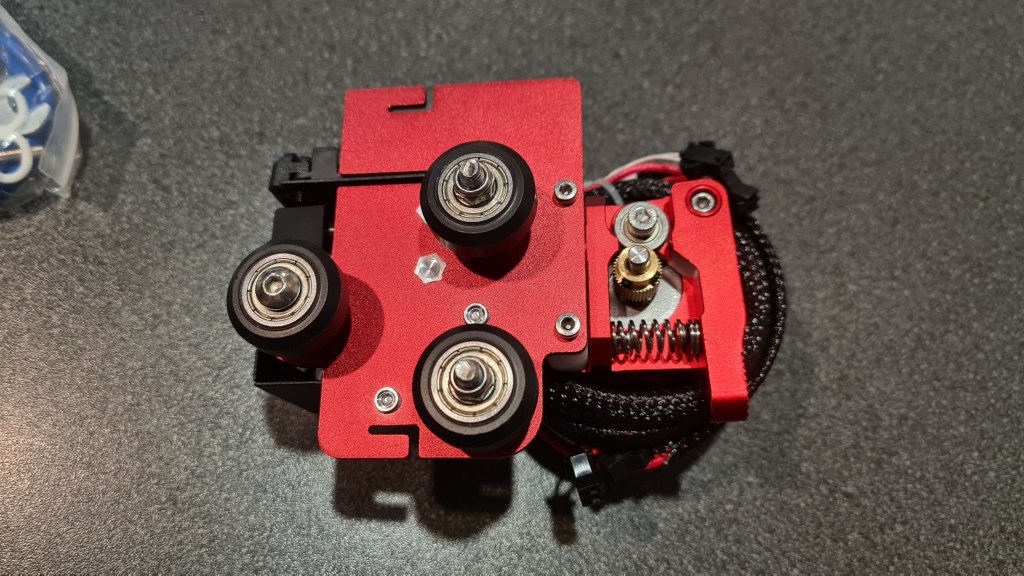

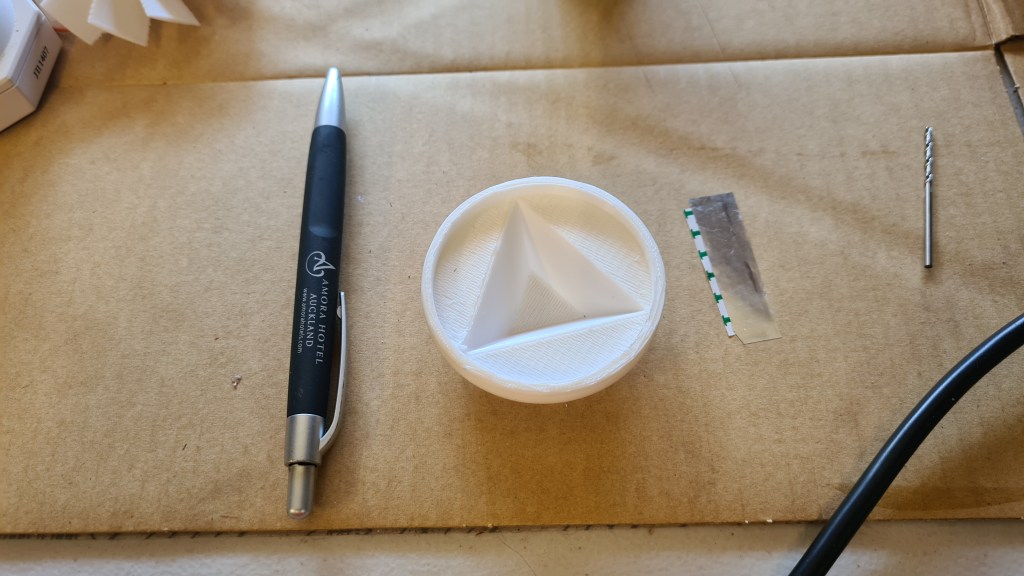

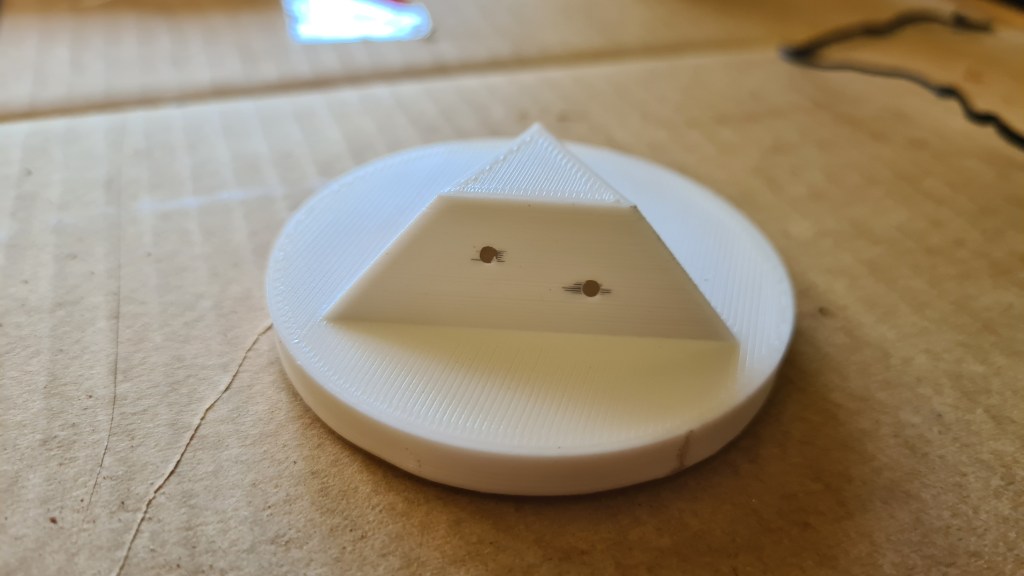

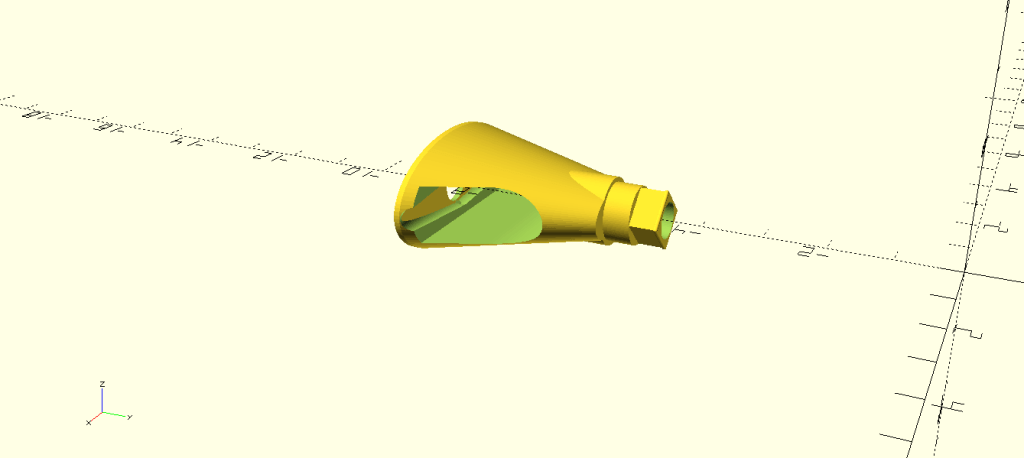

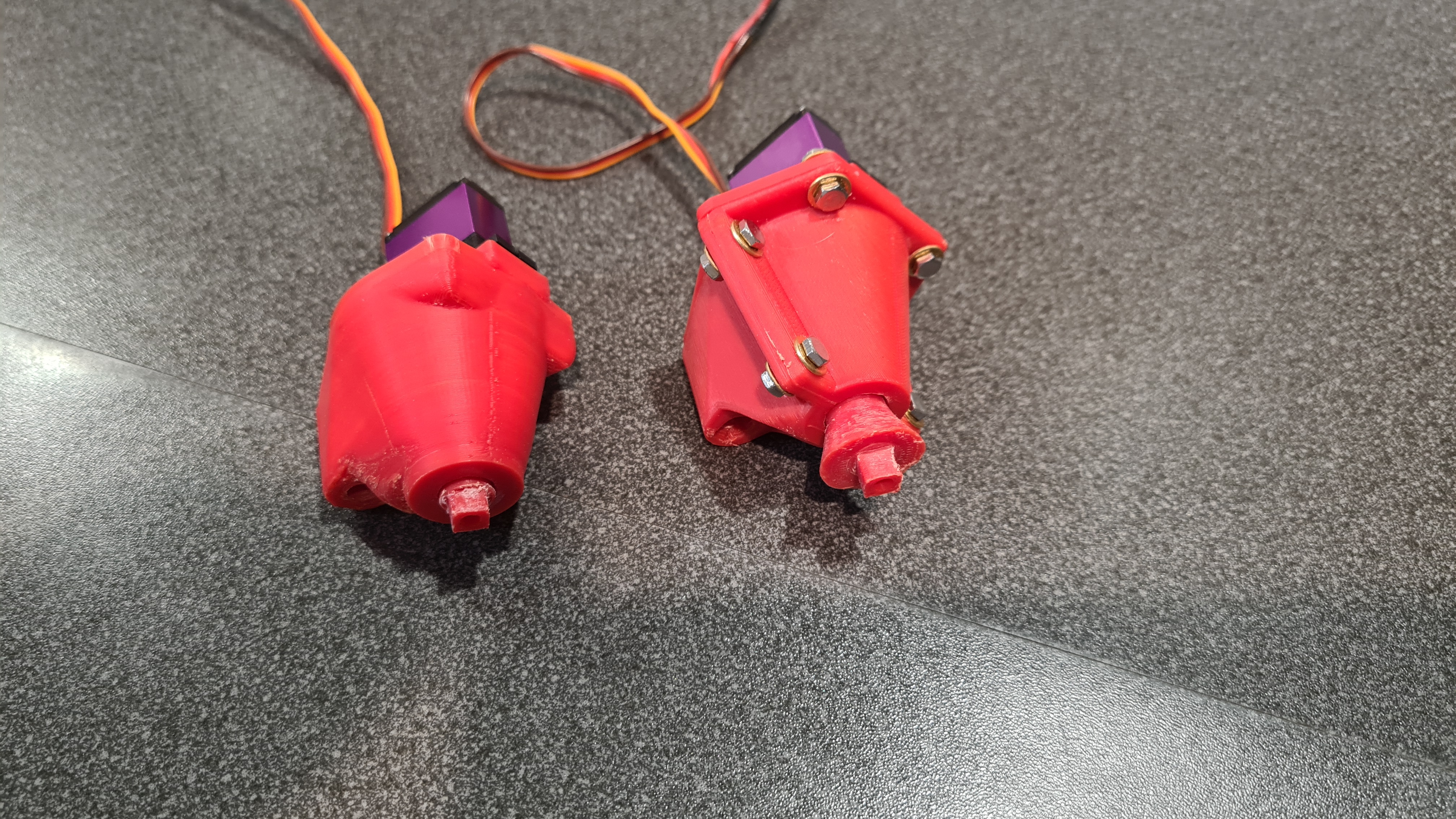

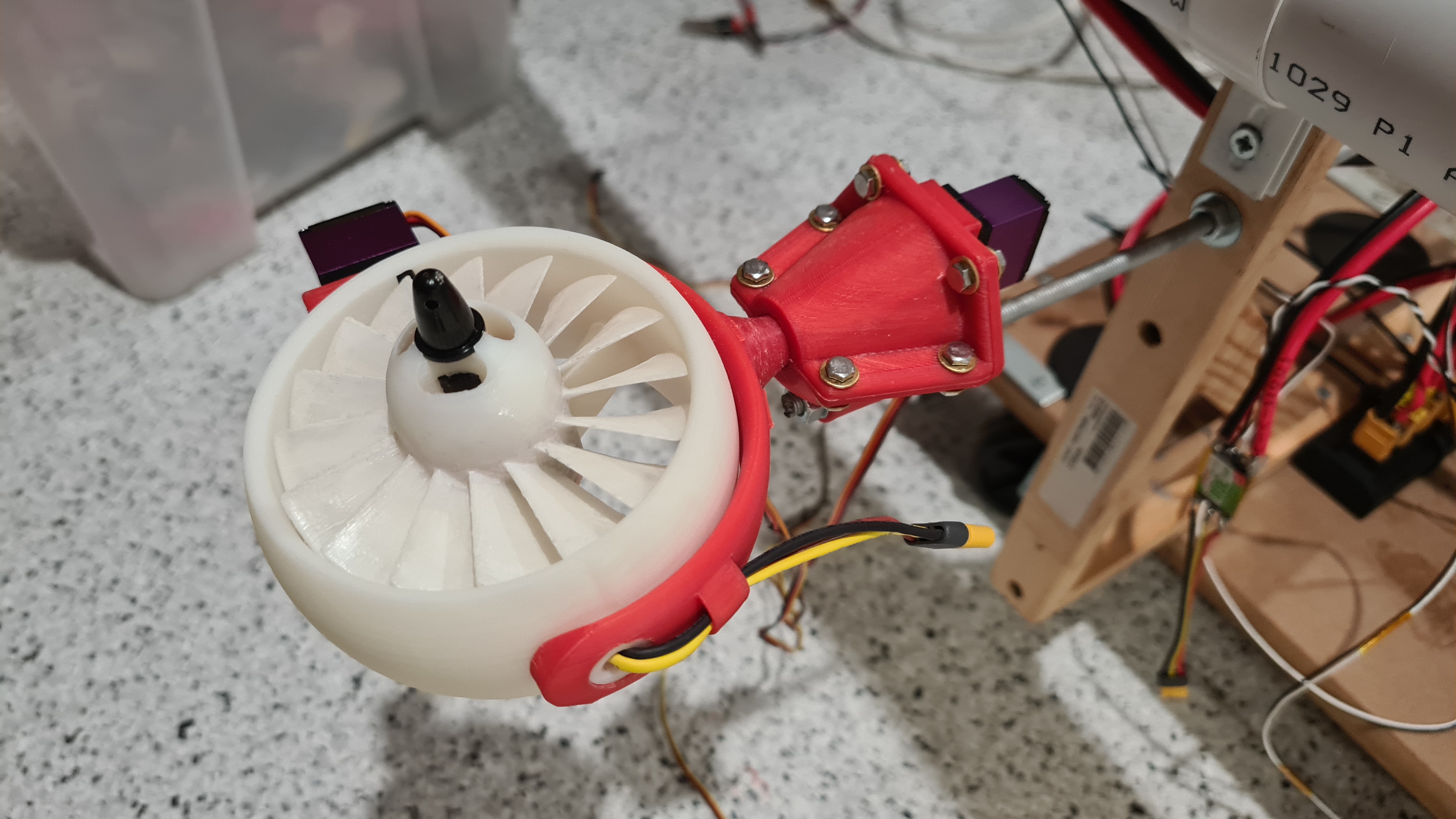

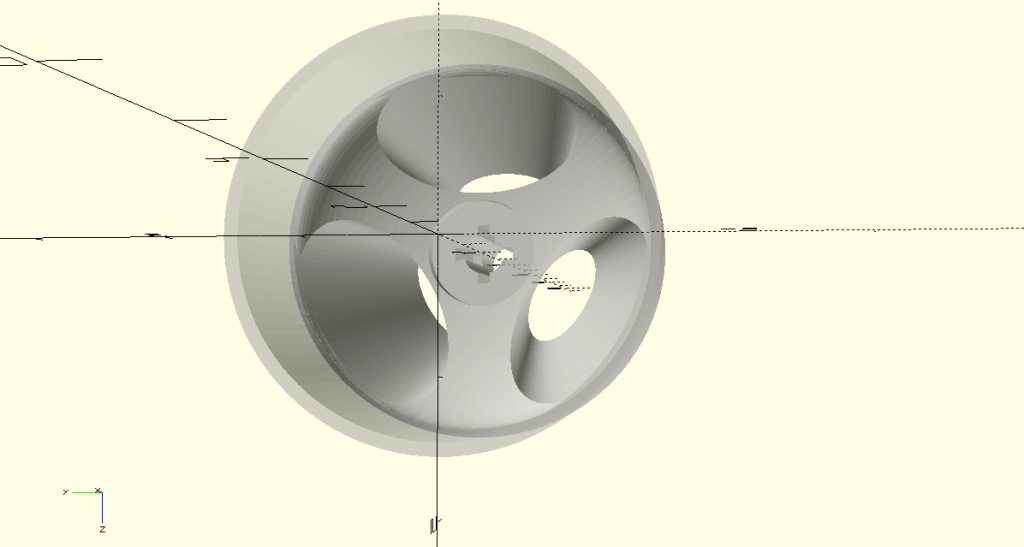

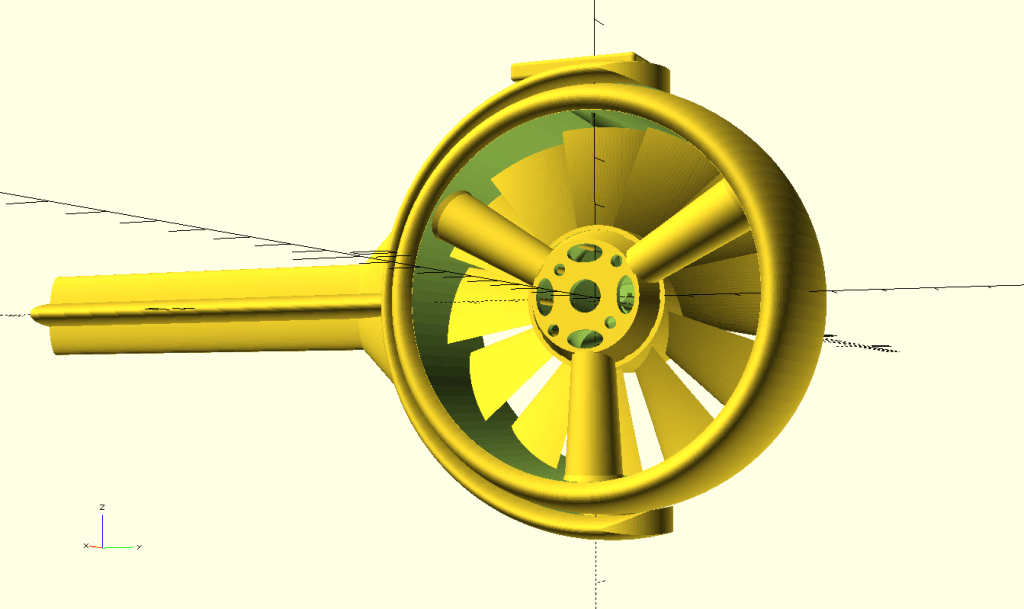

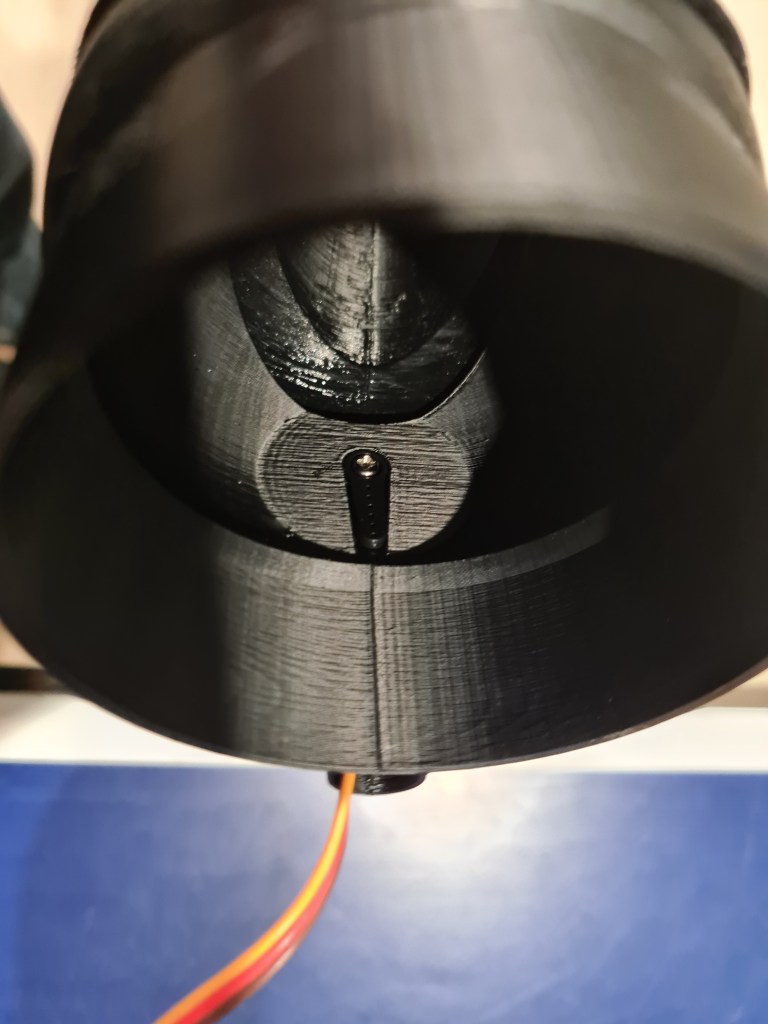

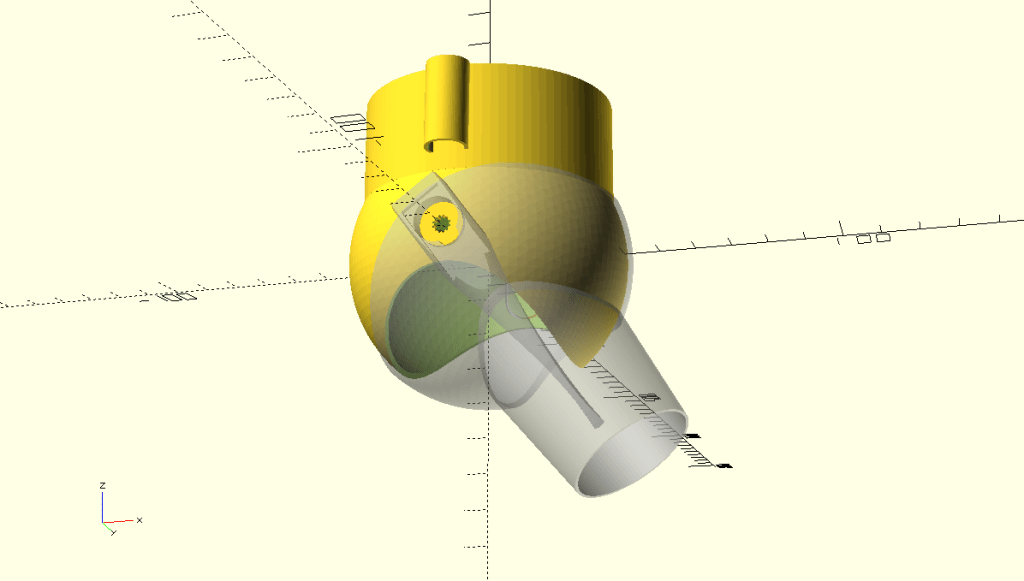

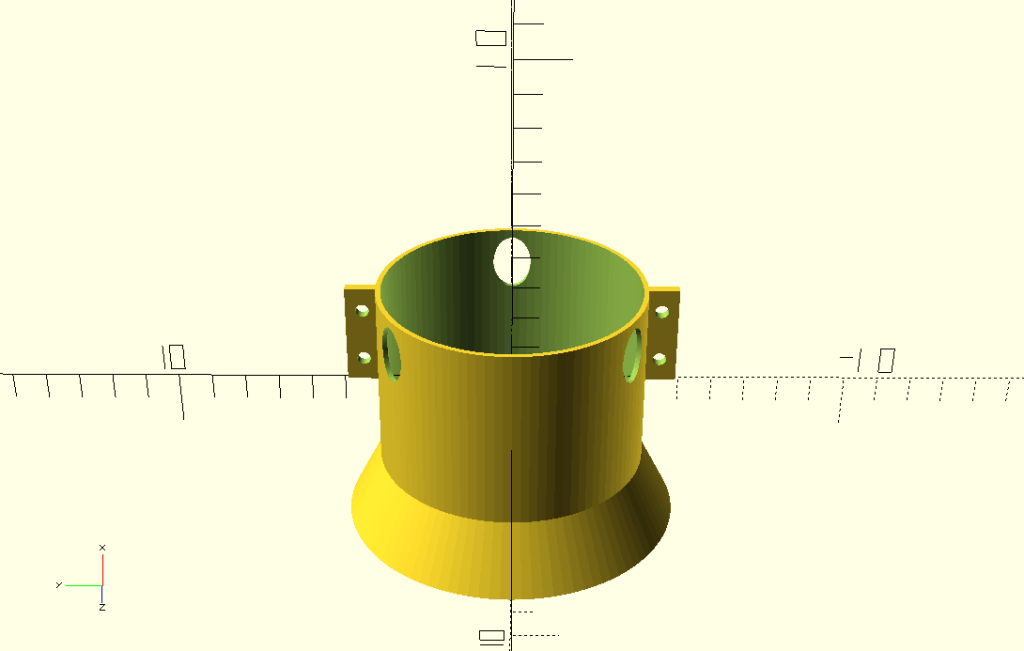

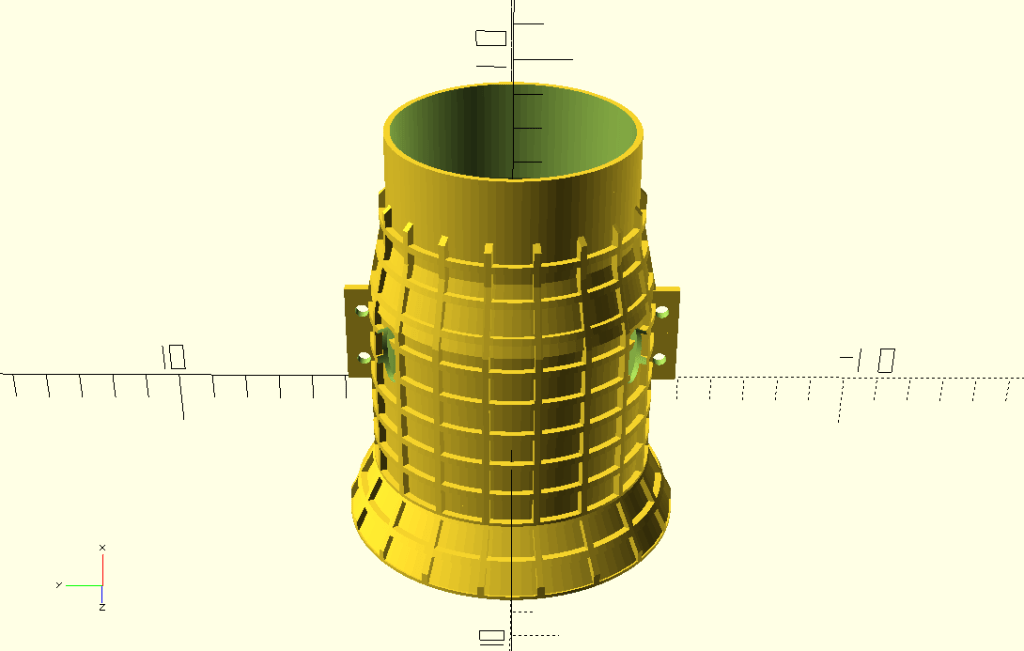

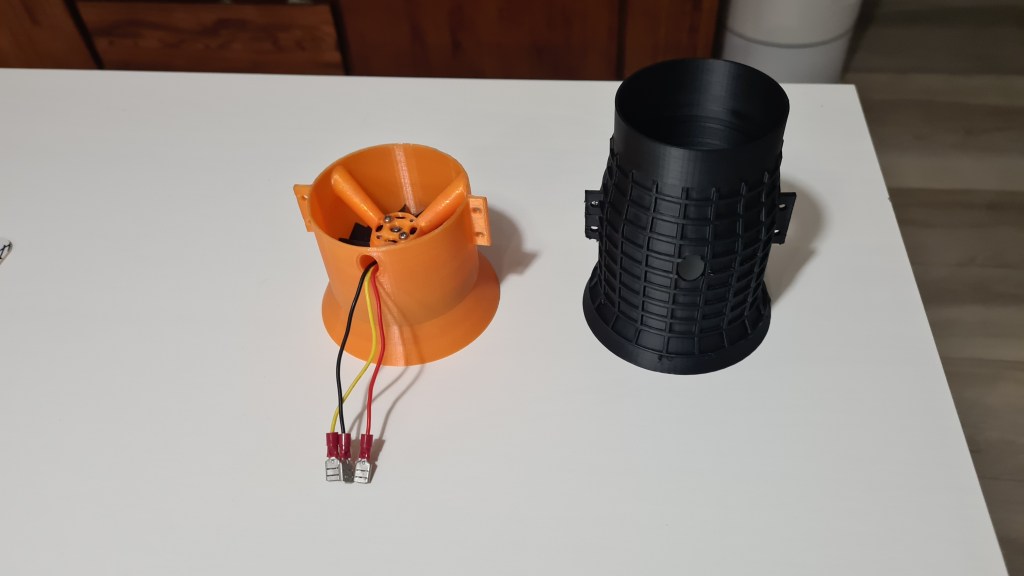

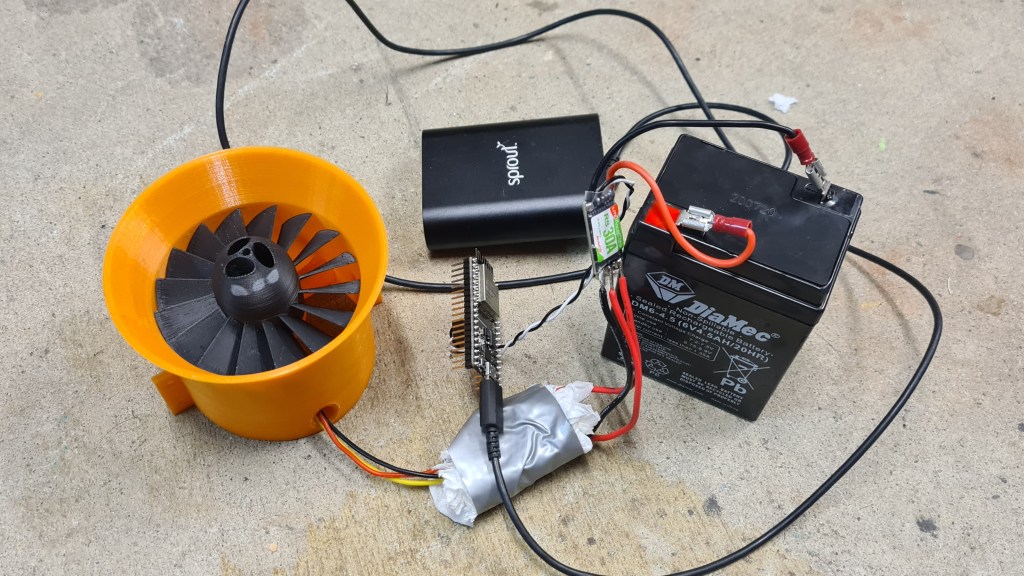

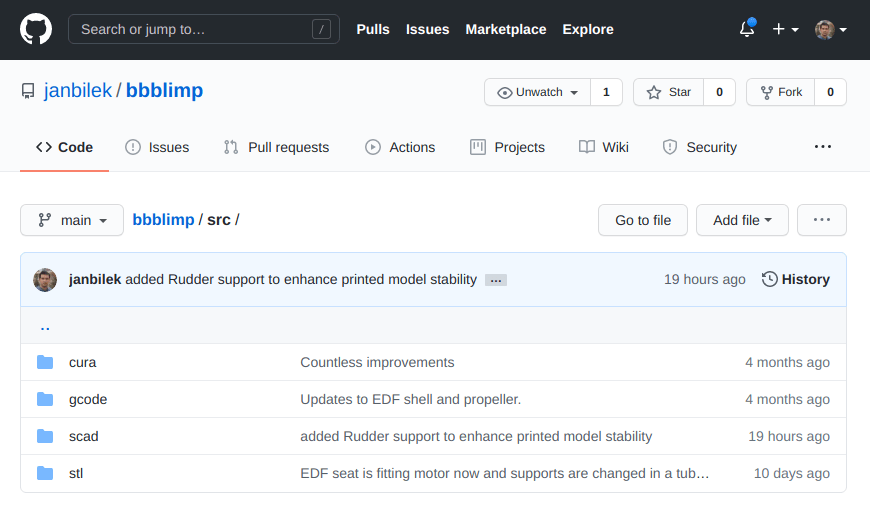

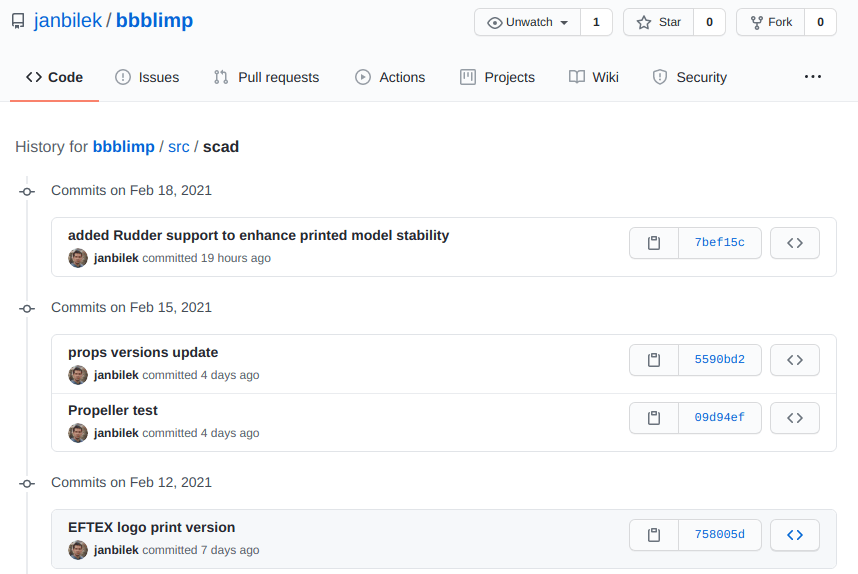

Vectoring Thruster 3D

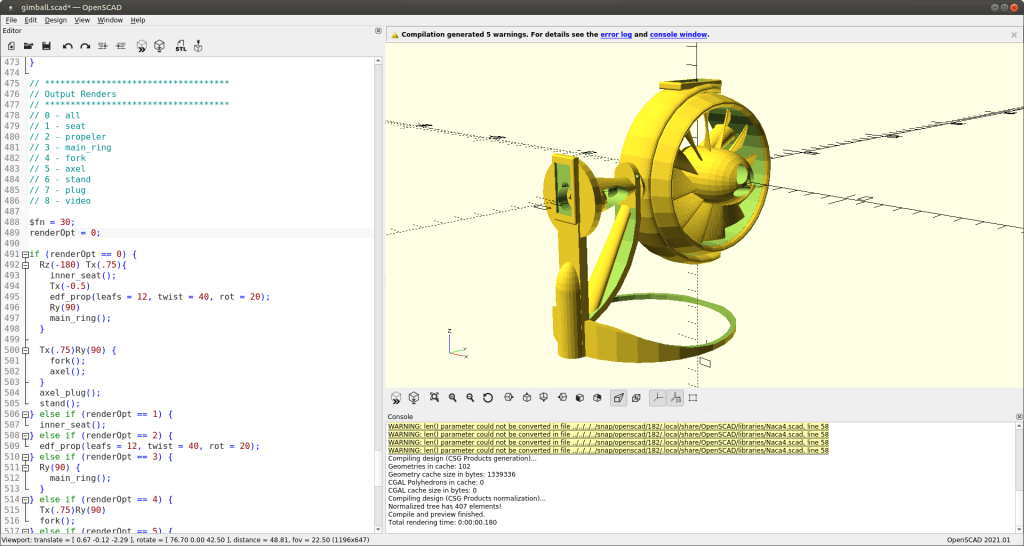

I needed Sebi to design something for our friend (I’ll probably make another post about it when having that project finished) and he did it in the OpenSCAD. This came bit as a surprise because Sebi’s been using some different app, which I don’t know … and I am lazy to learn.

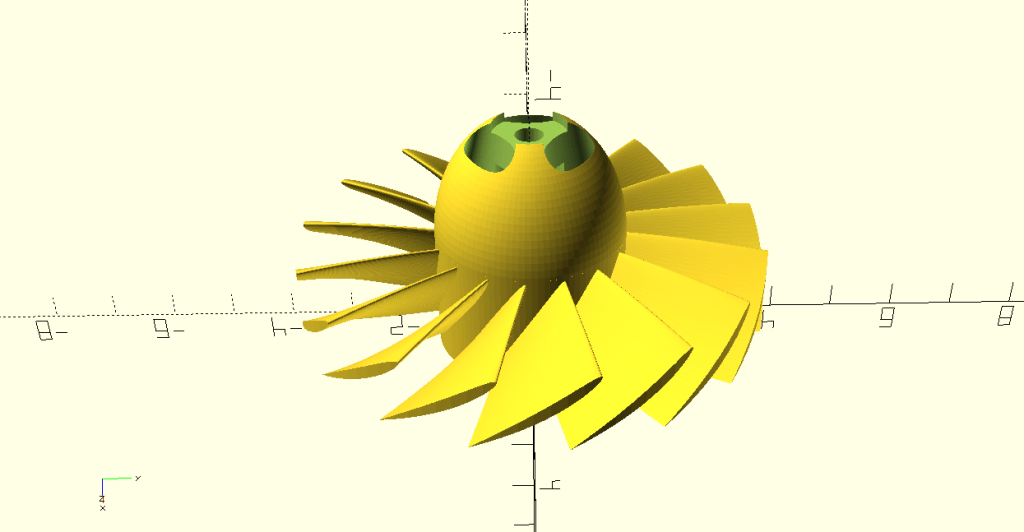

Seeing how well he did, I’ve instantly recalled that there are couple things I would still like to improve on our blimp! I’ve recalled that our vectored thrusters ended up just 2D (a rudder), where I planned to get those 3D when having some spare time.

The plan was easy – reuse maximum of what we already have – which is doing well in 2D and insert a new piece between the nozzle and and the vector mount which will be 90o twisted to allow the nozzle to serve as its horizontal stabilisers – elevators.

It worked out perfectly.

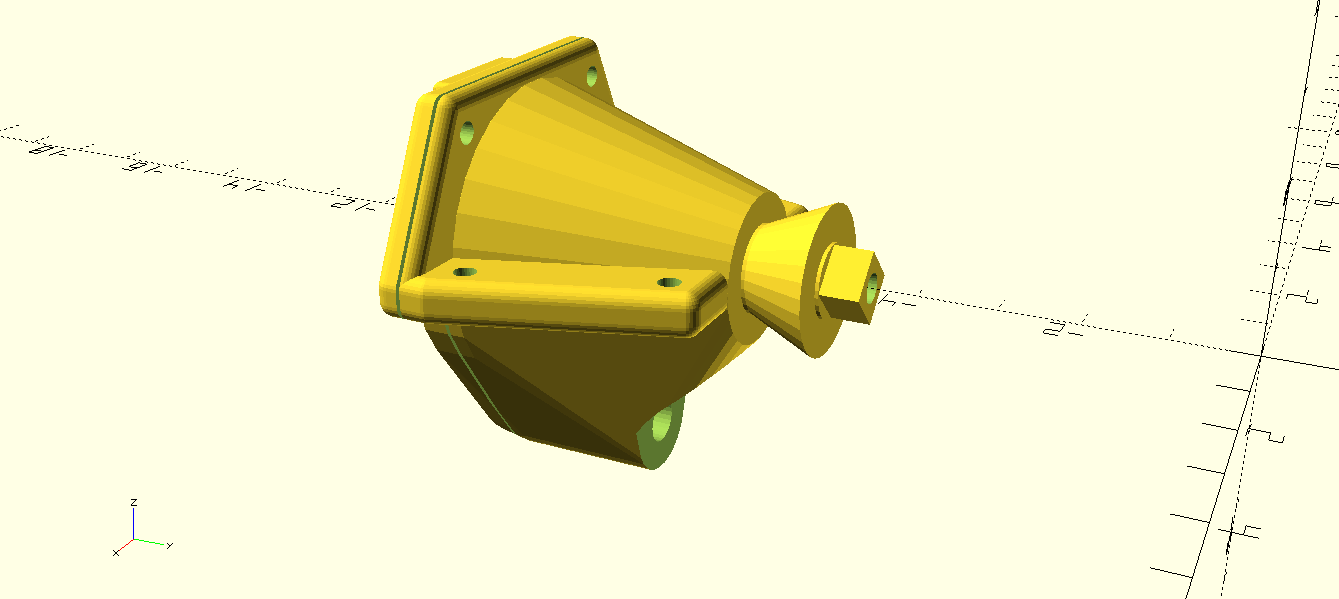

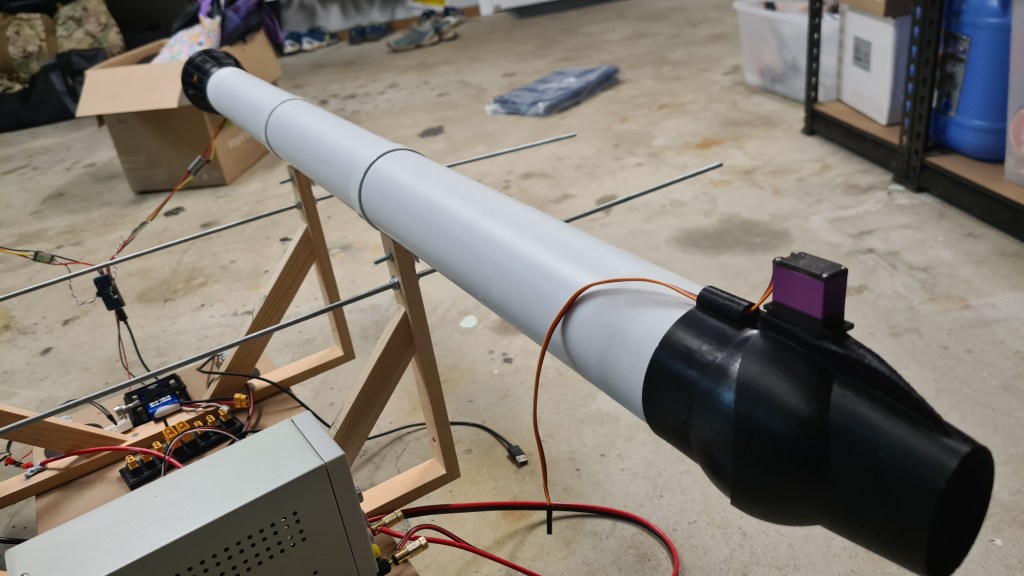

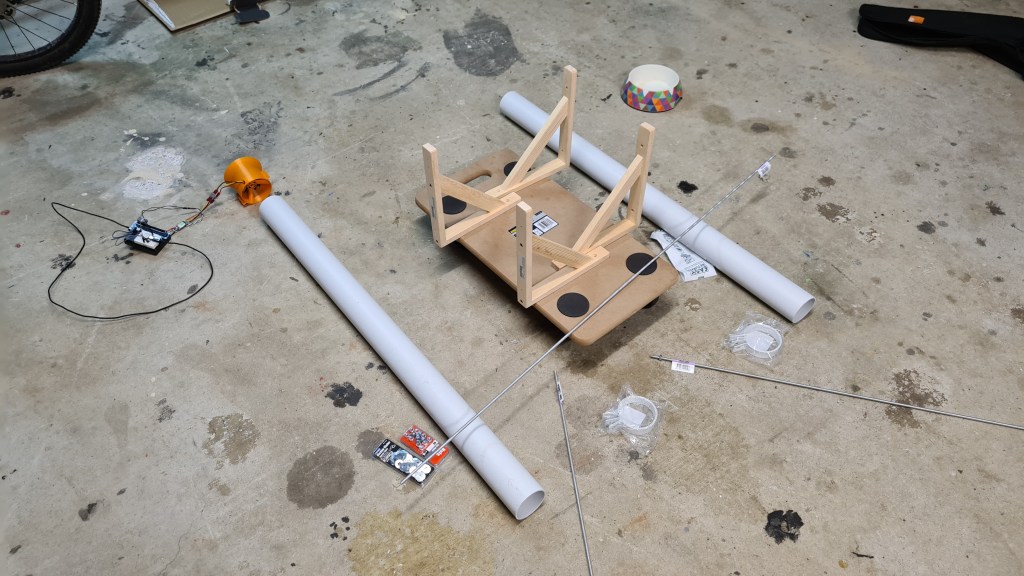

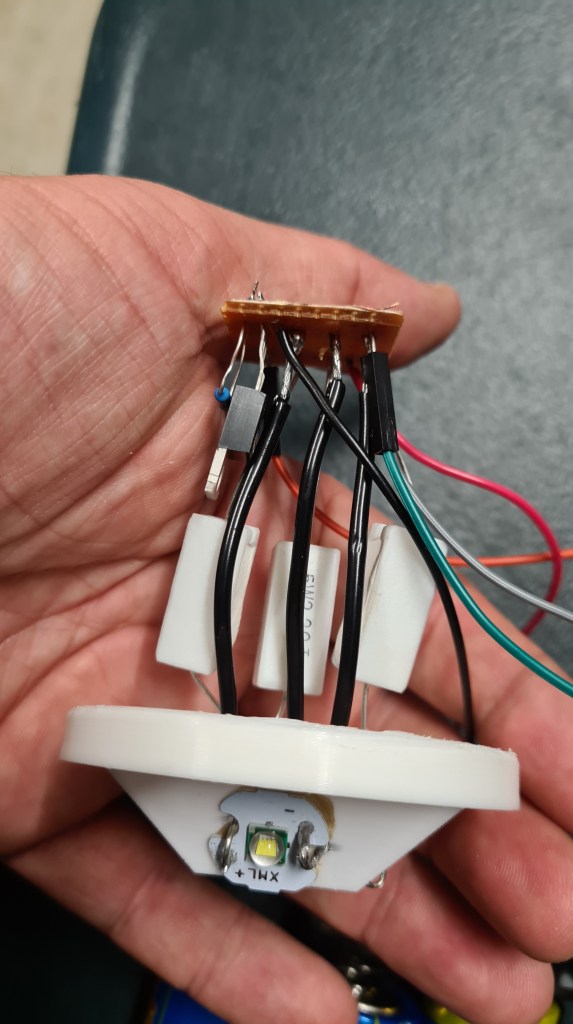

Next stage was to slice it and send it to printer and in couple hours we’ve ended up with a quite interesting setup.

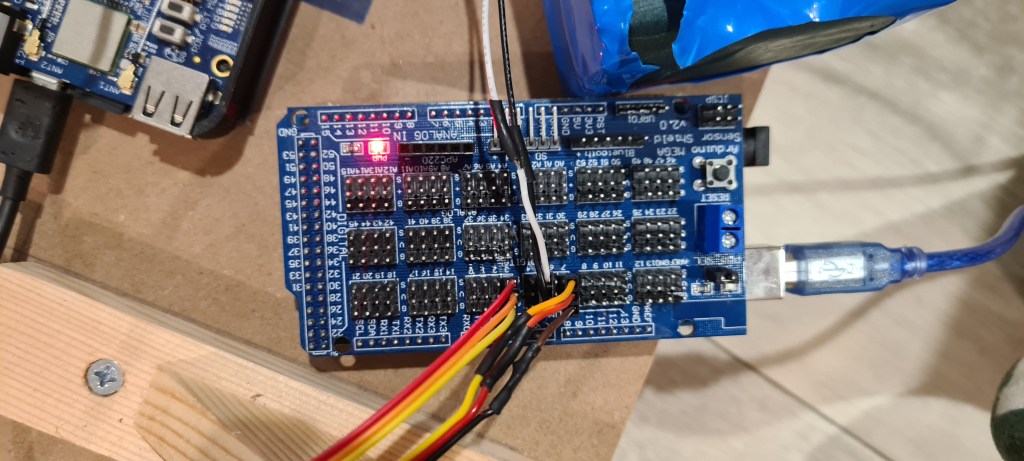

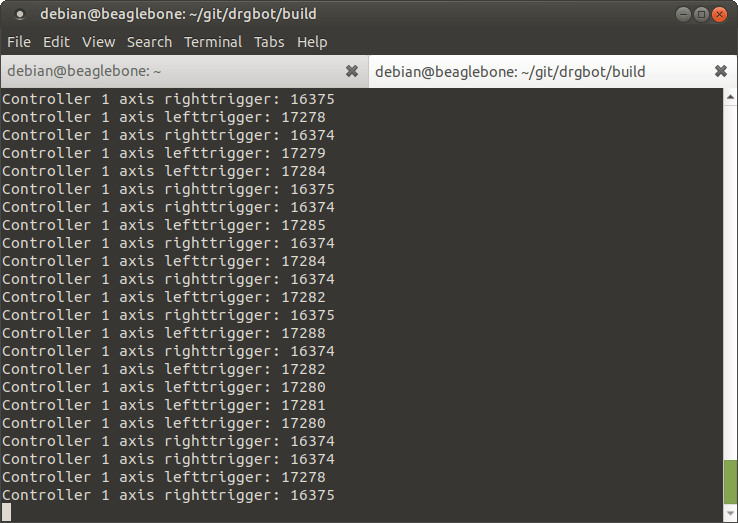

I mounted both servos and Sebi did all the wiring, using one of his spare Arduino Mega and joystick.

Bit of coding from Sebi.

#include <Arduino.h>

#include <Servo.h>

Servo servoX, servoY;

auto potX = A0;

auto potY = A1;

void setup() {

servoX.attach(2);

servoY.attach(3);

}

void loop() {

servoX.write(map(analogRead(potX), 0, 1023, 45, 135)-10);

servoY.write(map(analogRead(potY), 0, 1023, 45, 135)+5);

delay(20);

}

It actually needed some more “love” to polish all the surfaces properly to make all movements smooth, but it worked out perfectly!

Hope you like it too!

Now we need to prepare a second one, mount those on our blimp and add all the elevator logic in there! 🙂

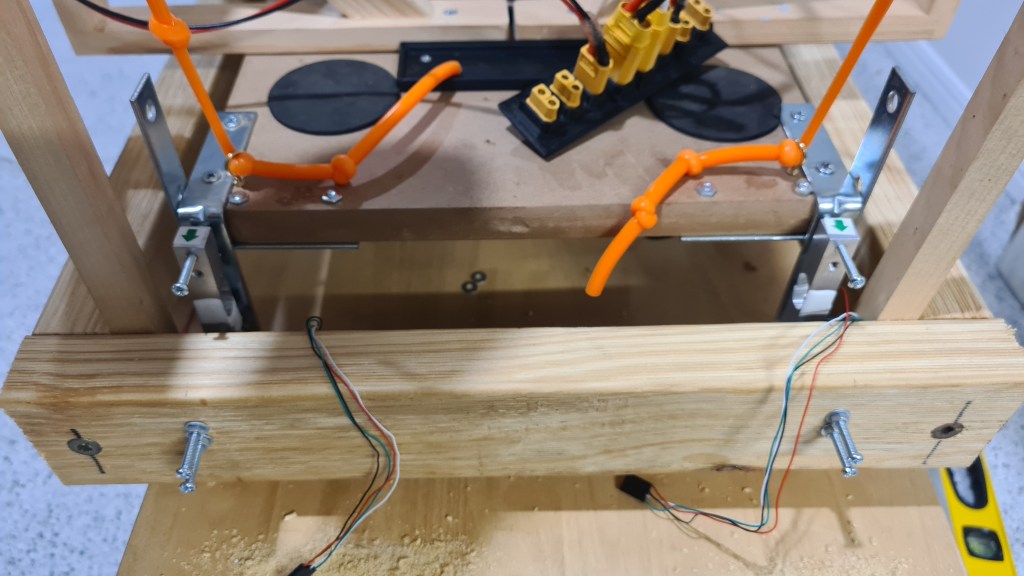

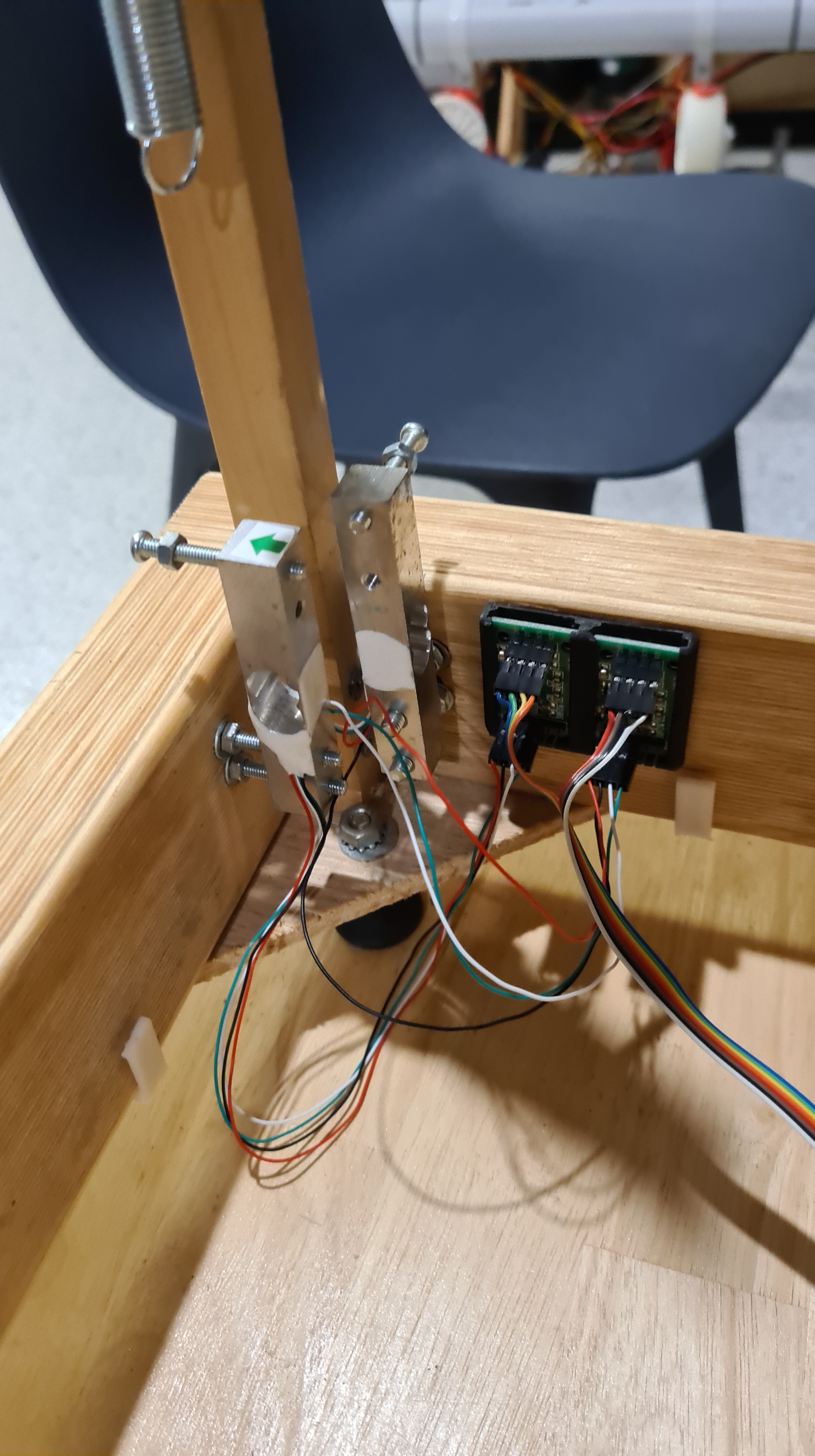

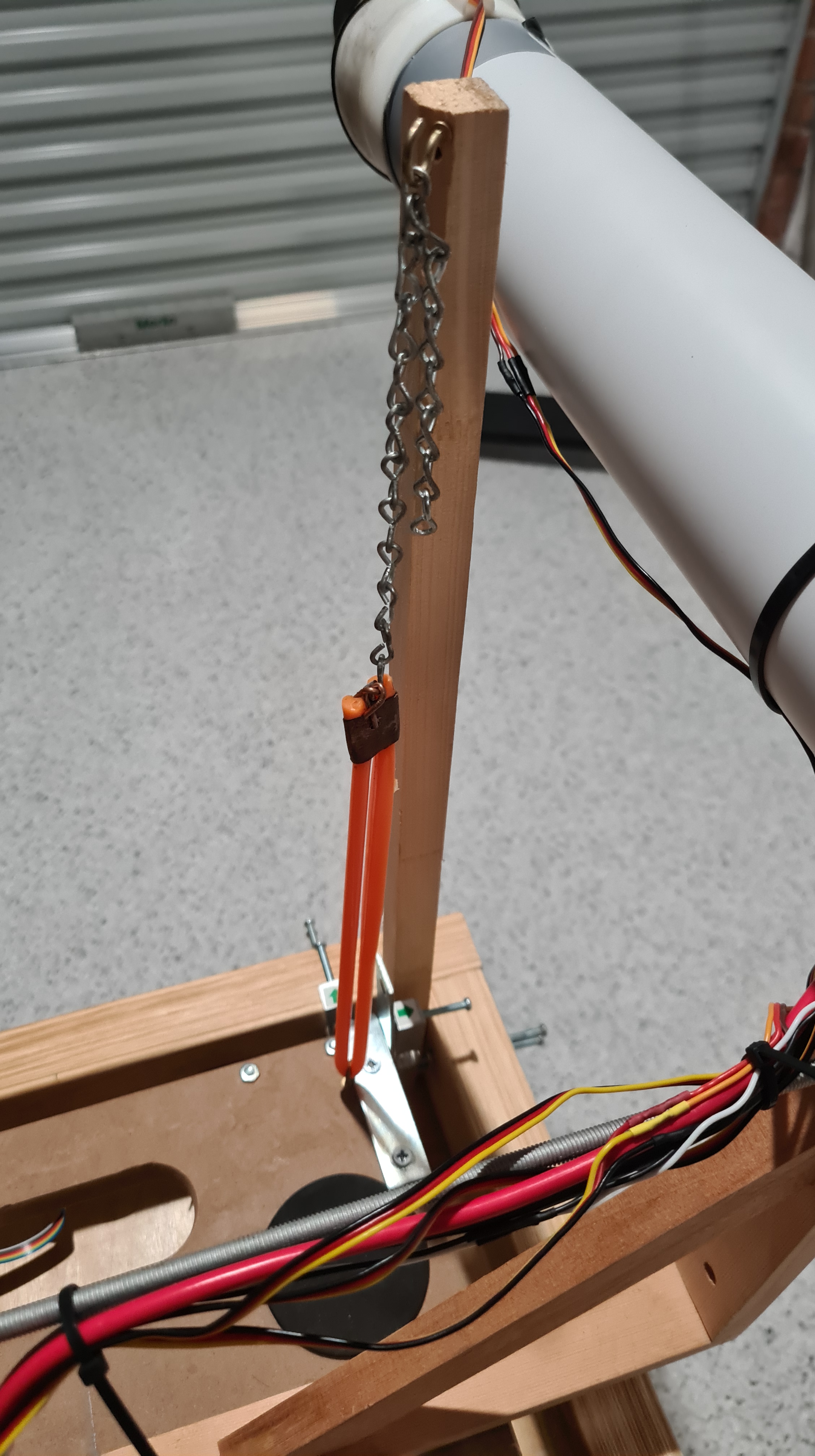

Testing rig upgrade II

This is a follow up on an original article Testing Rig Upgrade, as it just keep going!

Ad the first thing, I have to admit that those rubber-bands were not good enough. I’ve left our model hanging there for a week and they got loose (with a great help of Queensland summer temperatures as well). So they’ve got replaced by springs.

You may wonder why two types … because that C-161 wasn’t strong enough, so I had to upgrade to C163s! All values below are in imperial units – but I suppose it is clear C163 are almost 3-times stronger than those C161s.

Specifications for the Century Spring C-161 Extension Spring

| Part Number: | C-161 |

| Manufacturer: | Century Spring |

| Ajax Part Number: | 50161 |

| Spring Type: | Extension |

| Material: | Galvanized Hard Drawn |

| Wire Size: | 0.035 |

| OD: | 0.437 |

| OAL: | 2.750 |

| Body Length: | 1.875 |

| Max Ext Length: | 5.900 |

| Spring Rate: | 0.5 |

| Max Load: | 3.3 |

VS.

Specifications for the Century Spring C-163 Extension Spring

| Part Number: | C-163 |

| Manufacturer: | Century Spring |

| Ajax Part Number: | 50163 |

| Spring Type: | Extension |

| Material: | Galvanized Hard Drawn |

| Wire Size: | 0.047 |

| OD: | 0.437 |

| OAL: | 3.500 |

| Body Length: | 2.626 |

| Max Ext Length: | 3.600 |

| Spring Rate: | 2 |

| Max Load: | 8.4 |

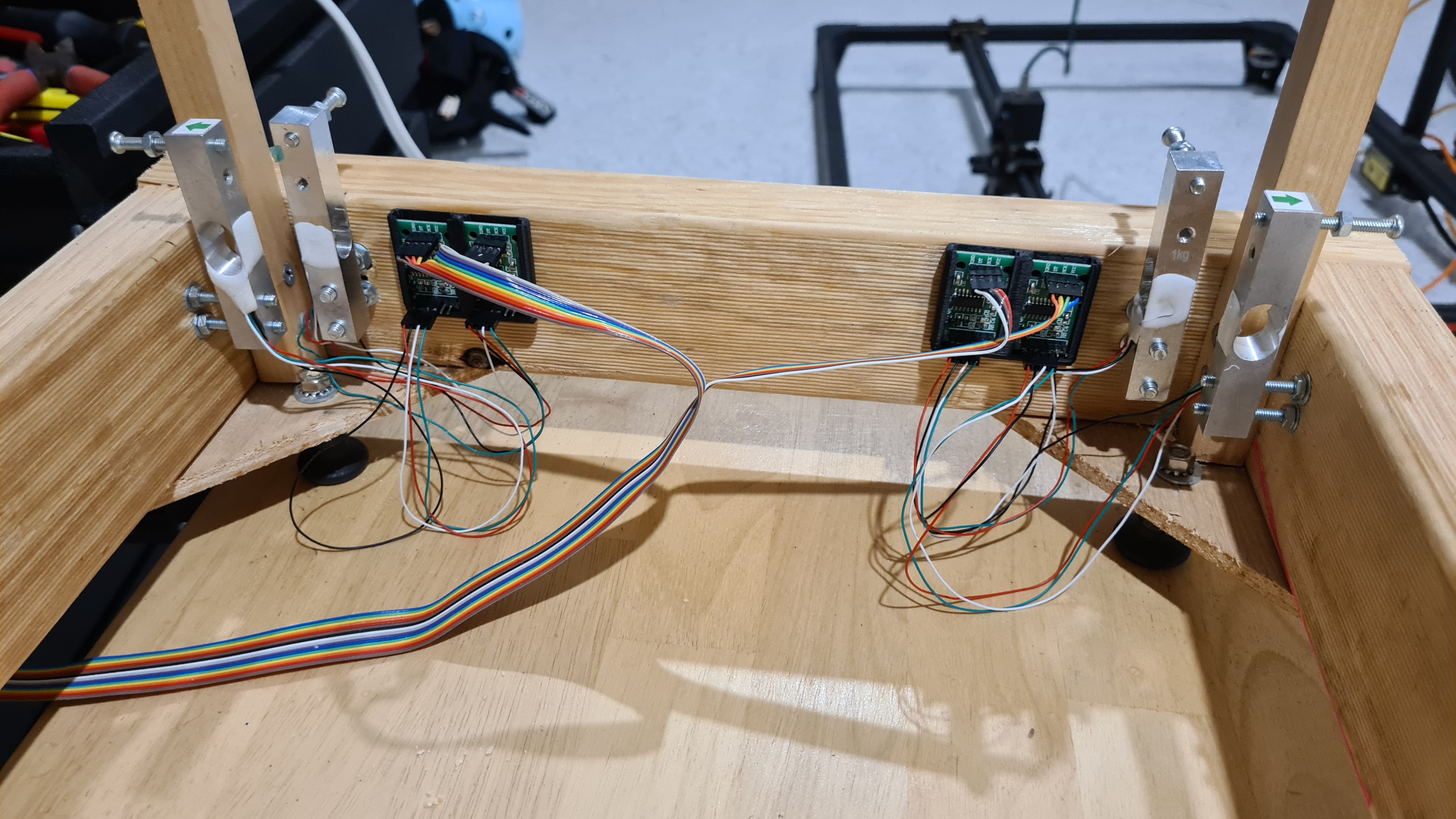

In a next stage I’ve decided to somehow reorganise all the wiring and amplifiers, so they are all not hanging there in the air. That already proven being a bad idea as I’ve damaged couple of those cells in a irreparable way.

The first was a set of load-cells clamps.

Their design was quite trivial.

module pcb_cutout(z) {

T(z,0,2)

cube([21, 2.3, 39], center=true);

//space for pins etc.

T(z,3,2)

cube([18, 12, 37], center=true);

//slide for a chip on a side

T(z+9.3,1,2)

cylinder(39, d=3, $fn=3, center=true);

}

D() {

union() {

//pbc + meat

Ty(-1)

minkowski() {

cube([45.2, 3, 36], center= true);

sphere(2);

}

}

//pbc cutout

pcb_cutout(-12);

pcb_cutout( 12);

//holes

hole_size = 3;

T(12, 0, 1)Rx(90)

cylinder(15,d = hole_size, center = true);

T(-12, 0, 1)Rx(90)

cylinder(15,d = hole_size, center = true);

}

And they come up nicely.

Well, rainbow data cables needed some clamping as well. I’ve printed a set of very simple L-shapes to hold those well.

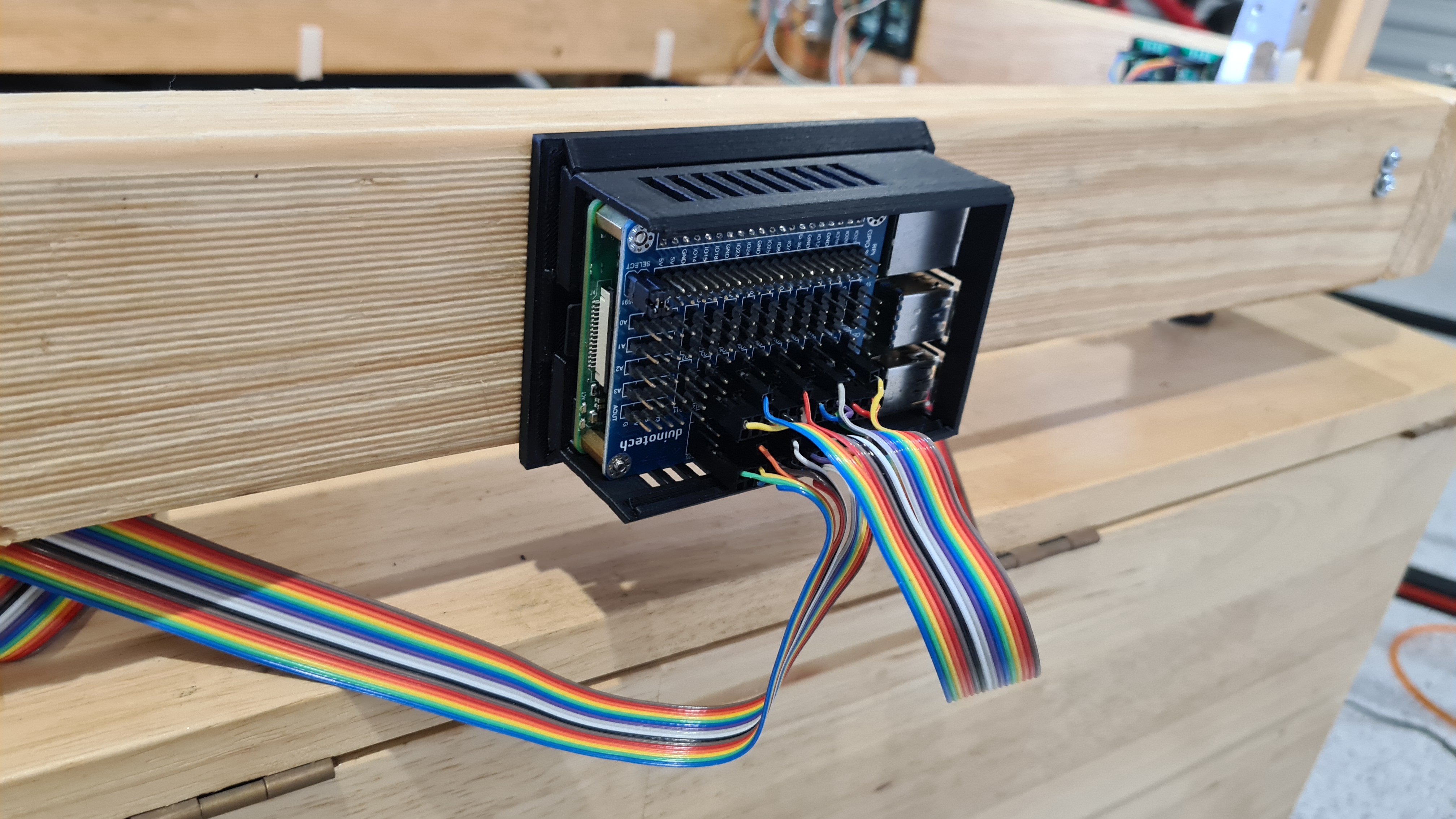

Another step was to get some nice box to hold our RaspberryPi. I’ve been lazy to start designing it myself so I’ve simply downloaded Raspberry Pi 4 Case, active cooled with wall mount from someone with nickname tipam and which looked pretty cool on a picture.

Mainly it came with a promise of a wall – mount, which honestly needed some more love and I actually ended up tweaking it myself to fit the testing rig beam. It all still worked out very nicely.

Final touch was a set of screws to reduce a surface area between the load cell and our cart. Serge sharpened them for me and here they come mounted.

Then I spent three weeks developing an app which would visualise readings from all those load cells.

RC Airship WP flight by Martin Hill

I’ve subscribed to Martin Hill’s videos couple years back – he does amazing stuff – while now he posted his two latest from 22 March 2022, which are showing some awesome details.

First video is from a cam on board of his blimp, when watching, don’t forget to notice voltage (10V) and current (1.* Amps) values in upper right corner!

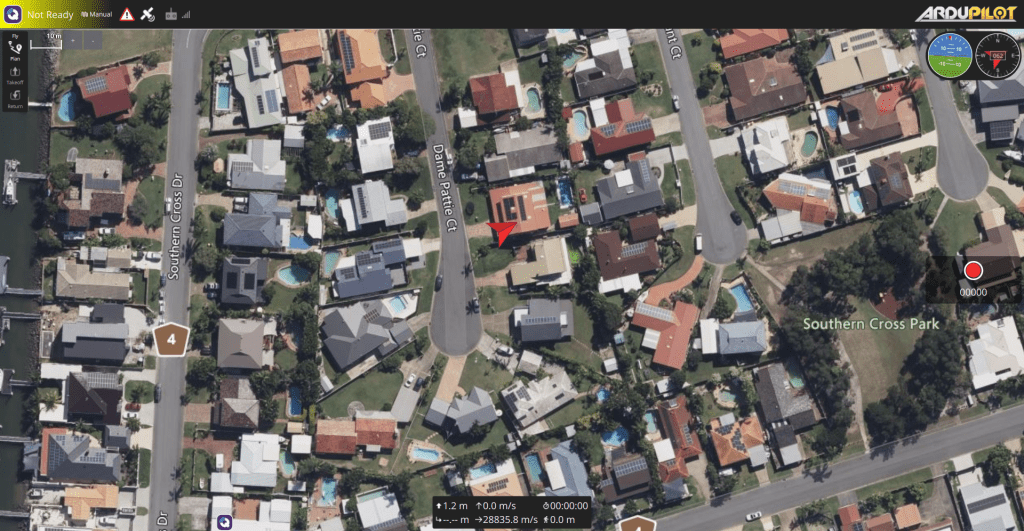

The second video appears to be from the same flight, but from the Ardupilot perspective – following predefined navpoints.

Well so this is amazing & well done Martin Hill! I wish we’ll be posting something very much similar with our BBBlimp project any time soon!

UPDATE 4th April 2022

Sebi told me that when presenting those Youtubes I’ve forgot one showing parts of the actual blimp flight. Thank you Sebi & here it comes!

Fatal Flight – THE TRUE STORY OF BRITAIN’S LAST GREAT AIRSHIP

This is going to be an unusual post – a book review of the Fatal Flight – The True Story of Britain’s Last Great Airship By: Bill Hammack!

But let’s start from beginning. Quite a while ago I’ve contacted Jesse Krizik from US, a real actual man owning the http://krizik.com/ domain! It is not a typical me to keep contacting random people, but it all got motivated by a story of František Křižík – a Czech’s Thomas Alva Edisson. I was simply elaborating about some different name for our project and following inspiration on Tesla, Nikola etc. Krizik seemed to be giving a pretty good foundation.

Anyway, Jesse came back almost instantly, quite surprisingly saying that this is an amazing coincidence that he’s just reading a book from Bill Hammack on a fate of one of the largest airships ever built. I couldn’t resist and ordered one from the Australian Booktopia. I didn’t know that such a service exists, but they printed it out for me on-demand and send me my-own copy, in an excellent shape and quality. Book arrived in a week and I sent following picture to Jesse to thank him for suggestion.

I hope it is not getting too boring, so let’s get back to the main story here. The book is written by Bill Hammack who an American chemical engineer, and Professor in the Department of Chemical Engineering at the University of Illinois at Urbana–Champaign. I never heard about him before getting a word from Jesse. Bill runs a technical series on Youtube and he has a gift to bring engineering principles to masses. I strongly recommend reading about him, going through his bibliography and watch his Youtube channel.

The book finally! Let’s say it that first 186 pages is a readable compilation of the R101 story from many sources, many of those never published before, with a nice touch of an artist to make it more acceptable (less boring) for today’s audience. Amount of “beef” varies chapter by chapter, quite likely correlating with information density of original sources. I understand that technical author can’t make up things to keep the pace, but this is perhaps my only critique to this book – some areas simply stand out how detailed they are (an engineer climbing a ladder, dinner menu), while standing next to the others where similar details would be appreciated (airship design history, building, multiple other test flights, aftermath).

But enough of that – it is how it is, Mr. Hammack clearly builds up a fascinating picture of one of the flying legends. Think about this book as a historical episode of the Seconds from Disaster TV show. With every page unfolding you are just getting better and better understanding why this amazing project ended up like it did.

I wonder, does documentaries work with a concept of “spoilers“? I suppose they don’t, but I still won’t go in too many details, but still let me present few interesting notes I made for myself.

As the first thing, I loved all Bill’s schematics in the book. As they are clearly saying “do not copy” I’m putting here just one – the Crew & Passenger decks and meanwhile I’ll ask Mr. Hammack to check if that’s ok.

Wikipedia intro: R101 was one of a pair of British rigid airships completed in 1929 as part of a British government programme to develop civil airships capable of service on long-distance routes within the British Empire.

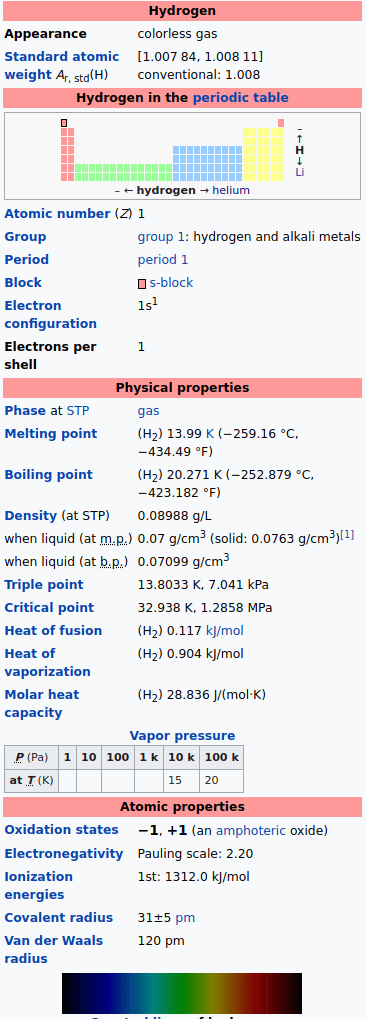

- Hydrogen gas bags were made from oxen entrails – 50.000 of them! All imported from the South America. Why oxen entrails? Because there were no plastics invented yet in 1920! That all came more like 30 years later in 1950s.

- It’s rigid structure (dead weight) ended up weighting 110 tons, that was a big failure as an overall lift generated (under the best conditions) was 140 tons, leaving just 30 tons for a “disposable lift”. Those are quite a difficult numbers, when e.g. A380 comes with 664 tons of lift (payload)

- Appendixes! All of them just brilliant, but the Appendix D – The report on flight in the Graf Zeppelin and visit to Friedrichshafen by Lieutenant-colonel V. C. Richmond and Squadron leader F. M. Rope – This is clearly a must-read! Fascinating story in every paragraph with so many historical overlaps.

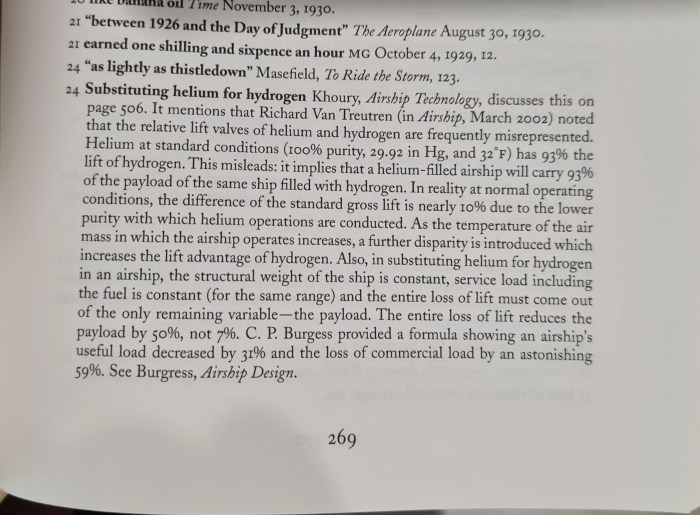

Finally, the appendix called just “Notes”. Every its line, just a treasure, while the note #24 took me completely by surprise.

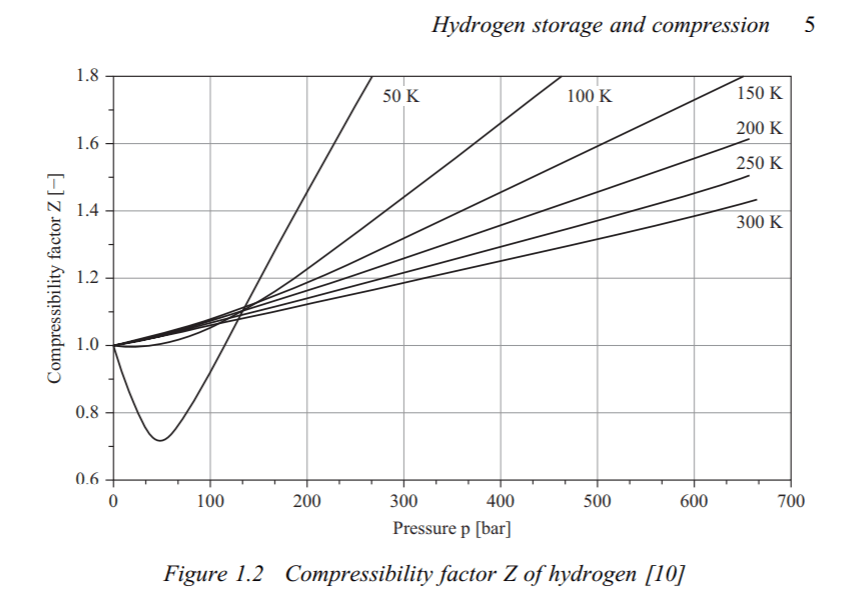

Yes, what it says is that when comparing the relative lift valves of helium and hydrogen – the difference (loss) of commercial load of the helium airship is incredible 59% to the hydrogen one! I suppose I am very much biased here by our hydrogen airship project, still I find it amazing to find such a strong supporting claim.

Yes, I’ve instantly ordered the Airship Technology by Khoury from Booktopia. Let’s see if it is really there! 😀

Update I. (21st March 2022)

As a reaction on this review I’ve received a comment pointing to a song from Iron Maiden (which is not usually on my daily playlist) called “Empire of the Clouds”. Quite surprisingly this song is wrapping the faith of our R101!

Mist is in the trees, stone sweats with the dew

The morning sunrise, red before the blue

Hanging at the mast, waiting for command

His majesty’s airship, the R101

Iron Maiden – Empire of the Clouds

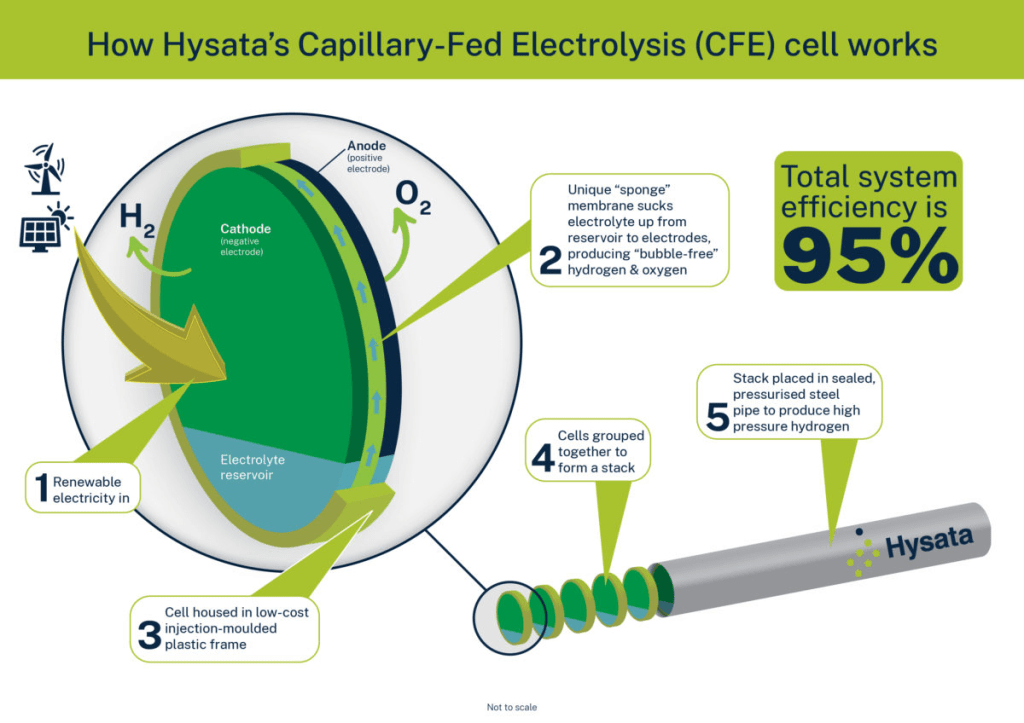

Green Hydrogen under $2 AUD per kg

Hysata company from Wollongong NSW, claims that their electrolyser can produce Hydrogen with a total efficiency of 95%!

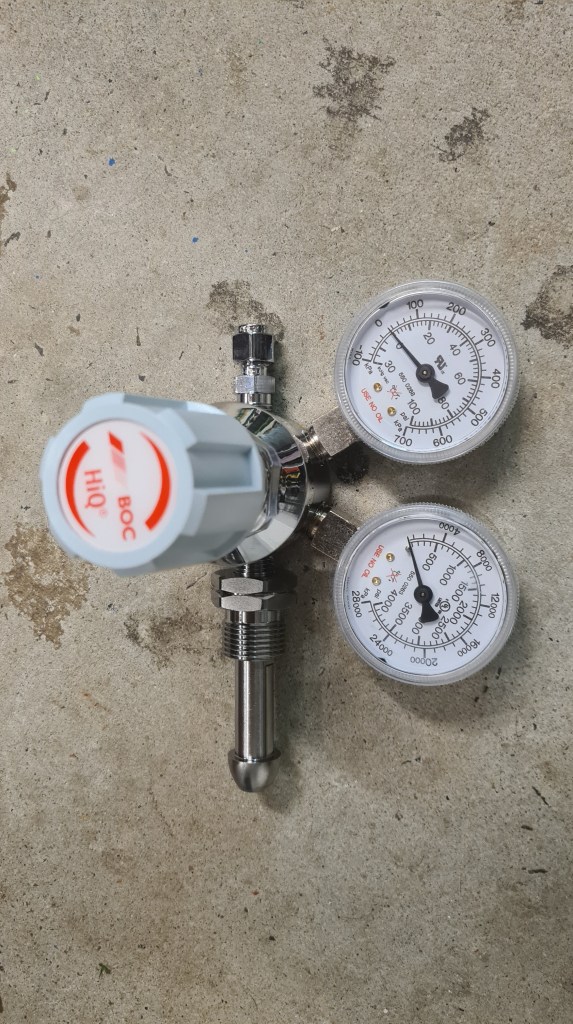

Why 95%? 95% efficiency would mean that a green Hydrogen can be produced for less than $2 AUD per kilogram (it was $20 per kg last time I was getting it from BOC a year ago). More details here.

How Airships Could Overcome a Century of Failure

While working on many other things (testing rig, burned servos replacement, laser cutter, CP tube jig … ) Martin sent me this awesome video made just recently for BBC – Thank you Marting – and you all enjoy! 🙂

Edit: As I’ve been sending it all around with my comments, Murray have been able to summarise whole story in one simple sentence, which I really liked:

100% agree with the point that after the Titanic we didn’t give up on ships!

Murray

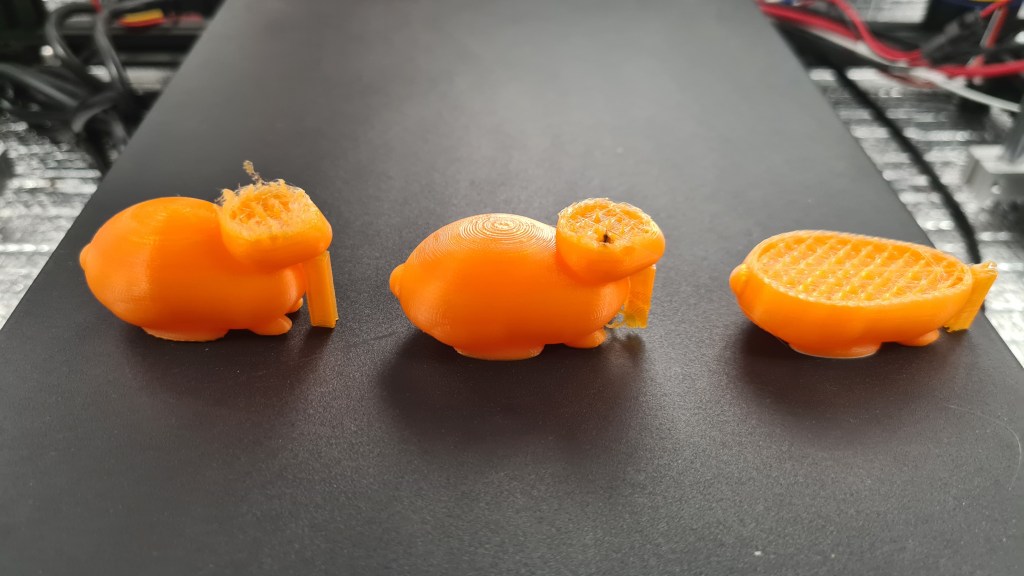

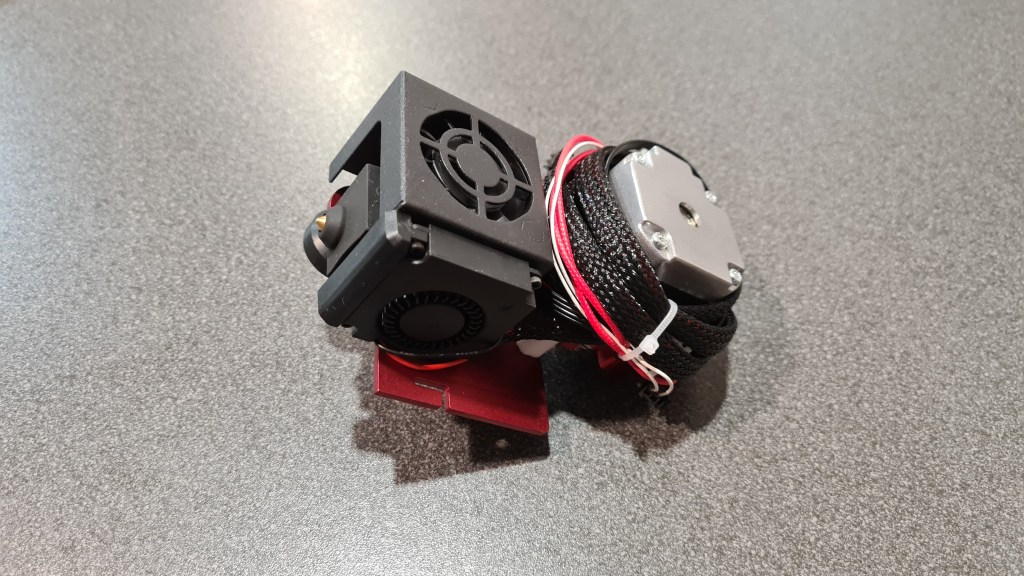

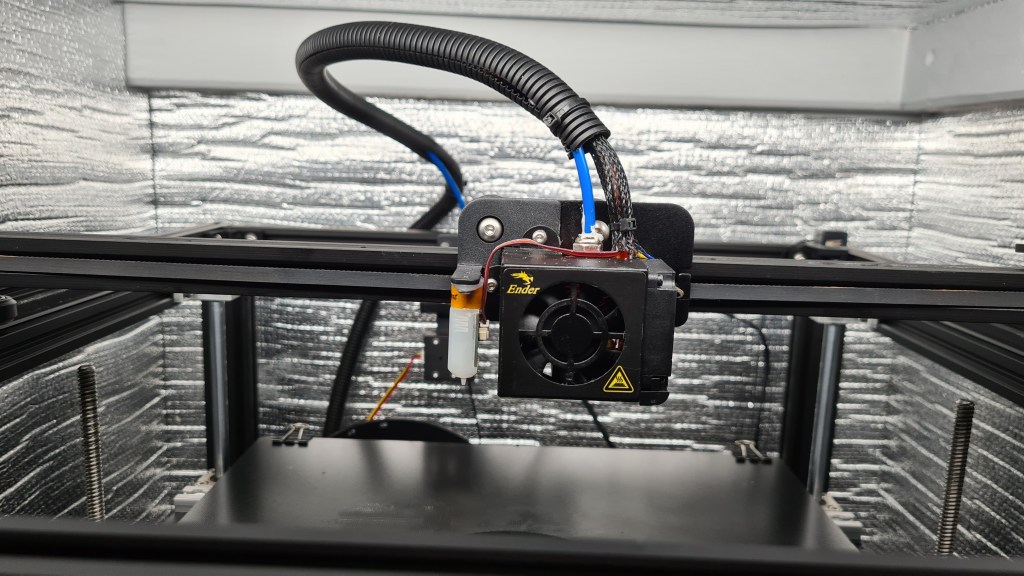

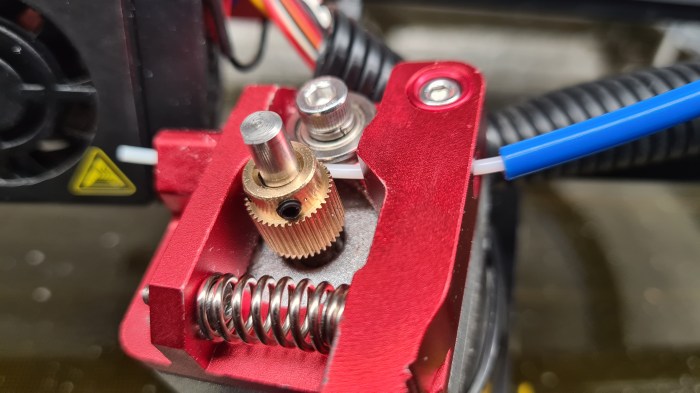

Printer maintenance

I’ve got few failed prints lately, well little bit more than usual. So I blamed our garage not providing too stable conditions through the Queensland summer first, while did a bit of check on the printer condition and found the brass drive extruder gear wheel being bit worn out too.

It took few moments to order a set of new ones from eBay.

… and then 3 weeks to get them delivered.

Comparing a new one with the old one – there was not too much difference. Yes the old one looked bit used, but I don’t think it was nothing too serious to prevent it doing it job.

While having it all in pieces, I’ve cleaned up all relevant parts and did some tightening to get it ready for another printing marathon.

Looks good, doesn’t it? 🙂

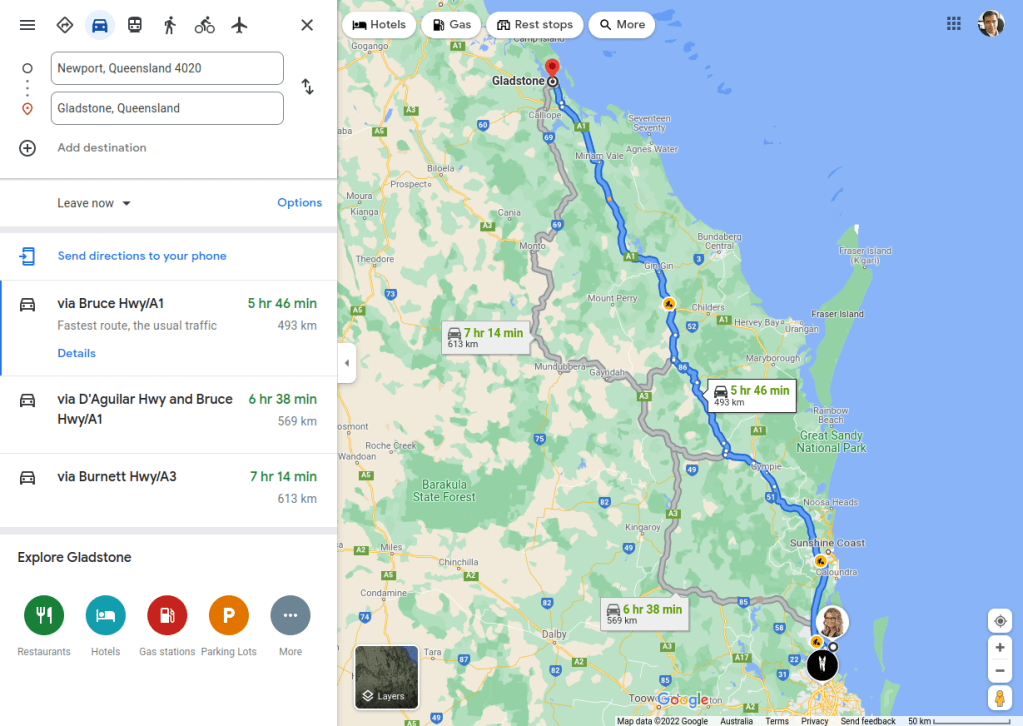

Visit To CQU

It is hard not to bump in some very interesting people, when walking around with an hydrogen airship project. So I’ve ended up being introduced to Mr. Murray Shearer a head of Hydrogen and Alternative research from Central Queensland University.

After several calls and missed opportunities things worked out that I had a somehow a trip around one of the CQU’s departments – the one in Gladstone.

I had an great time chatting with Murray for couple days there, including an exclusive tour over the uni campus. Our main topic was our hydrogen airship project and I couldn’t resist and told Murray everything, including a practical demonstration of our jet-cart.

It has to be something mysterious with these live demonstrations, that things usually don’t go as planned. Well it wasn’t different this time when one of our front propellers got loose/stuck in the moment of the highest performance and ripped off one of front intakes with pretty spectacular acoustic effect.

Luckily it was after our main demo and also it looks like Murray’ve seen things like that before (he holds a doctorate in explosions). Anyway, next day we did an excursion over the campus to check on some of its potential. I took several pictures to have some good material for our blog readers.

Huge thanks to Murray for this opportunity – it was awesome in many ways and I really enjoyed all my stay there. Hopefully we’ll have a chance to catch up soon again!

Coding from Beach Feb Meet and Greet

I am in touch with the Coding from Beach team for years – Ben, Ric, Chris, the other Chris … .

So we went with Sebi there yesterday (4th Feb 2022) and presented our current project status and it was fun. As you can see on faces below – everyone got amused and we’ve got plenty of interesting questions on what, how and where next.

I was excellent to get feedback from you guys – as always. Thank you for your hospitality and giving us a chance to present our project!

Testing rig upgrade

Our plan to have a proper testing rig for our airship controller got hit by several issues. First – as it wasn’t the first priority, there was always a reason for not progress on its development. Second those rubber-bands I envisioned to keep it flying haven’t been reliable enough.

On a picture below you can see how that rubber rips in pieces when confronted with its copper wire attachment.

Thinking about it for a while I came with a plan to reuse some old copper tubes to create some more solid attachment mainly employing more surface together with doubling amount of rubber involved. As always I took few pictures to at least briefly document that process.

What’s not on pictures is that I’ve ended up struggling to push both rubber ends through that copper ring. Some really old memory of my father came with an idea of using just a common hand-soap to help it a bit and that did the trick! Thanks daddy!

Anyway, Sebi couldn’t resist to give it a proper go. 🙂

Sebi demonstrates power of all motors combined, so don’t forget to stay to the end! As always, let us know your ideas, any constructive comments are always welcome! 🙂

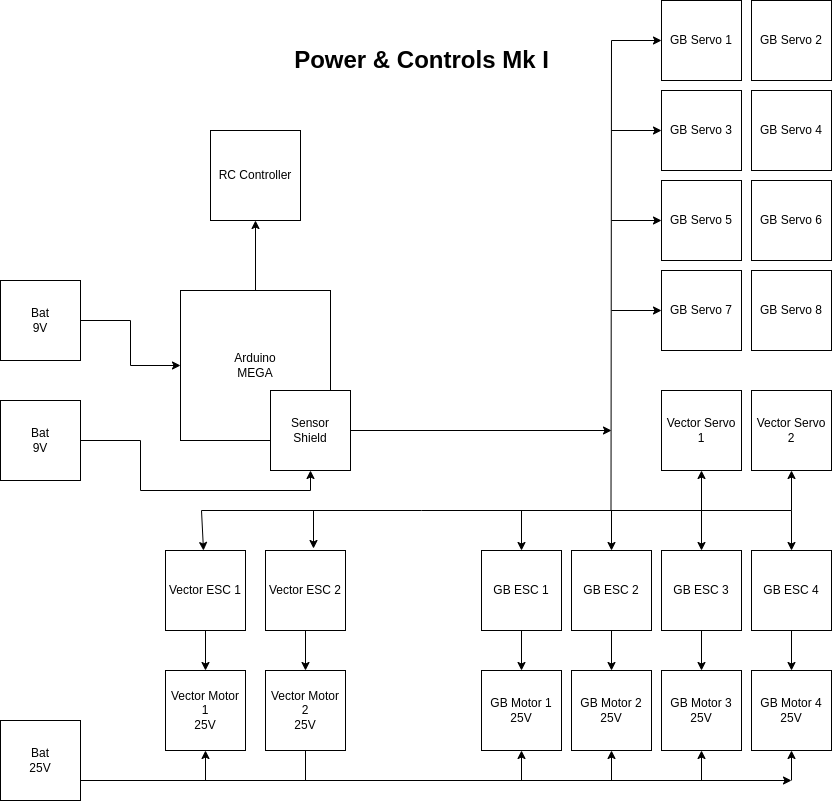

Power management update

Progressing with our controls development we’ve ended up with a “too many batteries” dilemma. I’ve captured our current situation on a diagram below.

As you can see it we currently need our “big fat” 25V battery + couple of 9V batteries to feed Arduino MEGA + its Sensor Shield.

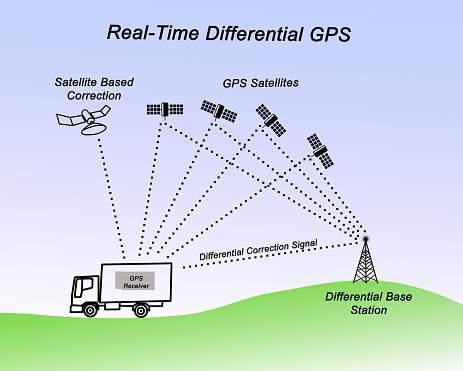

Situation got out of control when we are now adding BeagleBone Blue and GPS shield to the whole scope. Luckily Richard told me about an option to move in a DC to DC converter to reduce number of batteries to the main one (at least for now till we’ll need to have BBB on its separate power rail).

Local Jaycar provided suitable DC to DC Step Down Voltage Converter Module.

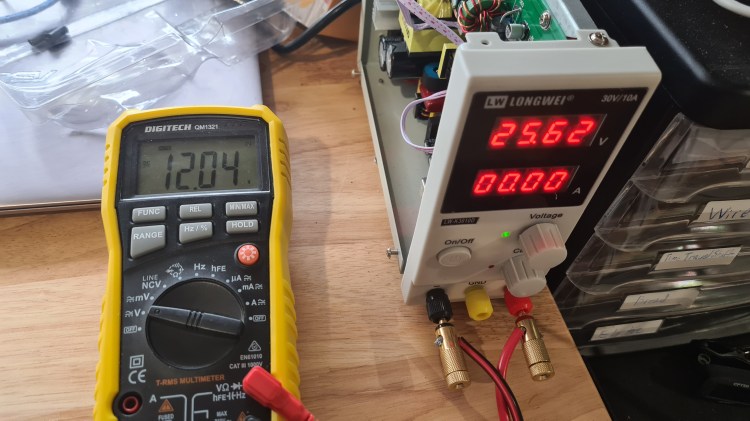

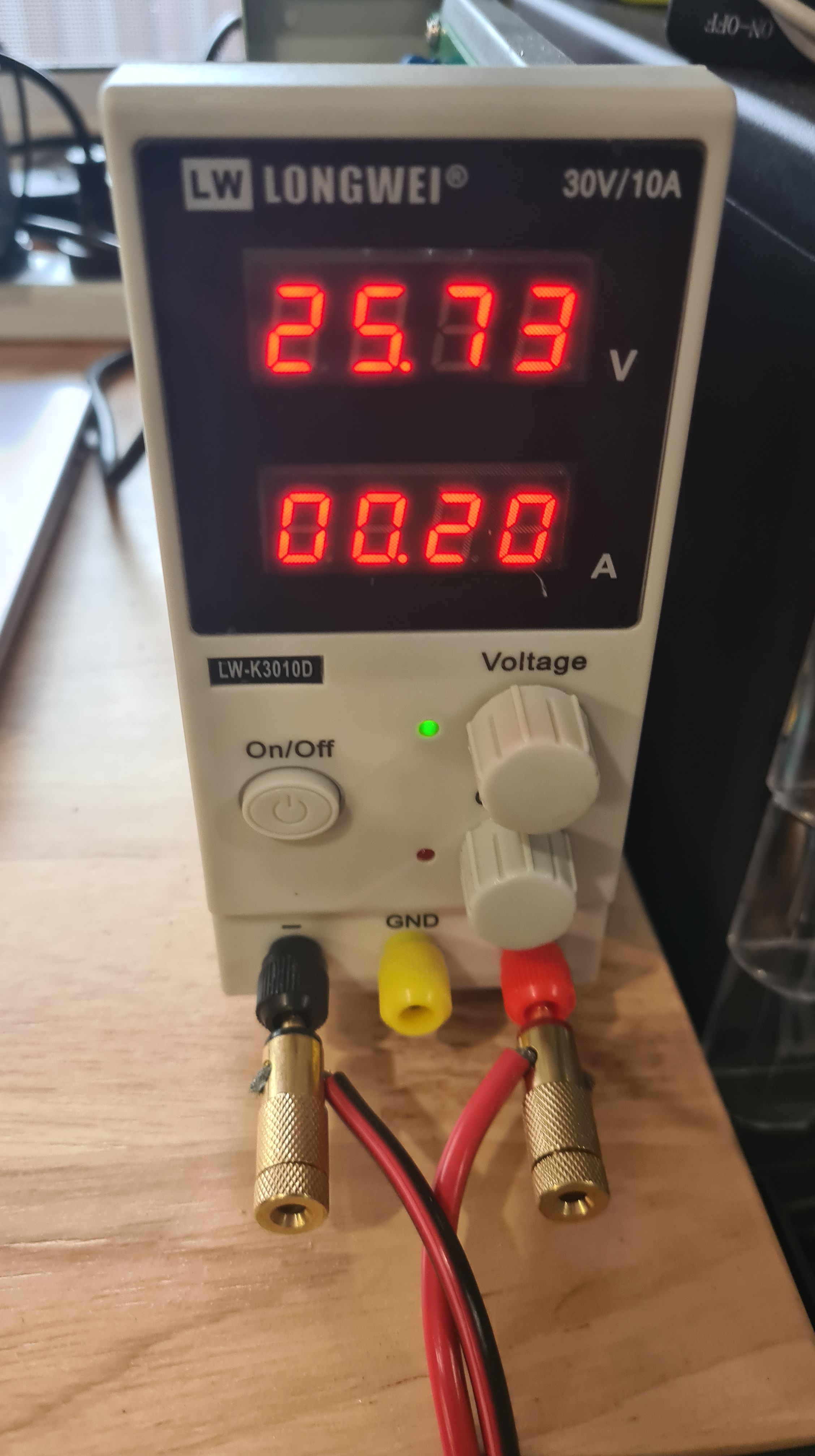

.. and I did some testing with it before hooking it up. As you see on the picture below, I am using our power supply to feed in 25V and our multi-tool detects 12V on the output.

It looks pretty nice, doesn’t it?

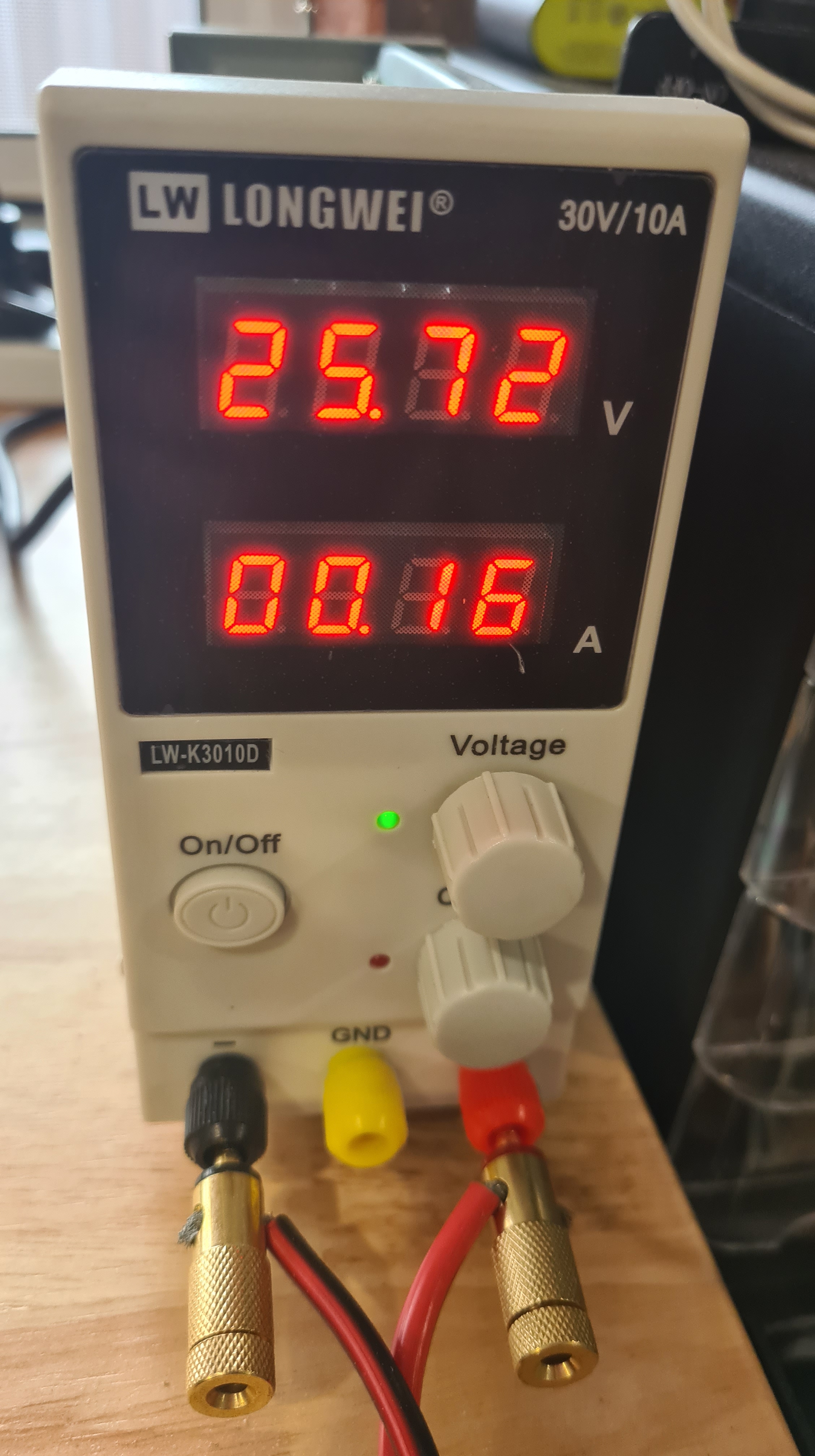

At the end I hooked it up to BBB and to Aruduino with all servos / ESCs / RC receiver / GPS powered up and it came with drawing roughly 0.36A altogether. That should do!

Finally – it is all mounted in. On a picture below you can see cables connecting our main power bridge (blue and black) going in the DC to DC converter and than from there in the Arduino MEGA.

We did some preliminary testing with Sebi and it might be that that Sensor Shield draws more power than that DC 2 DC can provide, so it is hard to say if this is a final solution. Well, stay tuned and fingers crossed!

Ardupilot

ArduPilot is an open source, unmanned vehicle Autopilot Software Suite.

This is the tutorial I am using to set up ardupilot on the beaglebone blue: https://github.com/imfatant/test

We are using ardupilot because we saw a youtuber by the name of rctestflight using it and it looked like it worked well(and it does).

In order to edit the ardupilot config access this file /etc/default/ardupilot also other settings are changeable in the file here: (for example console should be linked with the GCS’s (Ground Control Station’s) ip address) http://ardupilot.org/plane/docs/parameters.html?highlight=parameters

Other possibilities exist, namely:

Switch -A --> "Console", SERIAL0, default 115200

Switch -B --> "GPS", SERIAL3, default 57600

Switch -C --> "Telem1", SERIAL1, default 57600

Switch -D --> "Telem2", SERIAL2, default 38400

Switch -E --> Unnamed, SERIAL4, default 38400

Switch -F --> Unnamed, SERIAL5, default 57600

Also, keep in mind that in order to connect with GCS the beaglebone blue will need wifi do this through the connmanctl. A problem sometimes is that the wifi is disconnecting I fixed this by connecting my own antena.

This file exists just in case you need to change some settings: /usr/bin/ardupilot/aphw

Lines 5 to 7 of the file switch on power to the BBBlue’s +5V servo rail – i.e. for when you’re using servos. Not necessary for ESCs.

Line 8 enables the PRU(programmable real-time unit). https://beagleboard.org/pru

To get ArduPilot going, choose which flavour you want and type ONE of these: (I have changed this process on my beaglebone blue)

sudo systemctl enable arducopter.service

sudo systemctl enable arduplane.service // no executable

sudo systemctl enable ardurover.service

sudo systemctl enable antennatracker.service /// no executable

After you reboot, your ArduPilot should inflate automatically. Look for the flashing red LED!

It’ll help to familiarise yourself with systemctl (https://www.freedesktop.org/software/systemd/man/systemctl.html). Some useful example commands:

sudo systemctl disable <name of service>

sudo systemctl start <name of service>

sudo systemctl stop <name of service>

Just in case the ArduPilot parameter settings files: /var/APM/{ArduCopter.stg,ArduPlane.stg,APMrover2.stg,AntennaTracker.stg}

I start my ardupilot through a .sh file, all it does is it calls the executable with the right parameters, this is where you should change the ip. ardupilot.sh

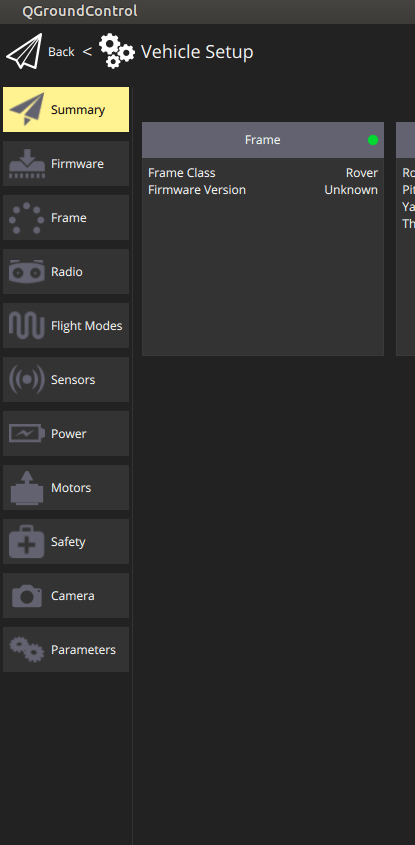

Download either Mission Planner (http://firmware.ardupilot.org/Tools/MissionPlanner/MissionPlanner-latest.msi) for Windows or QGroundControl (http://qgroundcontrol.com/) for Linux & Windows. Both these programs will connect to streams of MAVLink data coming over the network (via UDP on port 14550, for example) or over COM ports.

If you’re having difficulty establishing a link, look at the following:

- Ensure you’ve opened the necessary ports in the GCS computer’s firewall. Perhaps even disable the firewall temporarily.

- Be absolutely certain of the GCS computer’s IP address, because if you happen to be ‘dualing’ Windows and Linux on the same machine, routers will sometimes assign different IPs to each of the OSes.

- If you’re getting a ‘port is already open’-type error, turn off the GCS software’s auto-connect feature, restart the program, and try again manually.

- Remember that a server set to listen on the loopback address (127.0.0.1) won’t see external nodes on your network.

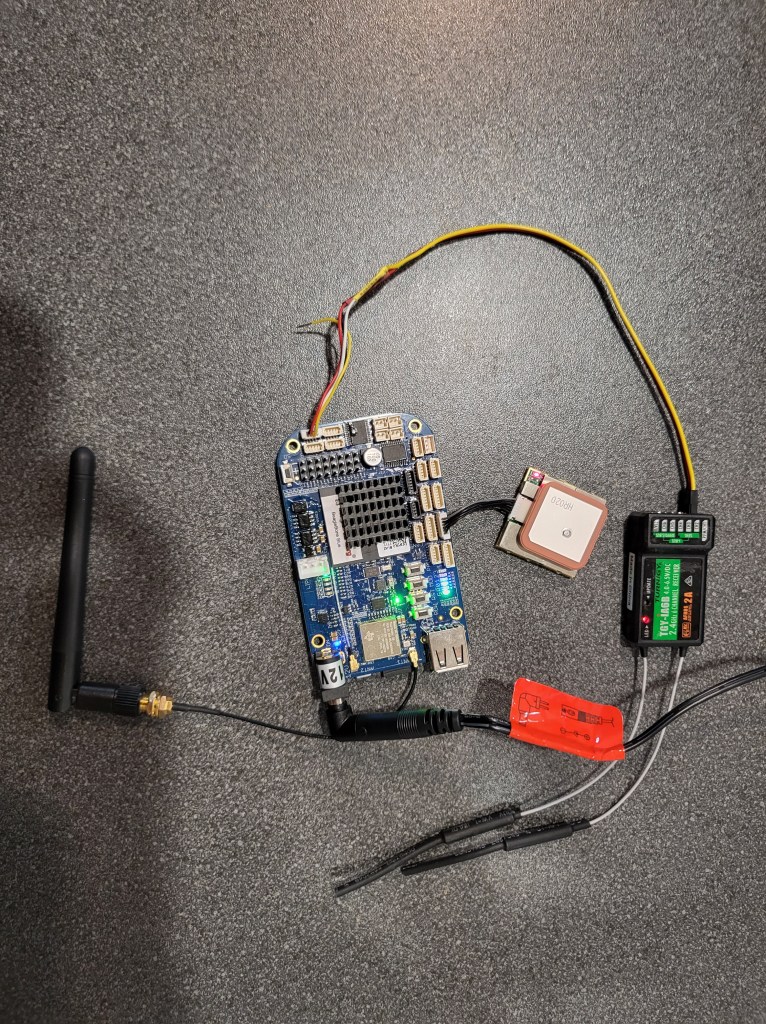

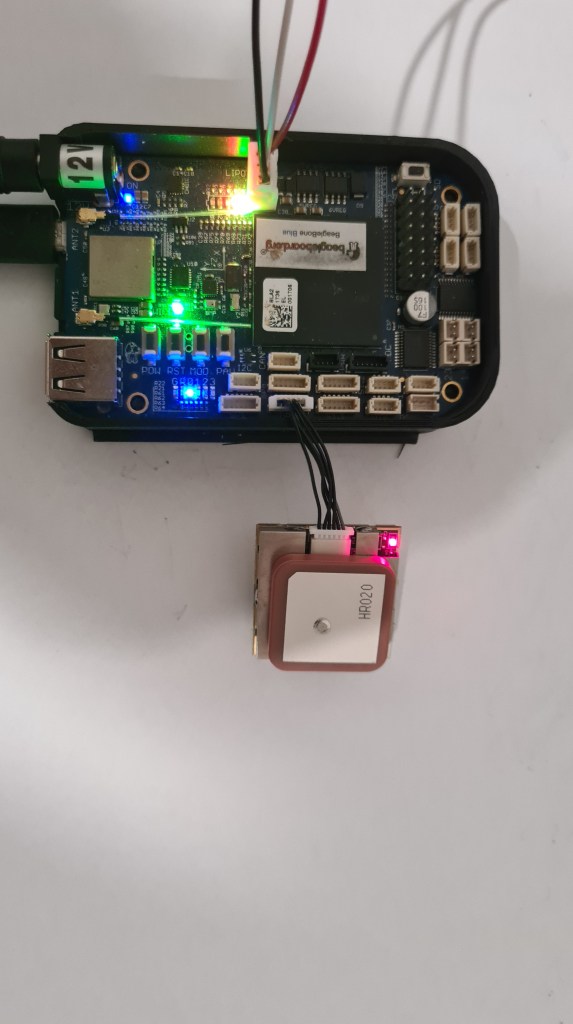

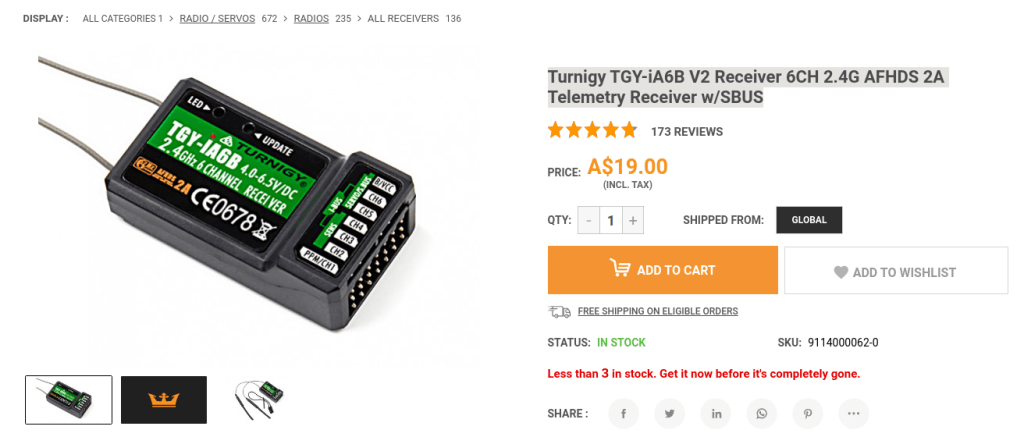

To make sure you are doing it right this is my setup of connections also I am using the em-506 GPS and a simple reciever with ppm connected to the 3v3 and gnd and the sbus pins on the bbb like so:

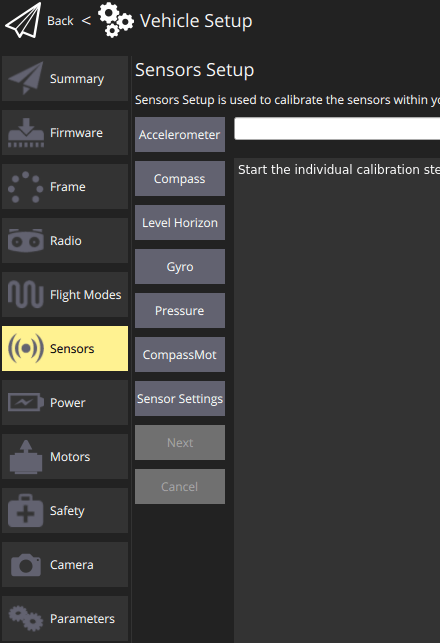

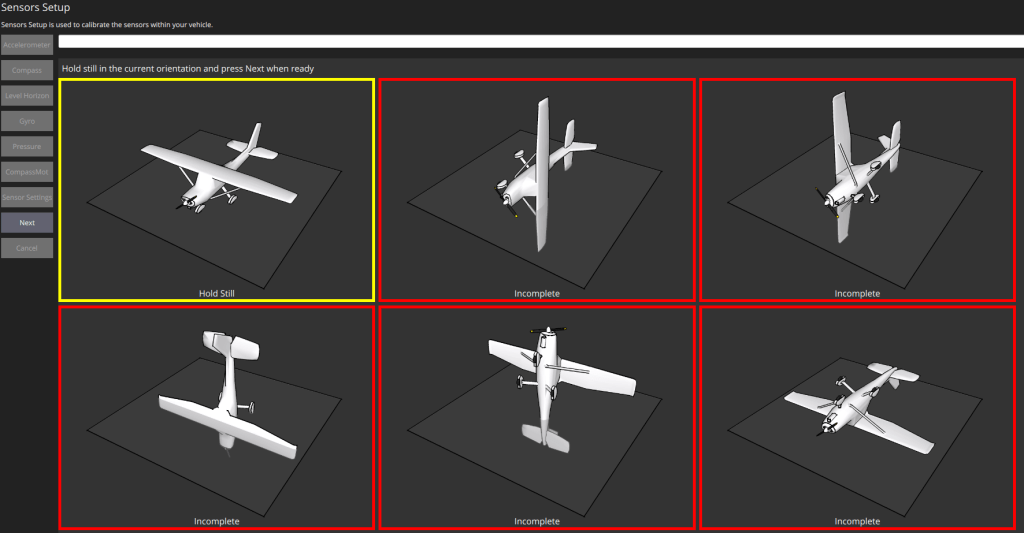

After that open your GCS’s software and it should automatically connect with your computer. When I first started up the software I needed to calibrate some of the beaglebone’s sensors so if there are any difficulties consider re-calibrating the sensors.

You can re-calibrate by going onto your GCS: mine is QGroundControl; click on the top left icon, click on your sensor. and then follow the prompts to re calibrate.

I have also added this command: sudo ./ardurover -C /dev/ttyO1 -A udp:192.168.0.191:14550 -B /dev/ttyO2 -F /dev/ttyO5

To run on startup because the services aren’t working for some reason: you can edit it with this: sudo crontab -e

Oh and this command aswell to power the power-rails: ./usr/bin/ardupilot/aphw

At the end all I need to run ardupilot is to ssh to my bbb and then run the ./ardupilot.sh script.

If all works in the end you should end up with a red flashing led on your bbb and a neat looking ardupilot GCS.

GPS on our garden

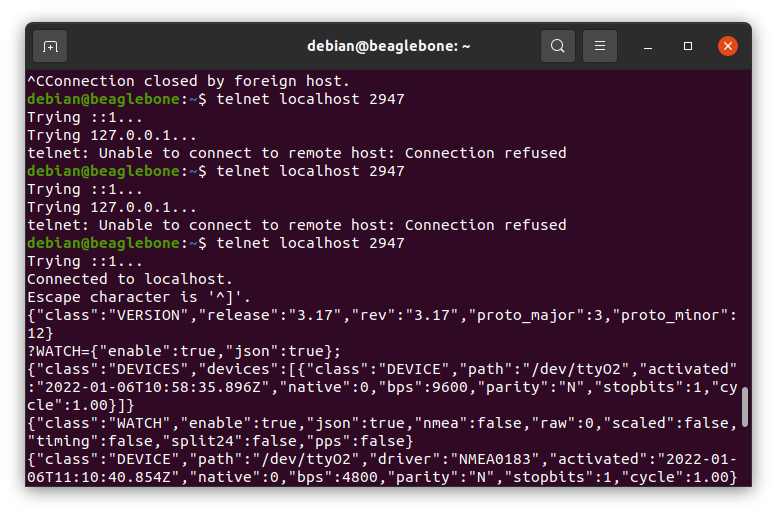

As per our yesterday’s post – our initial GPS accuracy test was horrifying. So I discussed this with Andrew and he suggested to give it a go with something more sophisticated like gpsd — a GPS service daemon. It took just a moment to set it up on our BeagleBoneBlue as gpsd is one of commonly supported packages on Linux.

debian@beaglebone:~$ sudo apt install gpsd

[sudo] password for debian:

Reading package lists... Done

Building dependency tree

Reading state information... Done

gpsd is already the newest version (3.17-7).

0 upgraded, 0 newly installed, 0 to remove and 1 not upgraded.

Then we hit a bit of trouble when installation actually starts the gpsd daemon on its own and there’s been a conflict on sockets, but couple of systemd commands sorted it out.

debian@beaglebone:~$ sudo systemctl stop gpsd

debian@beaglebone:~$ sudo systemctl stop gpsd.socket

And finally we’ve been ready to launch it.

debian@beaglebone:~$ sudo gpsd -D 5 -N -n /dev/ttyO2

Now querying it with telnet on socket 2947 comes with nice “welcome” message.

debian@beaglebone:~$ telnet localhost 2947

Trying ::1...

Connected to localhost.

Escape character is '^]'.

{"class":"VERSION","release":"3.17","rev":"3.17","proto_major":3,"proto_minor":12}

Next stage is to enter “?WATCH={“enable”:true,”json”:true};” to set gpsd to the observing mode and start us feeding back.

I’ve left it running for few moments and picked random message like this:

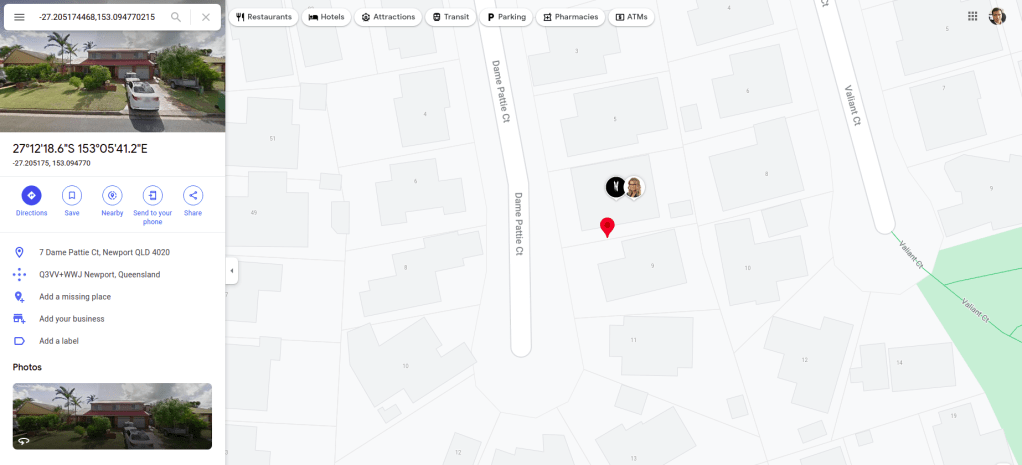

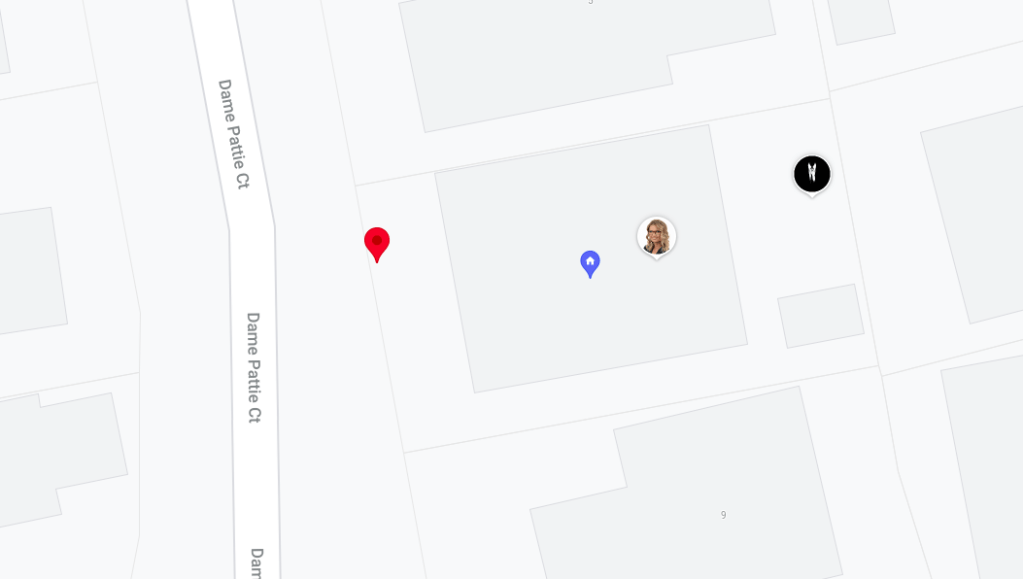

{"class":"TPV","device":"/dev/ttyO2","mode":3,"time":"2022-01-06T11:12:21.000Z","ept":0.005,"lat":-27.205174468,"lon":153.094770215,"alt":0.258,"epx":20.312,"epy":16.881,"epv":87.471,"track":261.5038,"speed":0.170,"climb":-0.049,"eps":40.62,"epc":174.94}

There you can see information in a much nicer (human readable) form which gave us coordinates like: “lat”:-27.205174468,”lon”:153.094770215 and that thrown us to our neighbours!

Seeing how those values were fluctuating, we went out with Sebi and did one more measurement in front of our house.

That went spot on! I think it was like about a meter from us. That’s what we needed. Next step – telling this information to our jet-cart and making it move along waypoints – that’s going to be the real fun! 🙂

How to connect GPS to BeagleBoneBlue

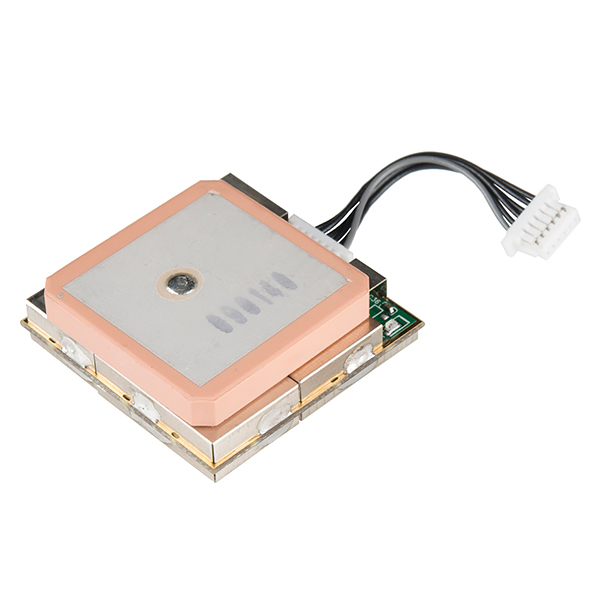

Santa recently brought us a brand new GPS Receiver – EM-506 (48 Channel). He clearly had to read a GPS BUYING GUIDE as this is exactly what we just needed!

- 48-Channel Receiver

- Extremely high sensitivity : -163dBm

- 2.5m Positional Accuracy

- Hot Start : 1s

- Warm Start : 35s / 15s with CGEE

- Cold Start : 35s / 15s with CGEE

- Power: 45-55mA at 4.5-6.5V

- Size: 30mm x 30mm x 10.7mm

- Weight: 16g including cable

I’ve left Sebi to explore it for couple days, but at some stage he got stacked and couldn’t move forward. It looked like that device is not sending any signals. Well when you get seriously lost it’s a time to RTFM!

On a picture below you can see in a left bottom corner the GPIO and serial JST connectors table. The one we are after is UART (Universal asynchronous receiver-transmitter) labelled as UART (GPS).

However connecting our GPS module to that connector did nothing – like completely nothing. Our BBB didn’t register anything, the LED on that EM-506 practically dead.

Another source of information than was EM-506 Datasheet which sort of indicates that it is a potentially power-hungry beast needing 45-55mA at 4.5-6.5V. And that gave me a clue to connect an external power – and voila – RED LED finally turned ON!

Well, Red LED is on .. but what it actually means? Documentation is quite sparse here, not mentioning anything about its colour.

LED indicator for GPS fix or not fix

LED OFF: Receiver switch off

LED ON: No fixed, Signal searching

LED Flashing: Position Fixed

So let’s assume it is powered on. Now how do we read any data out of it? It took a quite a bit of Googling and finally I was able to cross-reference some clues from different projects which indicated to use the tio – a simple TTY terminal I/O application to easily connect to TTY devices for basic input/output. However there are plenty of those on our BBB.

Reading more through the BBB UG, I sort of ruled out that those /dev/ttyOx are those we need to check and started poking them one by one and at some stage one of them (/dev/ttyO2) started printing some garbage on the screen!

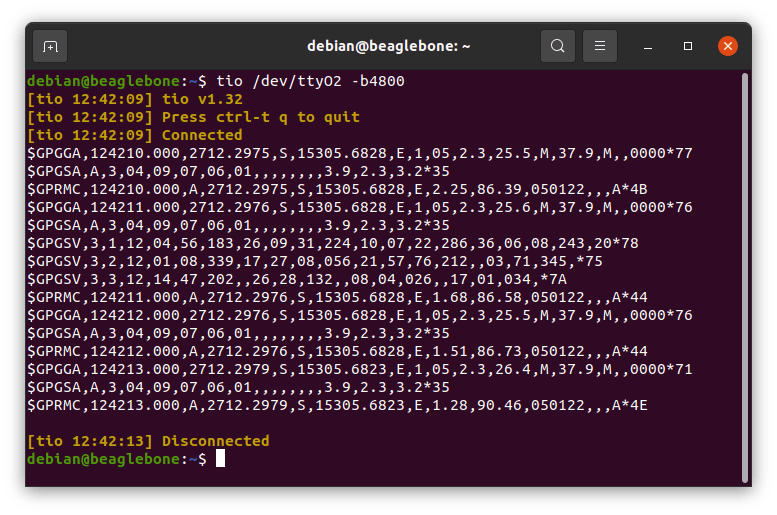

Sebi quickly suggested that this is a wrong baud rate and while documentation was again bit too flexible about which baud should we use (Baud rate based on flash memory setting), we applied trial & error approach again and got a text data out on 4800 bauds!

Also our mysterious RED LED started flashing! So what are we looking at?

$GPGGA,124210.000,2712.2975,S,15305.6828,E,1,05,2.3,25.5,M,37.9,M,,000077

This is GPGGA – Global Positioning System Fixed Data Output command

UTC Time 124210.000 hhmmss.sss

Latitude 2712.2975

Southern Hemisphere

Longitude 15305.6828

East

Postion Fix Indicator 1 (GPS SPS Mode, fix valid)

Satellites Used 05

Horizontal Dilution of Precision 2.3

MSL Altitude – +25.5 meters

Geoid Separation +37.9 meters

Diff. Ref. Station ID 0000

Checksum *77

Translated to the GoogleMaps it takes us across the water to Beachmere, Queensland, Australia. Why there (Beachmere is about 10km away) and not to our house? No idea yet, but that’s clearly for another day. 🙂

,

Test #3 – steady improvements in a correct direction

So we have our Gimbals upgrades mounted, added some minor clamps for batteries so they don’t go crazy anymore and battery is fully charged again.

On top of those hardware changes, I’ve recalled that Sebi had some significant difficulties with steering – mainly to keep our card straight on a narrow pavement with and even without a cross wind. We had a discussion on this and Sebi’s been able to demonstrate our problem with a balancing pencil on tip of his finger – or holding it hanging for its tip.

Well, this all made me thinking and I’ve got consequently dragged into some serious reading. Long story short, there are two main competing aircraft configuration concepts – Pusher configuration and Tractor configuration, while with our project we are hitting both with the third one – Push-pull configuration.

Aside of this I thought that providing bit of that “pull” configuration to move center of balance back might be beneficial so I instructed Sebi to code one of his 3-opts switches on his remote to behave like this:

1/ Only front gimbals are operational, rear ones are in their default position – to be used as a default for going forward or for sharp turns.

2/ All gimbals are operational – to be used for initial acceleration, strafing sideways and when full power is needed.

3/ Only rear gimbals are operational, front ones are in their default position – to be used when reversing.

It took Sebi no time to have it ready and I took video of him describing what’s going on.

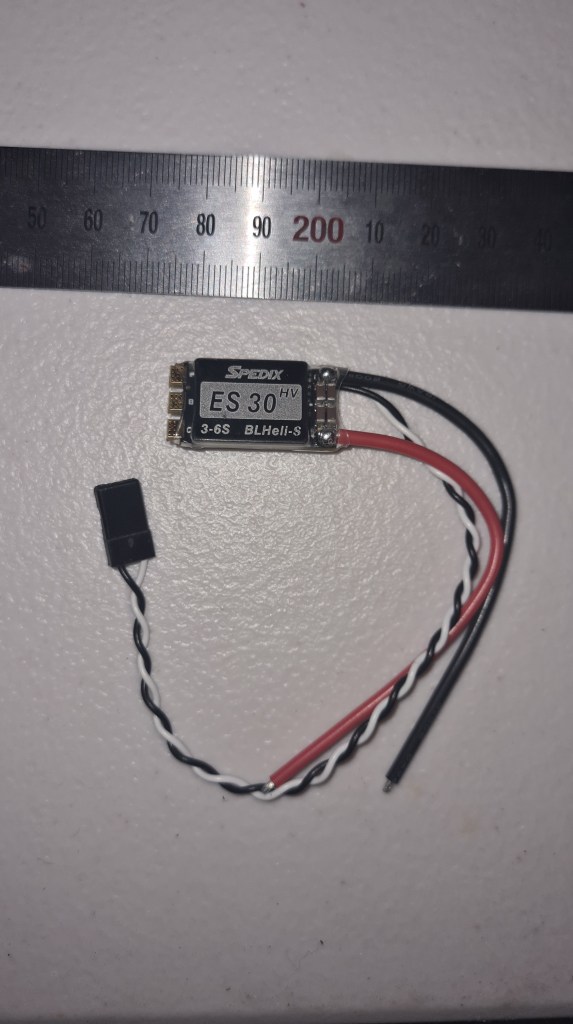

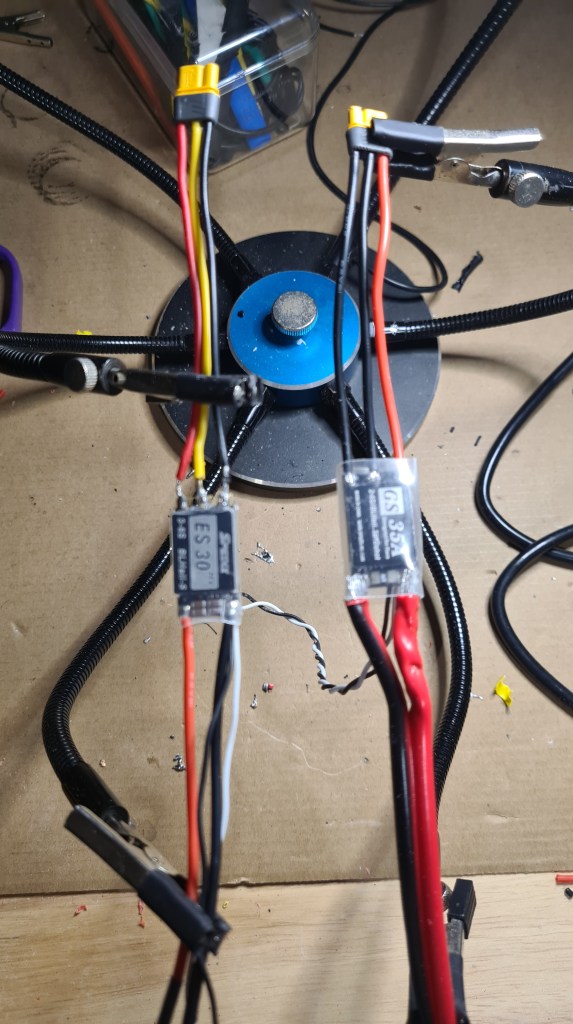

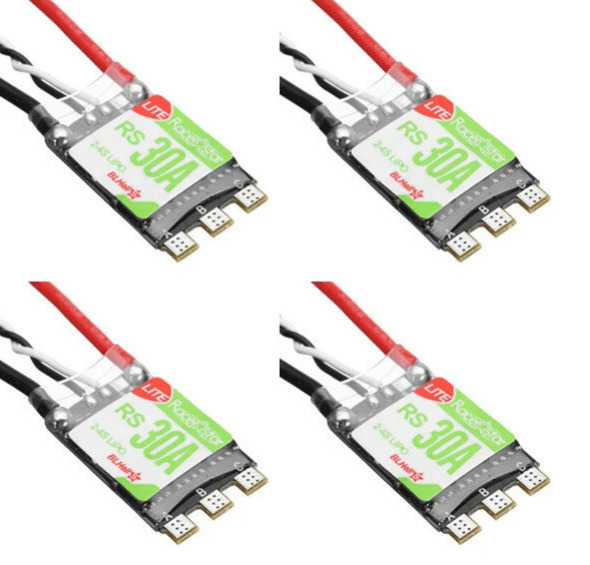

And we’ve been heading for another test! Well not that fast – just when we’ve been about to start we’ve realized that two 4S ESCs (yes, 4S while we are running on 6S – they’ve been mounted as a temporary replacement) burned out so it took another couple hours to solder in new set.

Ok, now! Sebi will try to go around a blue mark on our local roundabout.

That went pretty well, didn’t it? You could see Sebi switching between mode 1 for keeping directing and mode 2 when he needed to accelerate or do a bit of strafing.

When it goes so well, let’s try a speed test!

That was pretty fast and it was still accelerating! In the last second you can see that Sebi used all 4 gimbals in a reverse-regime to do an emergency stop – super-cool! 🙂

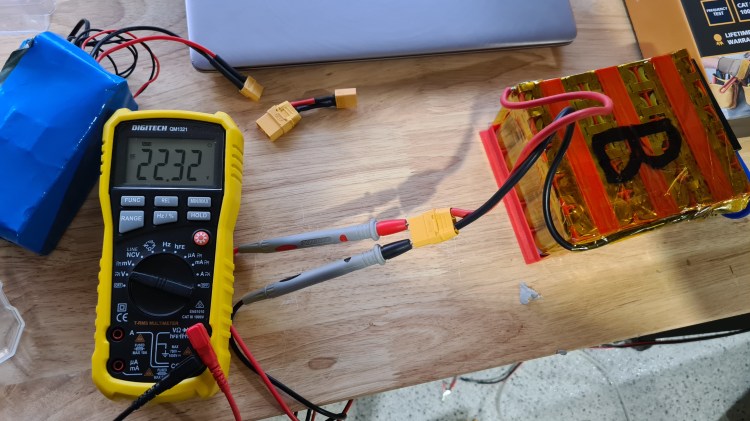

Then we went to the shore to have a bit more fun scaring people and dogs from a pavement and after while I noticed couple of minor defects there. One of the motors got ripped off from its seat again when it lost a screw and propeller lost few blades when hitting the ring. Also another propeller started sliding out from its axle, while quite interestingly still stayed on. But all the rest was holding like nailed.

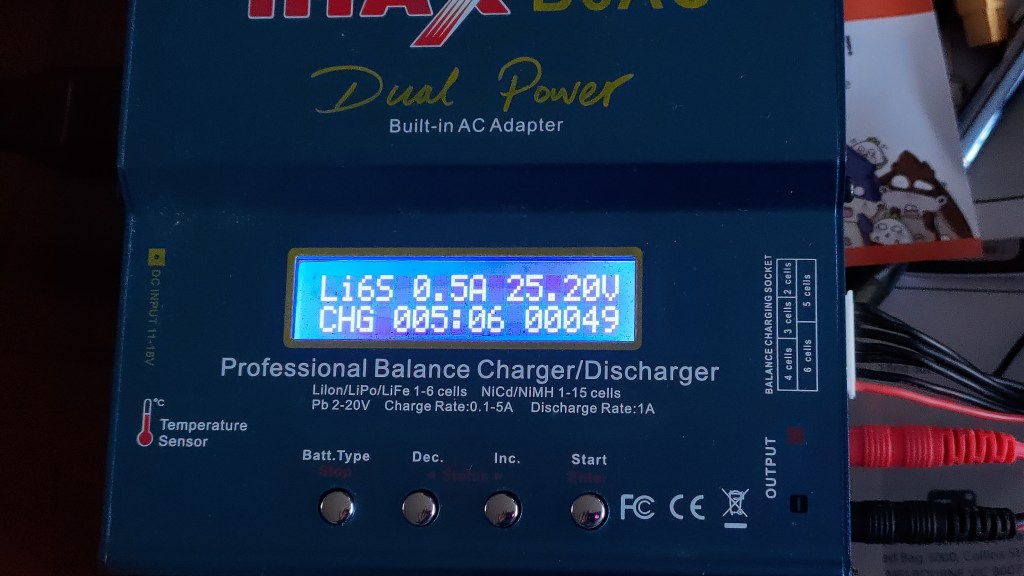

Finally Sebi asked me to check remaining battery power and it came with 22.66V ~> battery being still generously 68% full (min 17.4V, max is 25.1V) and that’s after 30mins + of being very naughty. These battery values are making me pretty happy.

All done for today, I can see we are making some good progress here again! Hope you are liking it too and as always let us know anything what comes to your mind. 🙂

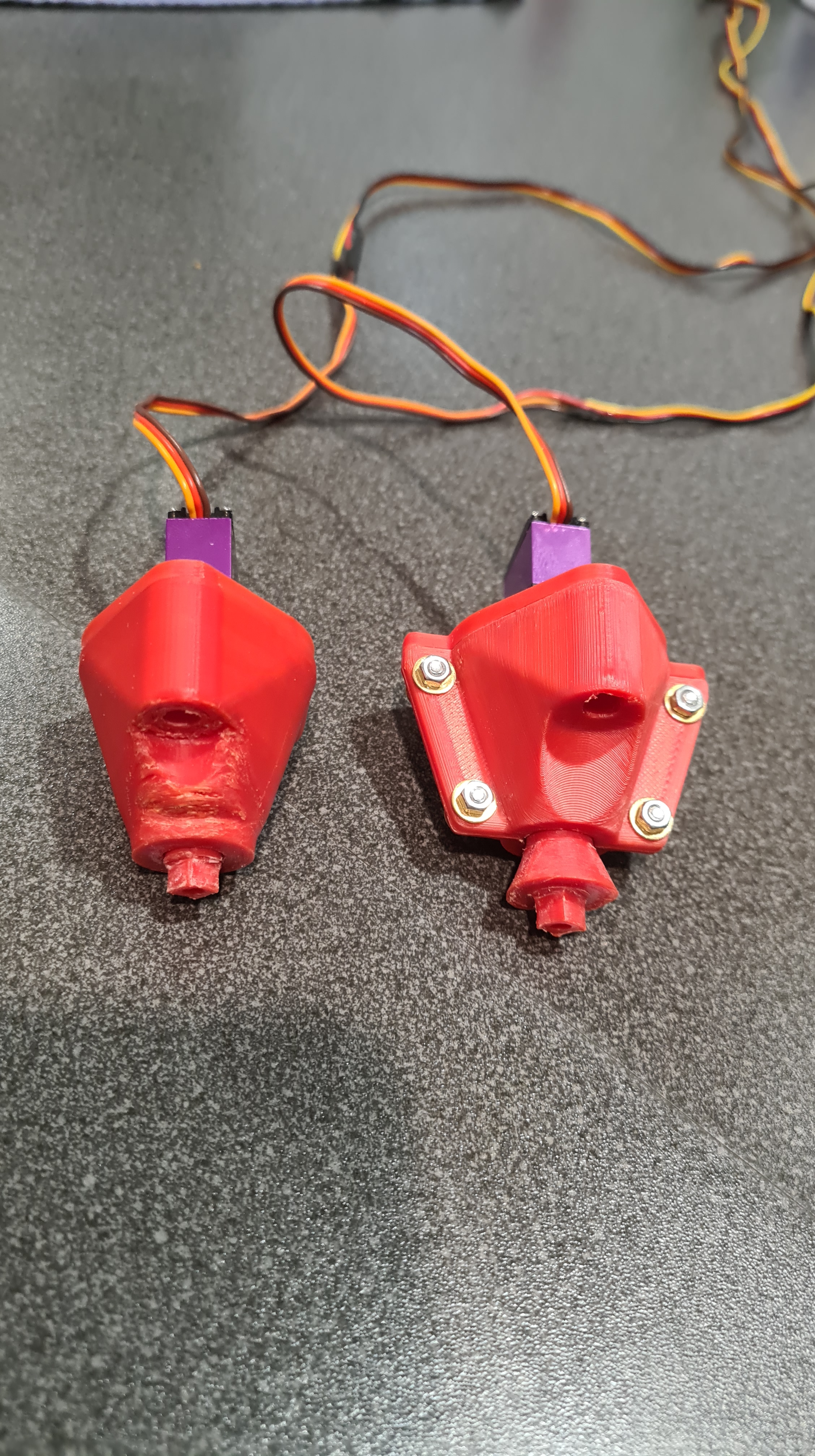

3D printer upgrade Mk II

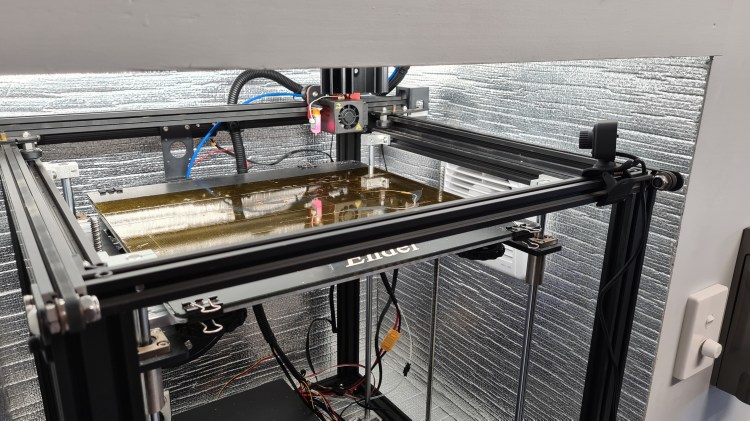

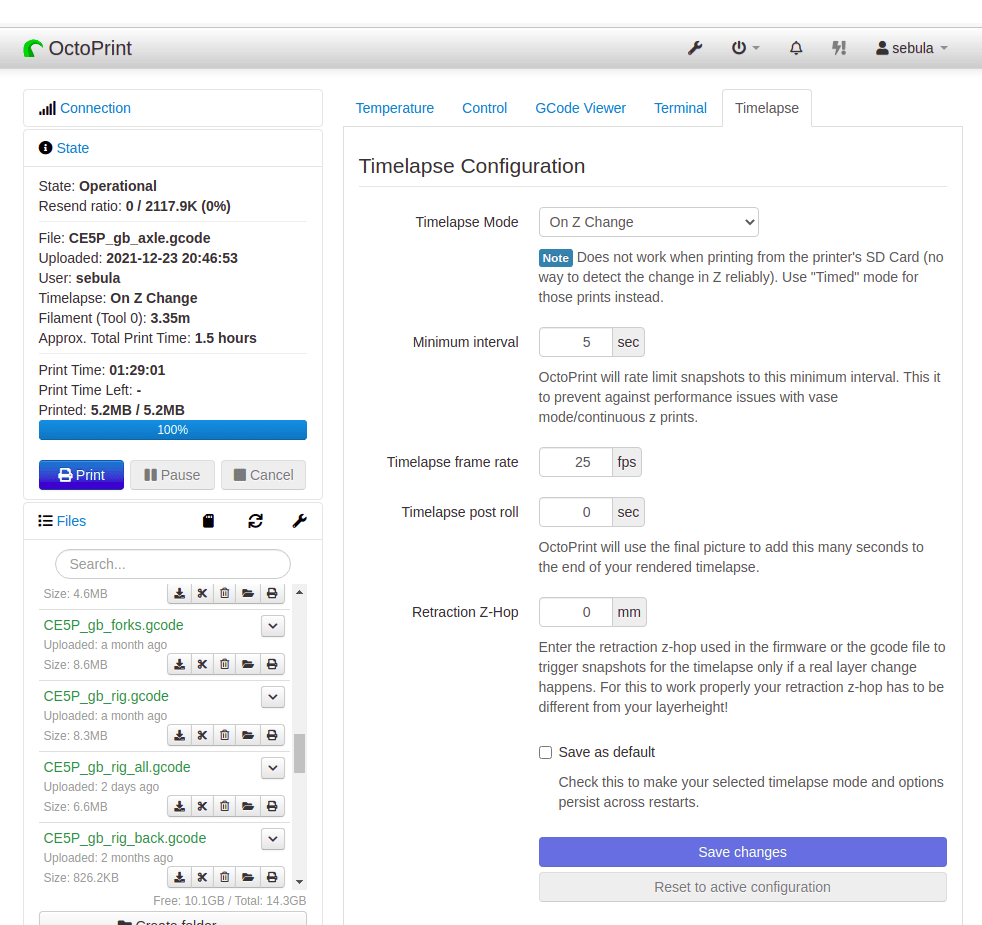

It’s been a while since we did some decent 3D printer upgrade – Last time Sebi introduced RaspberryPi to make our printing much more comfortable and now the time came when he pushed it to another level – a BONELK USB 1080P CLIP ON WEBCAM!

It came in a nice packaging.

And we had is set up in a just a few moments. Camera clipped on a printer frame and it’s USB connector straight to the RaspberryPi (see the top right corner).

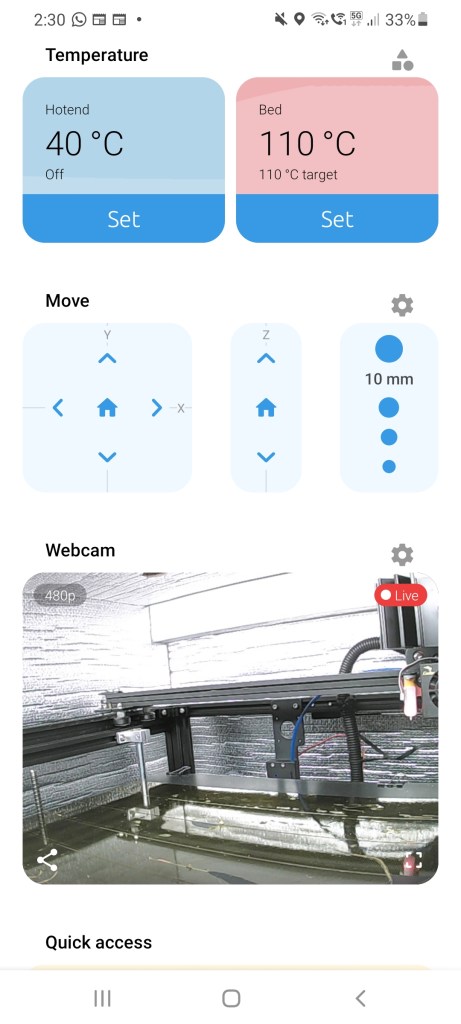

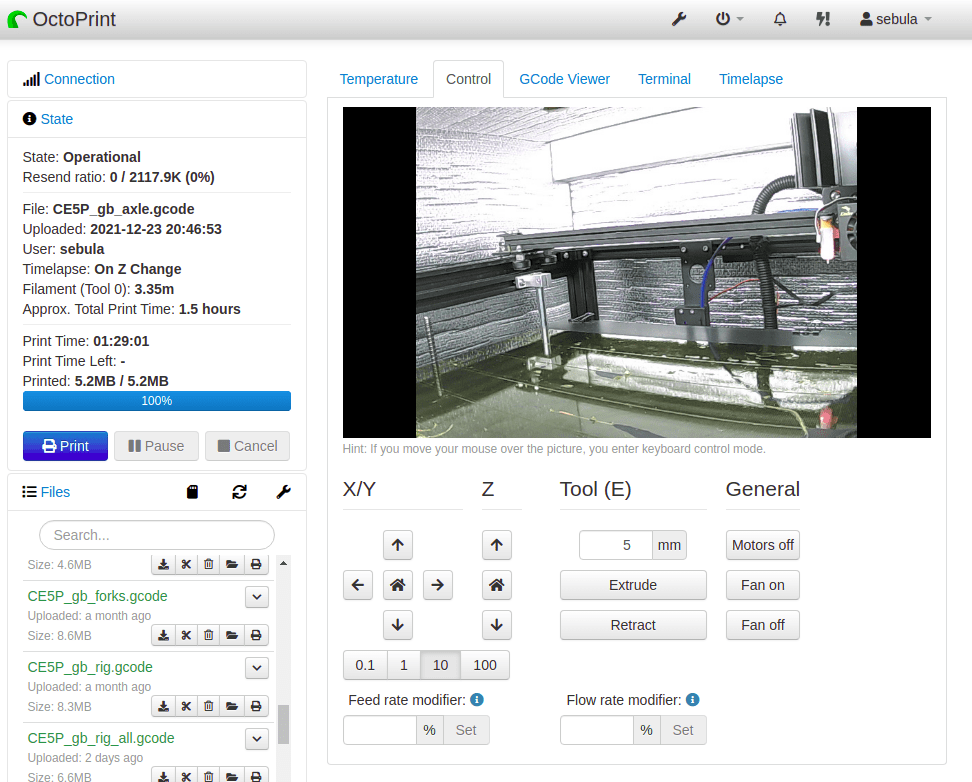

Camera’s been instantly recognised by the Octopi and even without any restart or refresh started providing a live stream from the printer. Picture below is a screen-shot of my mobile running a mobile version of the Octopi when printer is just heating up for another go.

Checking on the actual web interface – many more options came to life there.

Clearly the most tempting one was the Timelapse.

There are three Timelaps Modes – normal, Timed and On Z Change. We’ve tried both interesting ones the normal mode first.

As you can see it comes initially bit blurry and looks like a low quality. However at some stage I realised that there is a manual lenses focus which improved things a lot. Well seeing that one coming well, Sebi suggested to try that “On Z Change” mode – and that was the right one!

As you can see, video is much more entertaining, while clearly capturing all what’s needed. Thank you Sebi, this is awesome, I don’t need to get out of my sofa any more! 🙂

Gimbals redesigned

Latest test shown us some weaknesses in the gimbals design. The main one was that the axle was not strong enough to withstand number of forces and moments the controlling mechanism imposed.

For reference this is our “test” axle. You can see that there is not enough material in its narrowest part (at least not for our 3D printed ABS). Also the “head” doesn’t have too much surface to stick to the “fork” properly – so we actually had two event of a clean separation on that joint.

And now this is our new one. I’ve expanded the main part to get more strength (meat) there and added a conical head to get more surface for gluing to the fork. There is also a minor improvement to the lever installation shaft, but just a tiny fix there to fit better.

The gearbox cover also came with a substantial change as my main problem was that it wasn’t properly serviceable. E.g. if the level screw got loose, I would have to re-print the whole thing as the axle was already glued in the fork.

Sebi says it is an overkill, but I split that gearbox in two parts which is now properly bolted together. While it is now not obvious, this also gave me an option to print those parts vertically, which comes with much smoother result.

.. and finally – all mounted again. Looks pretty cool, doesn’t it?

Now three more to go … plus spares!

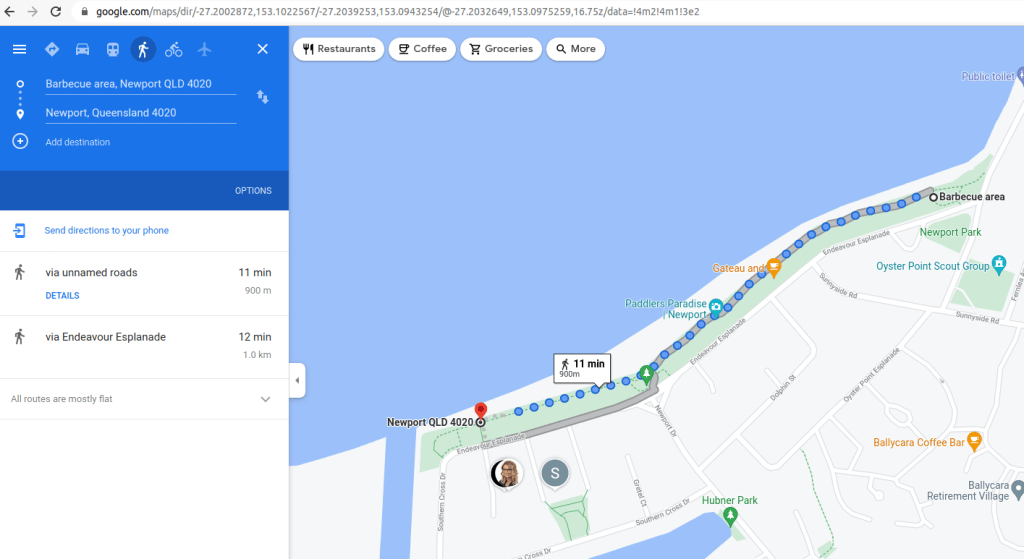

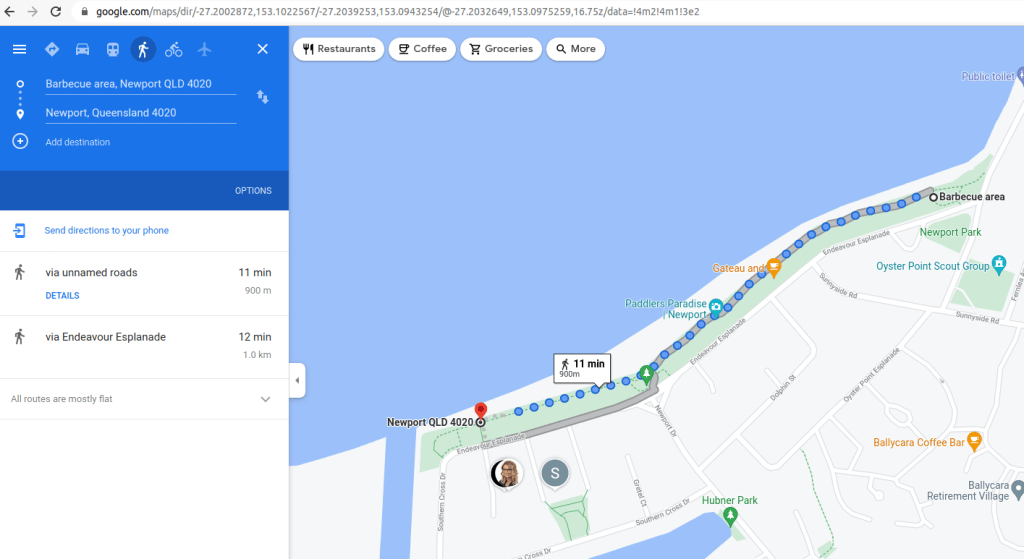

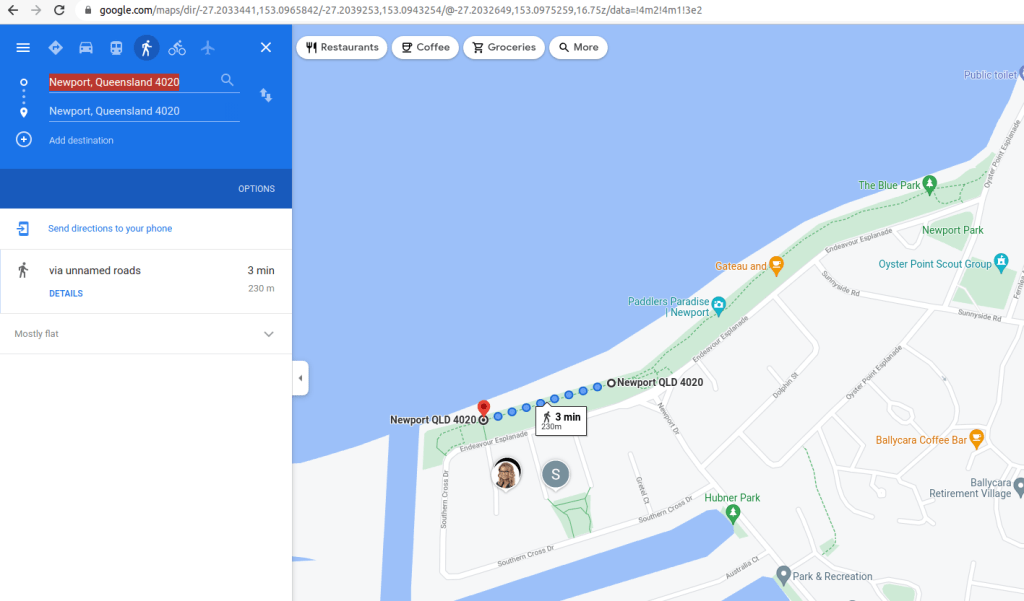

Test #2 report – we made it!

As per our yesterday’s article, all has been prepared and star constellations were favourable so I grabbed boys (Sebi, Jacob and Oli) to the shore to repeat our previous test – get our jet-cart to the Blue park and back (nearly 2km ride).

Map with our trip below.

Weather was much better than through our first trial – as you can see we’ve got 11km/h (3 knots) cross-wind to tackle.

I took evidence of our test by taking a picture of Jacob’s watch – it was 8:10 am morning when we started.

And we have a lift off! 🙂

I took multiple videos of Sebi steering the cart on the pavement, but it’s tilt in combination with that cross wind was giving him a hard time.

And at the end we made it – I took a video when reaching the Blue park!

By that time there were already few defects:

- Front-right gimbal lost as its axle broke due too much stress and material fatigue

- Rear-right gimbal lost as propeller lost its all blades – no idea how that happened, very likely some of its dislocation

- Finally we’ve lost left vector-thruster – due to a loose screw

Interestingly, even after loosing 2 gimbals and one vector – Sebi’s been able to keep steering it all the way back! I think it was a coincidence of a cross-wind coming from a starboard and actually absence of those gimbals on the right side, but Sebi did one of the longest stretches there. I think it was more than 200m, while I’ve been able to take a shot of its shorter half.

And that’s it! We’ve discussed the outcome with Sebi and he was much more pleased than with our first test. Clearly the problem was that gimbals’ orientation was unison and he couldn’t use those in some more convenient way. Also covering all that distance and making it back – so satisfying.

Another big win was the battery – real hero of our test. Our battery made it all the way there and back and still remained sort of 60% full (min 17.4V, max is 25.1V).

There were clearly few lessons learned:

- We need a pre-launch checklist to be able to prevent some of those problems we encountered like that loosen screw on a vector:

– check all screws on vectors

– check all screws on gimbals

– check that batteries are properly attached and not loose

– check that all batteries are fully charged (Main, Arduino, Servos, Remote) - Commence a dry-run on all features

– Remote connects

– Both front motors turn and in a proper direction (which generates thrust)

– Both vector-thrusters operate

– All 4 gimbals are responsive and can move in all directions obeying commands from remote

– All 4 gimbals motors can are responsive and rotate in a proper direction (which generates thrust) - We need to carry some minimal tools with us:

– Thin pliers

– Phillips screwdrivew

– Duct-tape

– Scissors

– Multi-meter

– Replacement batteries (Main, Arduino, Servos, Remote)

– Gimbal wrench - Replacement parts to be stocked up:

– Have a spare propellers at least each clockwise and counter-clocwise

– Have a spare gimbal (2)

– Have a spare servo (2)

– Have a spare motor (1 main and 1 gimbal each)

– Have a spare intake

– Have a spare vectoring thrust - Design changes

– Make gimbal axles more robust

– Make gimbal gearbox serviceable

– Make axle-fork joint more robust (currently just glued, but probably not enough surface there)

Well, just that re-design of gimbals and stocking up on those spares will take us couple weeks. But I am sure it is worth it and while it looks like a chunk of work, it is much easier now when that initial design is already in place. So let’s get back to work!

I hope you had some fun, as always please let me know your comments / ideas, it is always awesome to get some feedback from all of you. Meanwhile, stay tuned! 🙂

Big preparations

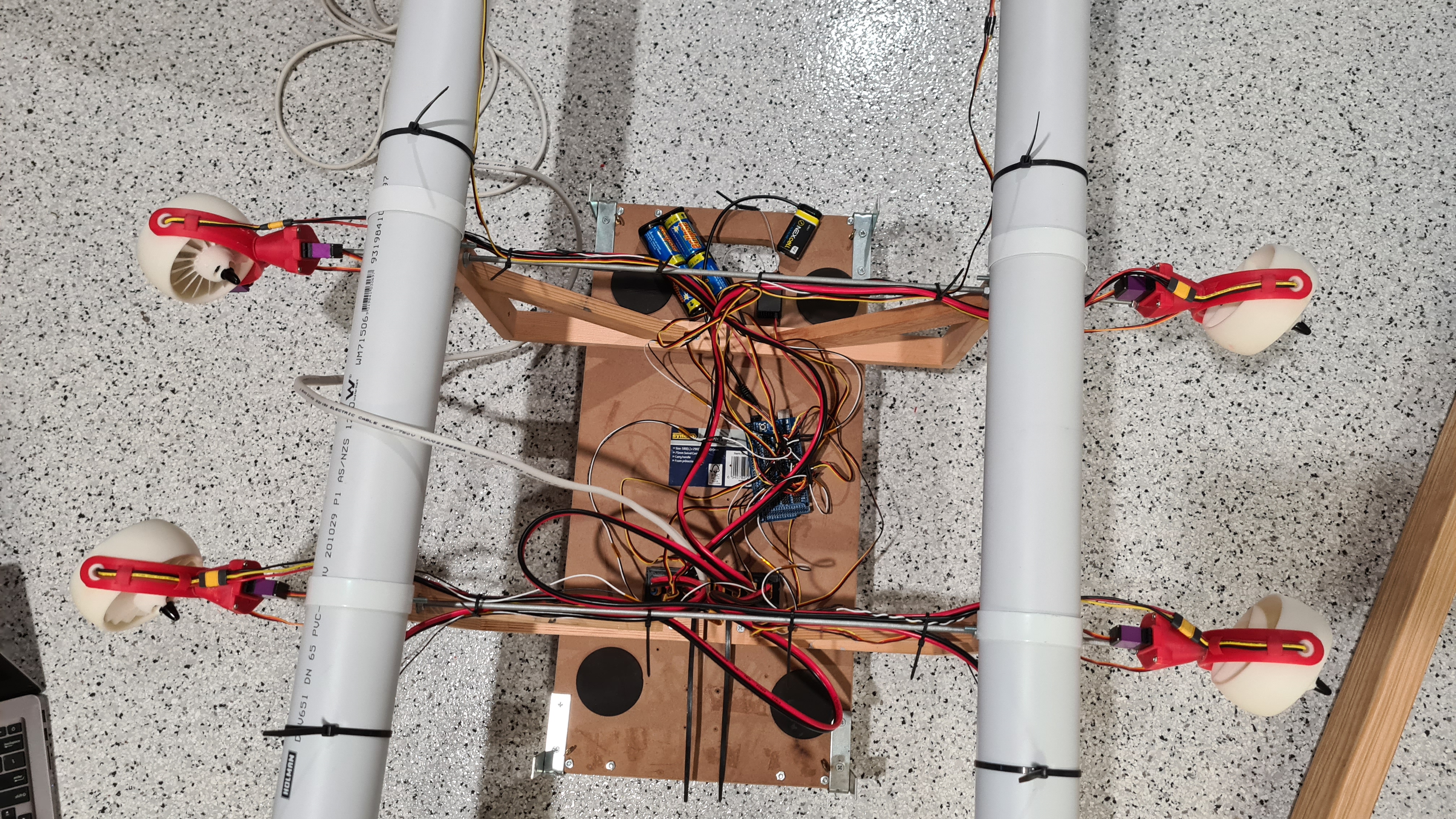

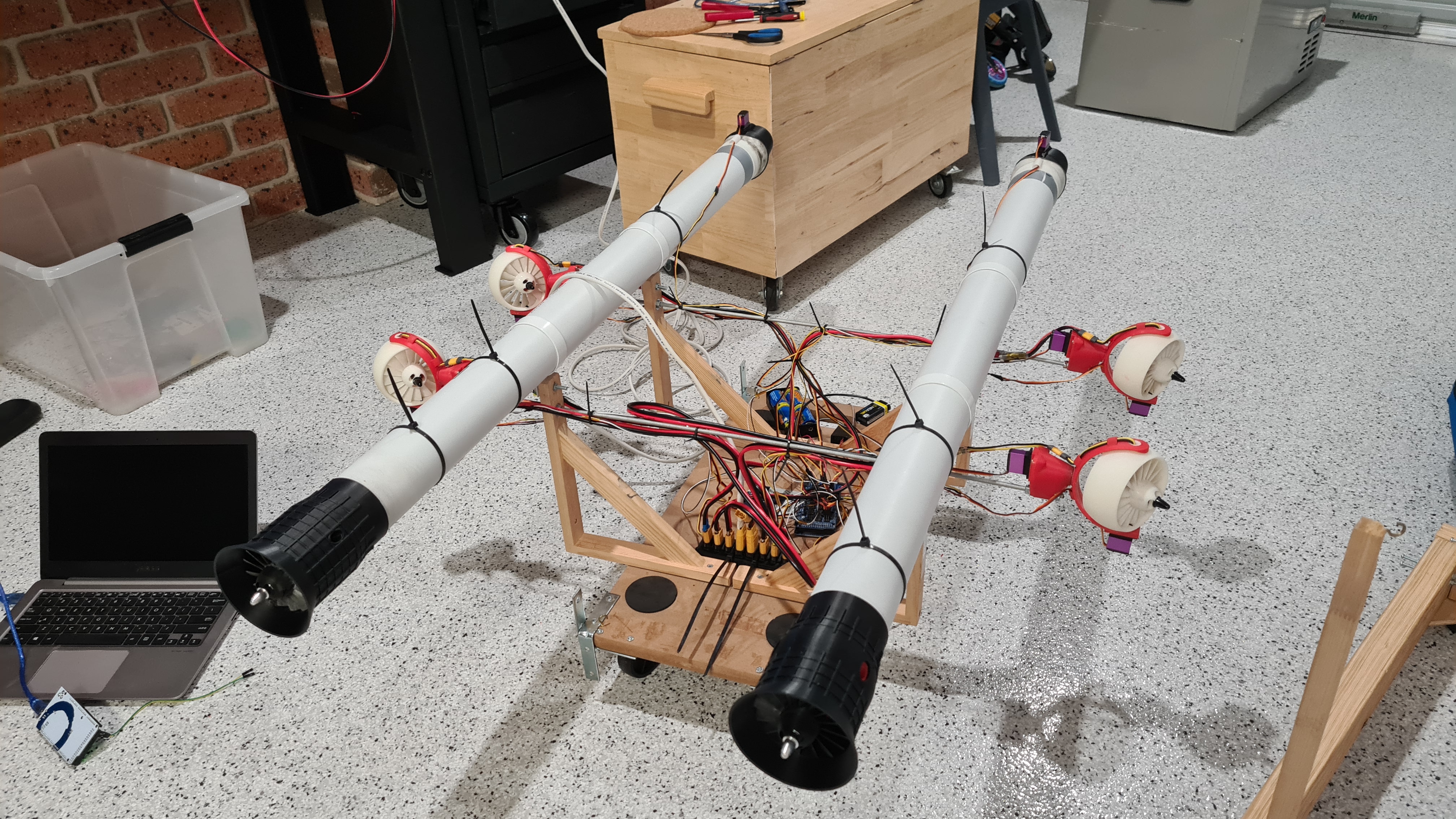

We’ve spent practically whole weekend on getting things ready for the main goal of our Phase 3.

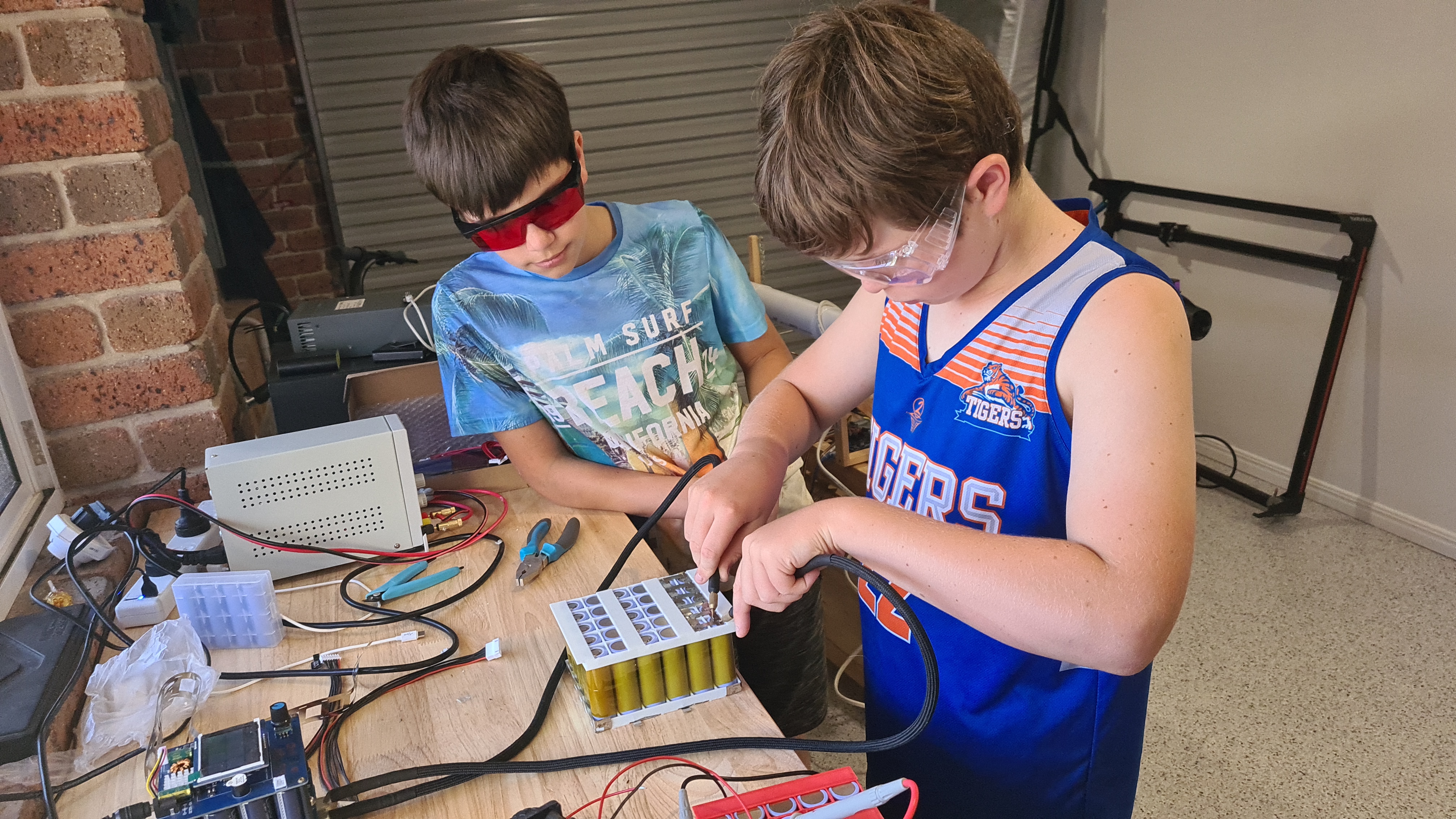

And when I say we – we actually had a great help from Jacob, who visited us here in Newport. He did lots of soldering and calibration work on ESCs.

To wrap up Saturday I asked Jacob to give us a bit of overview on what’s working now.

We’ve kept pushing almost whole Sunday where it involved even more cabling, soldering and calibration. Sebi got bit tired, but didn’t give up.

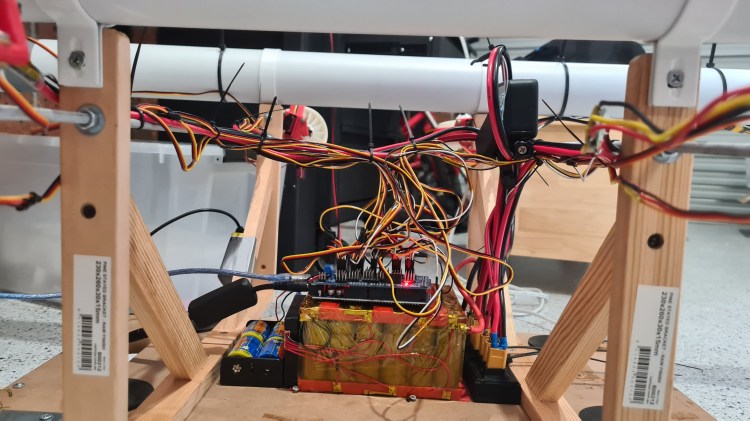

I took few more pictures just to give you a tiny idea how that cabling looks like now, I am getting pretty amazed about all that stuff myself.

It wouldn’t be that satisfying without giving it a try, agreed? So here is Sebi, demonstrating when it all works together – thursters, vectors, gimbals – all remote controlled, while connected to our 2kW power source. 🙂

I hope you find it so cool as I do and I can’t wait to get it out for a proper ride again.

Battery pack evaluation

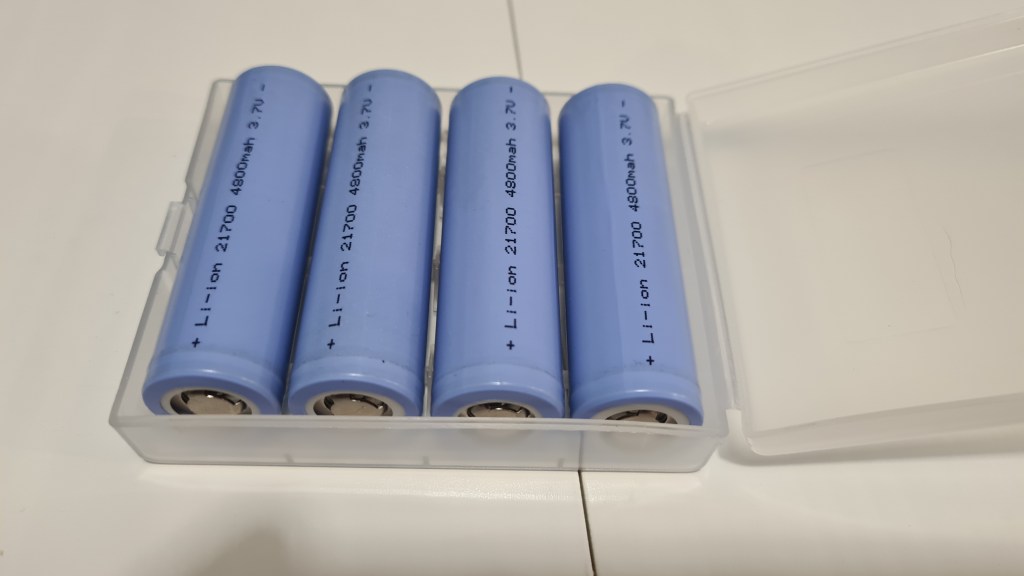

As you will see, I’ve labeled our battery packs A & B, just to have some easy recognition for those when charging etc. I brought Risa the battery pack B as he agreed to test those battery packs for us. So all his findings below & huge thanks!!

Battery pack A – tested 10/12/2020 – 16/12/2020

Risa’s comments:

BMS was cutting out at I think ~17.4V

/6 = 2.9V per cell

full charge cut out at 25V

/6 = 4.166V

18.46Ahr / 5 = 3.69Hhr per cell

Battery pack B – tested 25/11/2020 – 30/11/2020

Risa’s comments:

BMS was cutting out at I think ~17.4V

/6 = 2.9V per cell

full charge cut out at 25V

/6 = 4.166V

17.6Ahr / 5 = 3.52Hhr per cell

Results

| Battery pack A | Battery pack B | Sum | |

| Test length | 27h 1m | 28h 09m | N/A |

| Ah max | 18.46Ah | 17.63Ah | 36.09Ah |

| Wh max | 402.38Wh | 384.23Wh | 786.61Wh |

| Ah per cell | 3.69Ah | 3.52Ah | |

| Weight | 2.487kg | 2.487kg | 4.974kg |

Having both batteries ready we should be now handling quite reasonable 36Ah. Provided that I estimate peak consumption to be 40A, we should be able to go up to 50 minutes full speed with our Jet-cart now! Let’s say that we’ll go 1/2 power average, we can probably go for almost 2 hrs.

I think this is a good start and reasonable promise that we’ll be able to put together enough power (with reasonable power/weight ratio) to make it to another stage!

I’ve asked Risa to provide his summary on all this, so take this paragraph as a placeholder for Risa’s epilogue. 😉

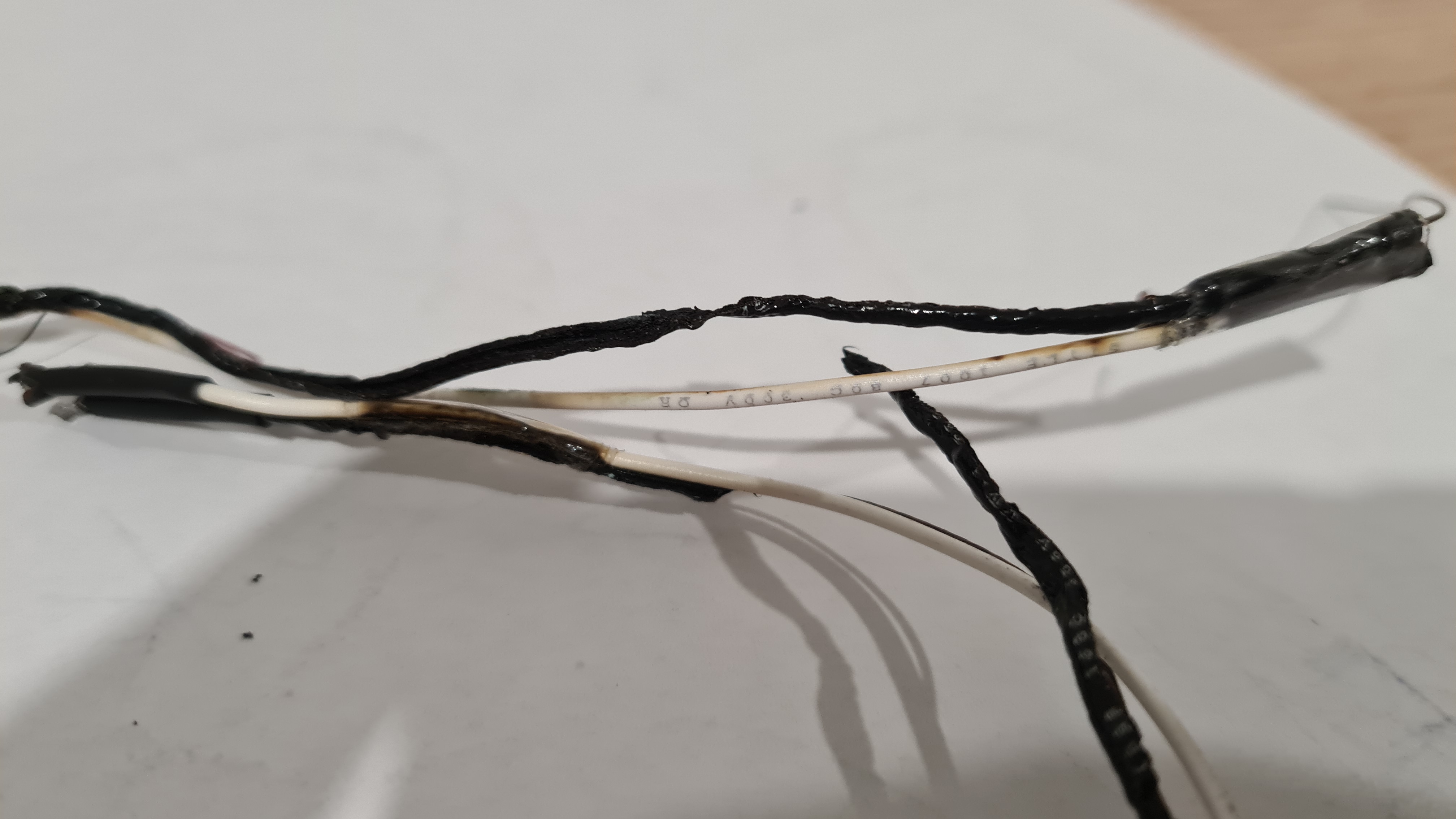

Power bridge MK II

Well, there’s been an accident. Quite a serious one. When we’ve been trying to test some higher powers for our motors – signal cables to our ESCs burned out.

Interestingly, as you can see on pictures above, only the ground cable combusted. The signal cable seem to be ok.

I’ve obviously started thinking where things went wrong and as tried to measure current going trough our power bridge we noticed that part of it burned out / short-cut-ed as well (unfortunately I haven’t taken a picture). Discussing all that story with Risa and Bernard they made me to draw them a diagram first.

Not sure it it makes any sense, but battery is in a bottom left corner and current is distributed through our Power Bridge to both ESCs, which then control Motors. There are also signal cables going between ESCs and our brain-Arduino.

As wrote above, showing this to Risa and Bernard, I’ve ended up with following update.

There’s been probably lots of current running through a whole system, which was too much for our PCB-based Power Bridge. The big red X shows where our power connector disconnected from PCB and caused a current redirection. Instead of going through the wire “7” it released power through other grounded cables 3->5. And as those were too thin they … combusted.

So the first step to tackle this was a complete rewiring of all high-power cables (25A).

Second part of the plan was our power bridge re-design. Sebi cut off all the PCB material and soldered in some serious copper wires.

It all obviously didn’t fit in our old case, so bit of printing was needed as well.

And 3 weeks later we are where we’ve started! 😀 Hopefully it will work out now.

Gimbal audio spectral analysis

I’ve got some excellent feedback on our latest article Spoilers! from Chris on our internal chat (Discord) where he came with following comment:

I must admit that I closed my eyes when the RPM ramped up at the end, expecting to see a plastic shower! Oh yeah… and do you happen to know the RPM they spin up to?

Chris Drake

… while he instantly followed on that with his typical call for action and got a spectrum analyzer to check that RPM from the video using the Spectral View application. Output out of it surpassed all my expectations, that result looked … colorful.

Luckily Chris immediately provided his commentary – “Most of the test was at 3700hz, ending with a ramp-up to 5200hz (that’s the strongest of all the harmonics anyhow) – not sure if that’s the motor speed, or the rate at which the blades pass by. Multiple those out, and if it’s near 5000 – that’s the motor speed. If it’s wrong by the number-of-blades, then I’ve picked up the wrong thing.”

Chris also noted that common phone Mic’s only can go up to around 20khz, and his phone has a max sample rate of 48khz (making it unable to record anything about 24khz at all), so it’s inconclusive as to what that line maxing out at 5200hz means (it might be a harmonic of something unrecordable).

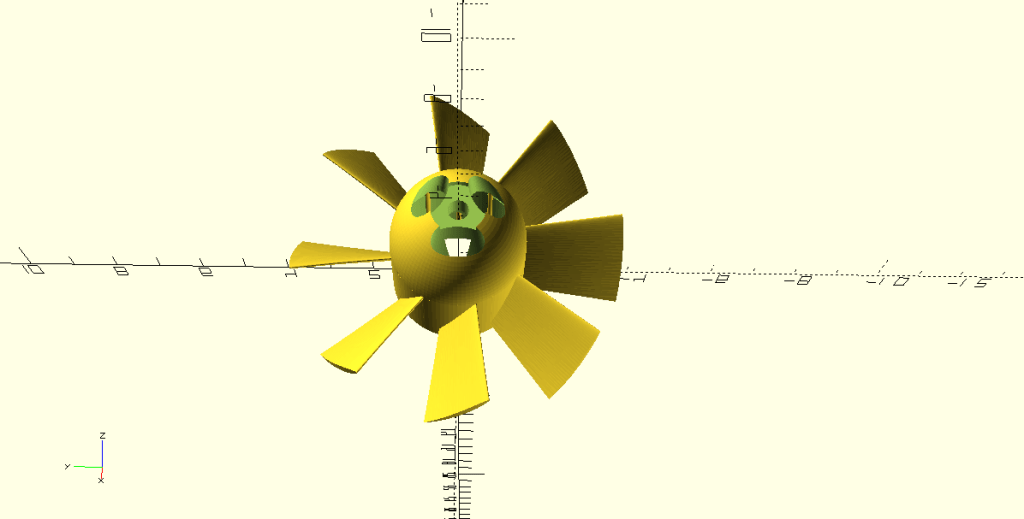

Of course he also came with some cool suggestions for improvements. For the reference, this is how our propeller looks like today (Chris’ rendering).

.. and now this is a how the most efficient for 2kg (20N) at 20,000 rpm should look like based on his calculations.

While they look quite different, you can see that that “pitch” is not that different. Luckily Chris confirmed that with:

… which is actually pretty close to what you’ve got.

Chris Drake

Thank you Chris! Glad that we are not completely off the scale with this! And I clearly learned something new. 🙂

Spoilers!

It’s been bit busy in the office so I haven’t had a moment to finish any of those “in progress” articles, but today we made with Sebi some super cool test of our new gimbal so sharing at least that as a digest of what’s coming 😉

BMS Resistance

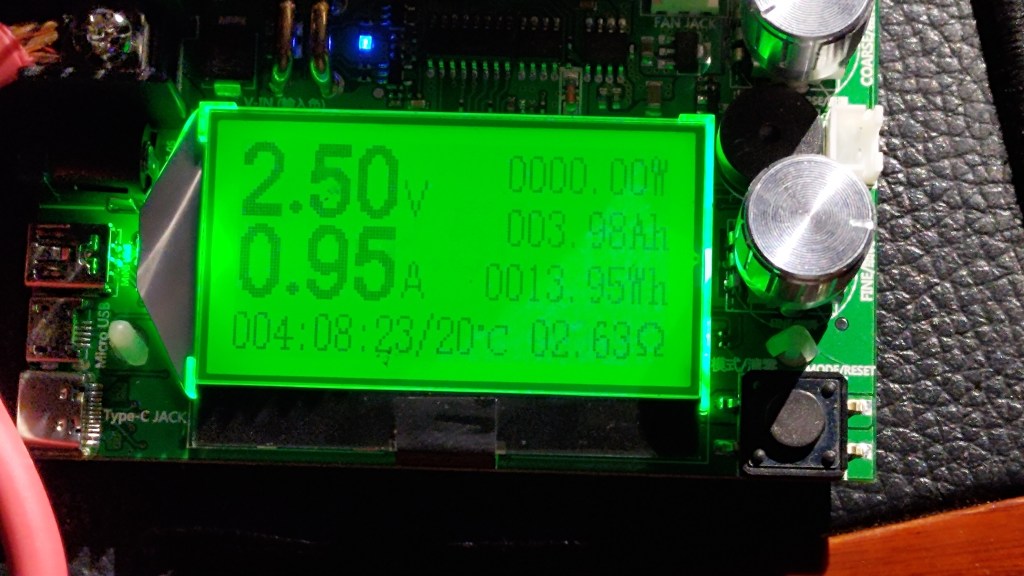

Some lessons are hard to learn. When working on the second battery I’ve got stacked on the step 4 – Make sure that the circuit is No Short.

Measuring the resistance between the BMS cables I should be getting values between 0.0-5 Ω (Ohm), but it was constantly returning something between 8-10Ω.

I even searched for the User Guide for our Multi-meter to check if I am measuring things properly!

Knowing a little about what I am measuring I’ve connected our BMS and it started warming up a bit, but not too much to get me worried. Quick answer to all this was – it is just balancing those cells in series! Well, balancing was a good idea, but when I measured everything again after 24hrs and it was still balancing it started not feeling right. Also the resistance wasn’t dropping, but rather growing. This really ruined my night thinking where I messed up and mainly if I could somehow burn our precious DALY BMS.

I’ve unplugged BMS and started with a cross-check:

- Battery voltage between its ends – 20.4V (tiny drop from yesterday) – OK

- Balancing cables properly connected in a right order – OK

- Voltage between each balancing cable ~3.6V – OK

- Connection with BMS – Looks stable

- No shorts – couldn’t find any

So help me to find two differences! Except the obvious – they are same … unless

… checking a voltage on the first one shows 25.2V and the second one -25.2!!!! Well it took us 15 minutes to rewire everything and solder it together again, but all good now – working resistance is down to 0.2Ω.

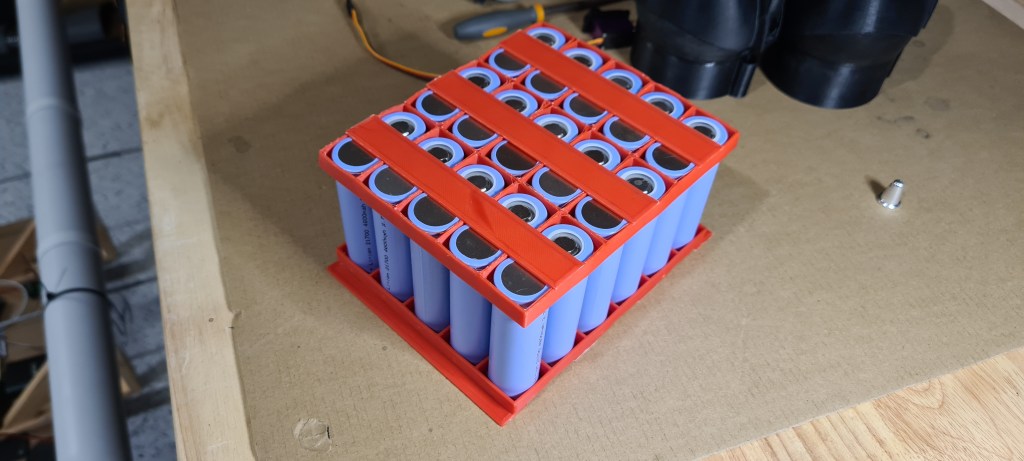

So after some wrapping we ended up with two (almost identical) super-cool power packs. 🙂

As always, let us know what you think, all comments and ideas are welcome! There has been already a note from Vlada to come up with some case for those to protect them from a mechanical damage – I think it is worth considering! But that’s for another day again.

First 100m

Sebi couldn’t resist and insisted on testing our latest setup straight on Sunday. Battery fully charged, connectors connected, motors tested, what can go wrong? 🙂

Considering some good testing place I decided that we’ll have no reservations and will be testing straight on a pavement going around our local shore. Sundays here are unfortunately making this spot favourable spots for ahem – Sunday walks, but who would worry about bit of audience. Also to get more support I called out for our local Redcliffe gang to provide us with some cover.

As you can see on a map above – our plan was to cover roughly 1km on a way there and back. However getting to the coast made me bit wonder about the actual weather conditions. So I checked BOM (Australian Bureau Of Meteorology) app on my mobile and took a screenshot.

Can you see that 22km/h wind there – combined with 24km/h gusts? It felt pretty much like that. Well, nothing like a bit of wind could turn us away from our plan. Sebi started warming up motors and also run his stop- watch.

And action!

Yep, one of vectors wasn’t mounted stiffly enough, but nothing what a bit of padding couldn’t fix. We’ve kept going! Luckily Robing kept taking more videos.

And the last one!

The last part is missing – the one when we lost a propeller. Anyway I think we’ve covered nice 100 meters before we had to stop for today.

I think that this is pretty result, taking that this was our first serious go and all those unforgiving weather conditions. Sebi wasn’t too happy, he’s been looking for more, but I think we did pretty well. We’ll make it happen next time! 🙂

Huge thanks for a full gang for support and see you soon on another attempt. 🙂

Make your own Battery pack – we have a battery pack! (part IV)

This is a direct continuation of my previous article Make your own Battery pack – spot welding fun, so if you haven’t read it, get there first or you’ll be missing lots of context.

We’ve left of when most of welding was already done and while we instantly jumped on a battery wrapping an wiring I still needed to do a bit of review of all material we’ve been able to collect to progress further.

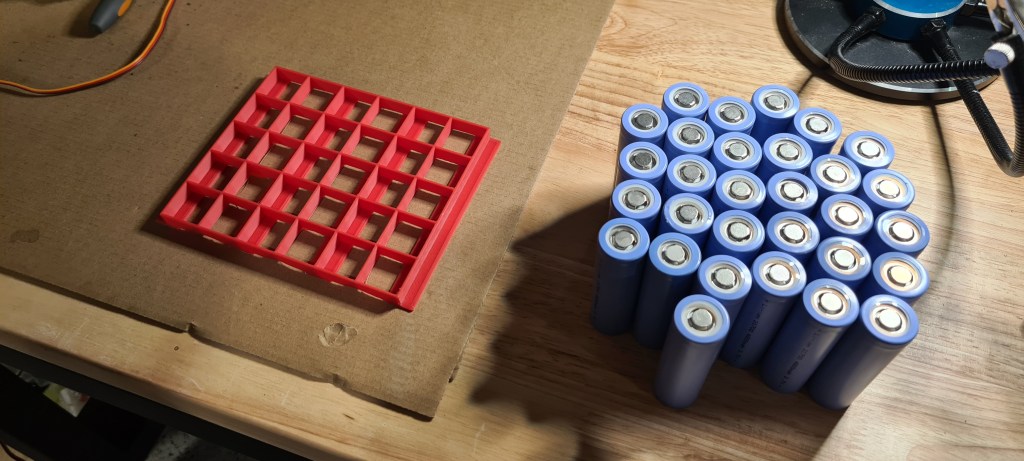

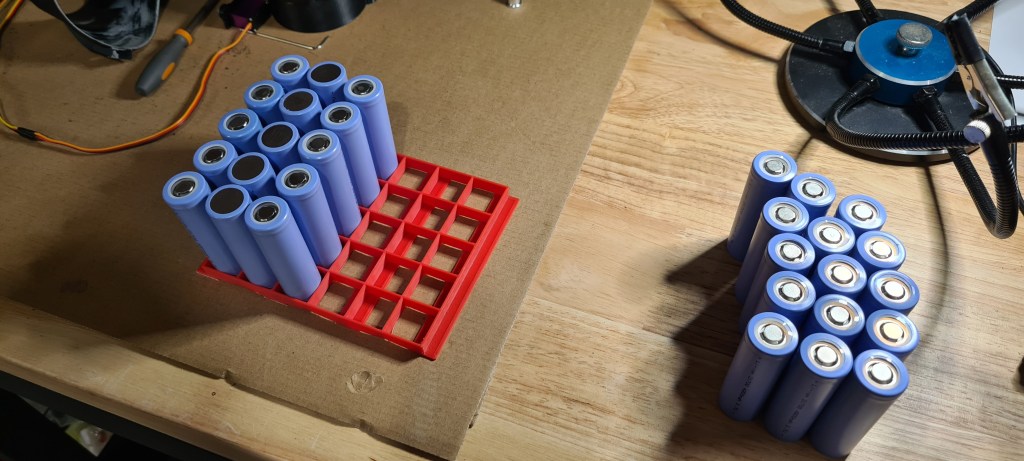

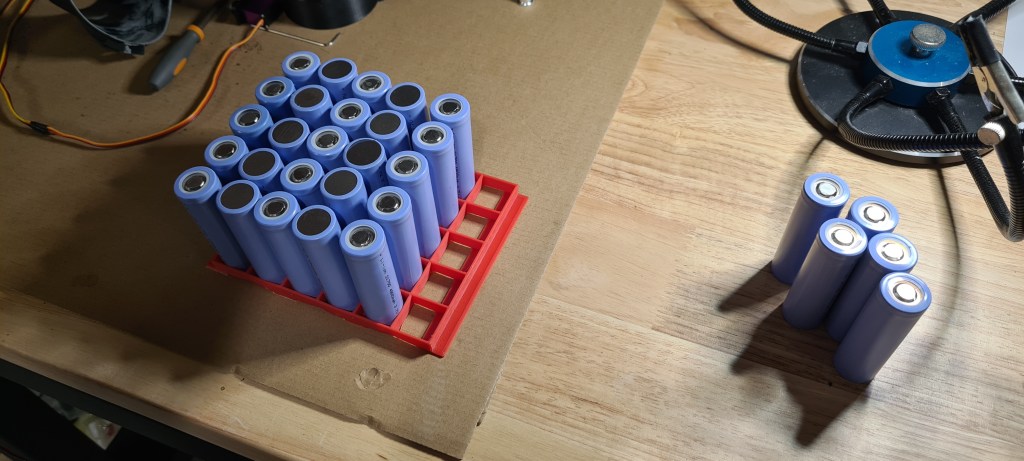

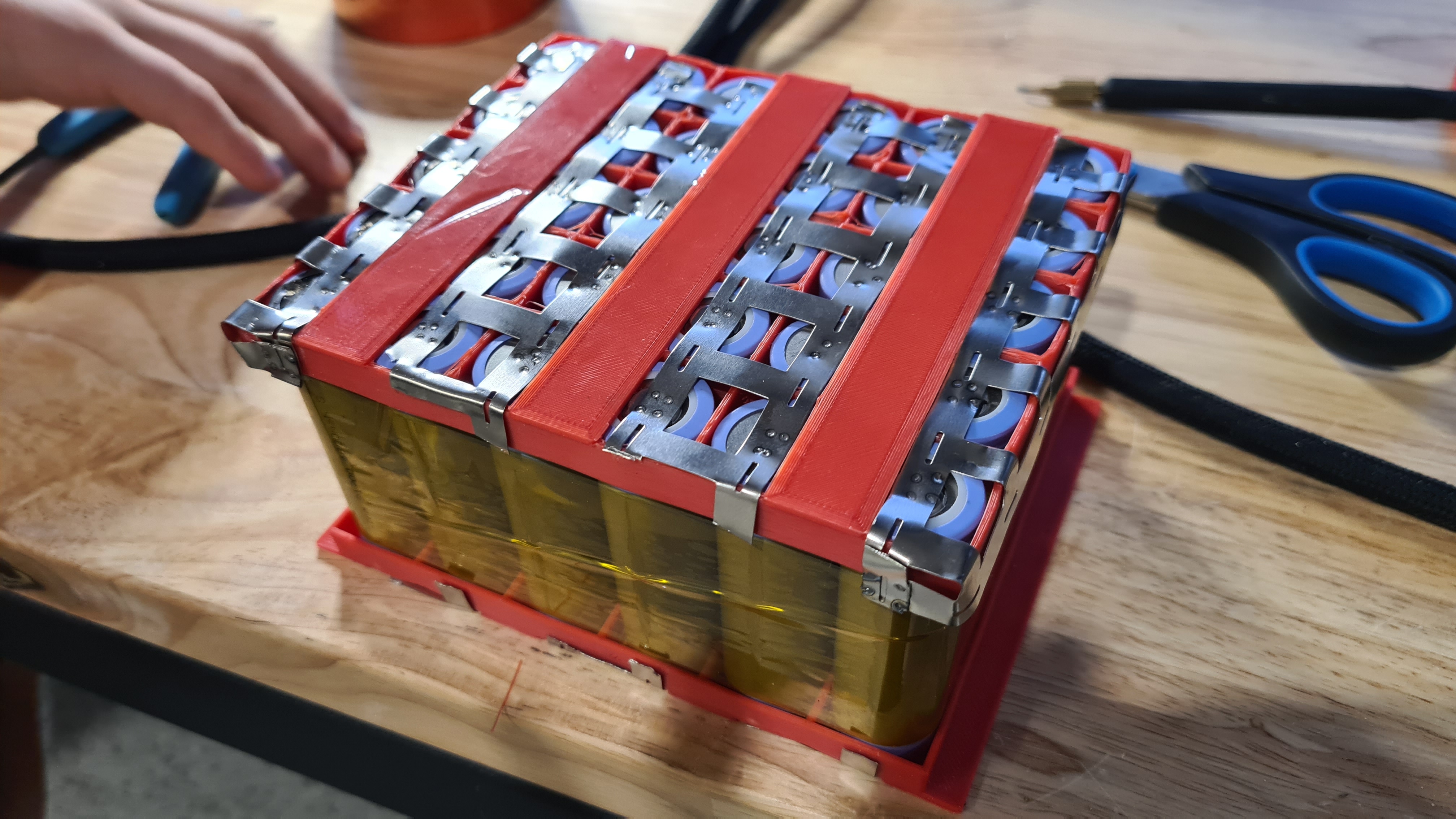

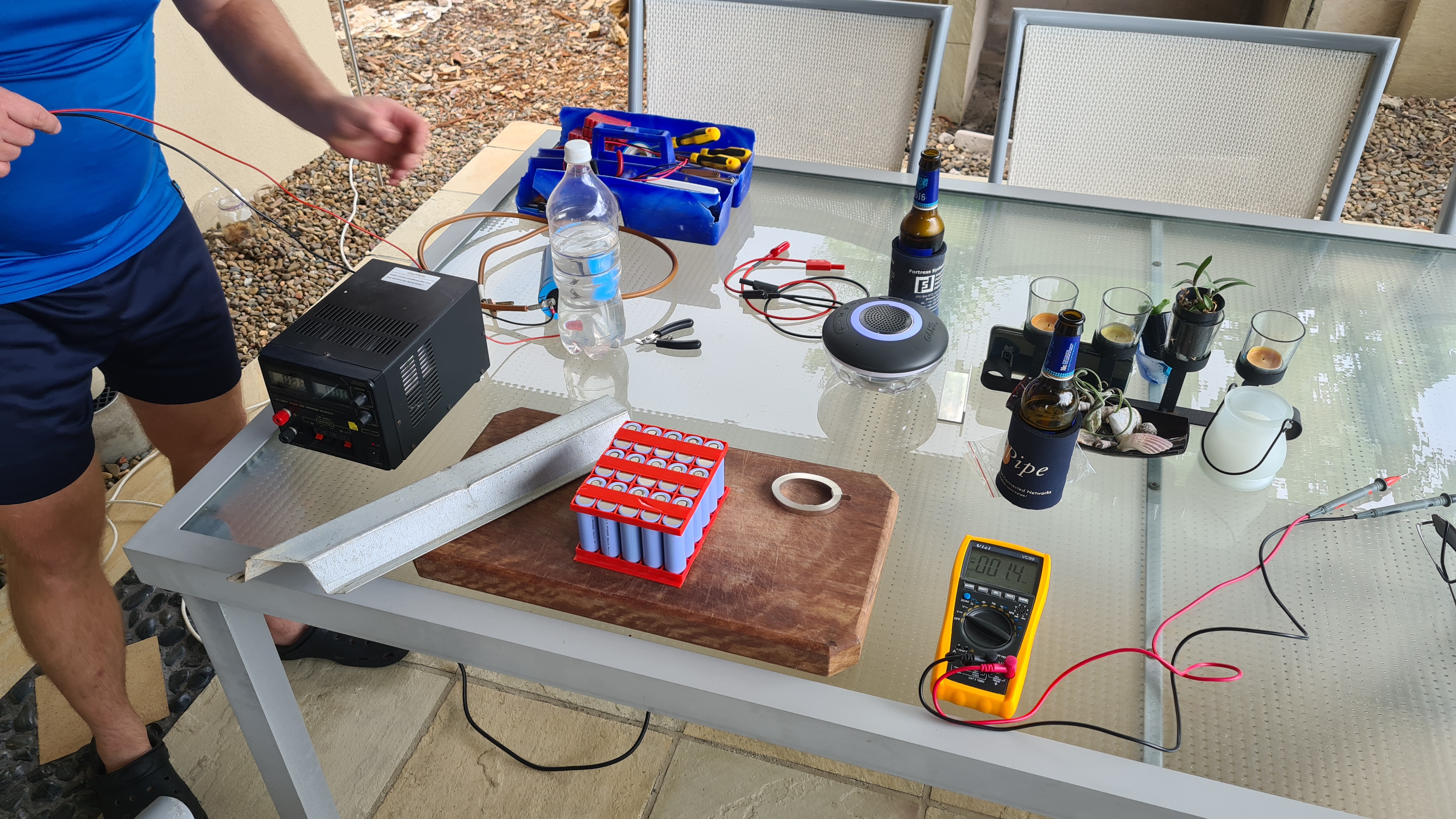

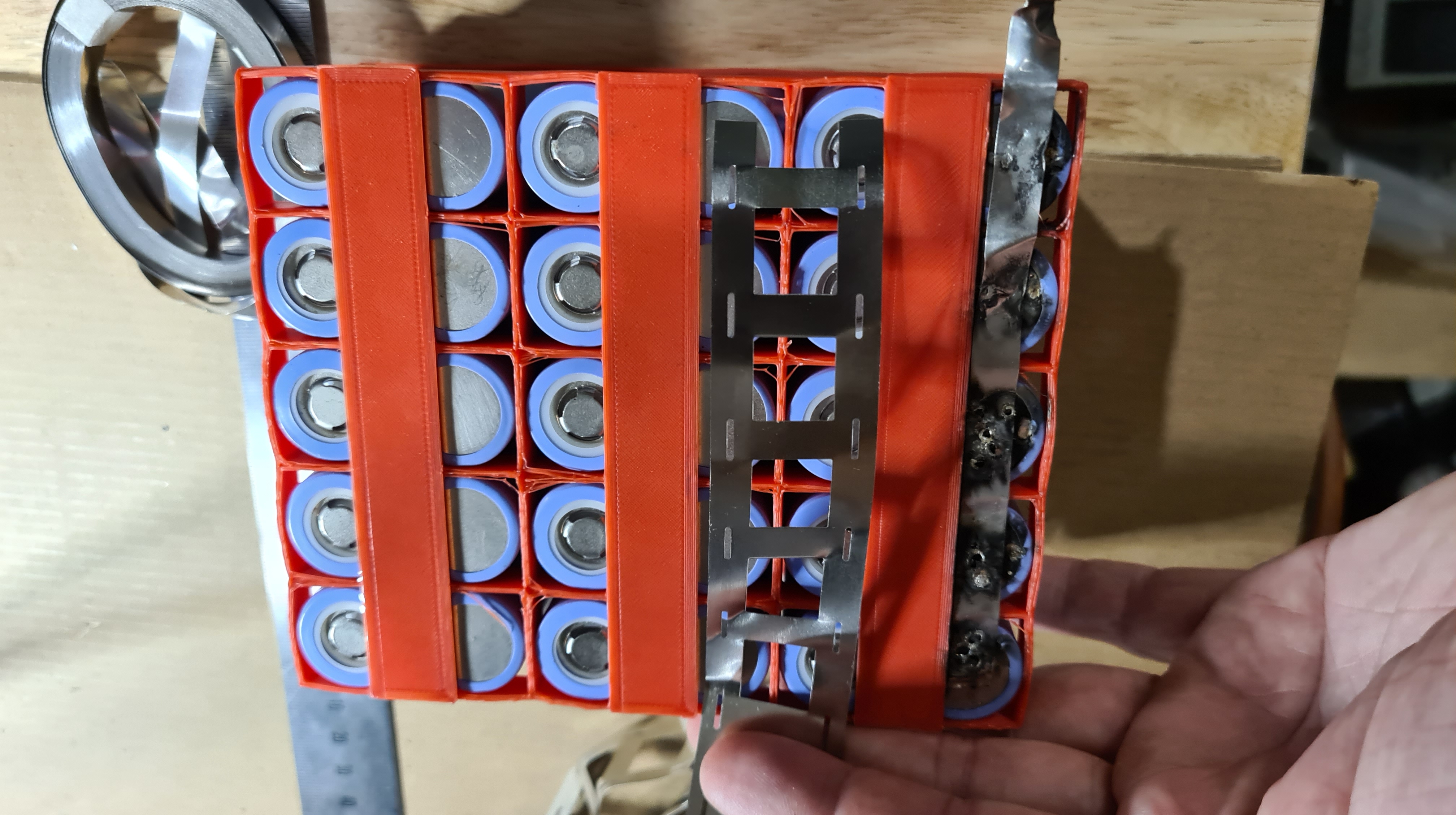

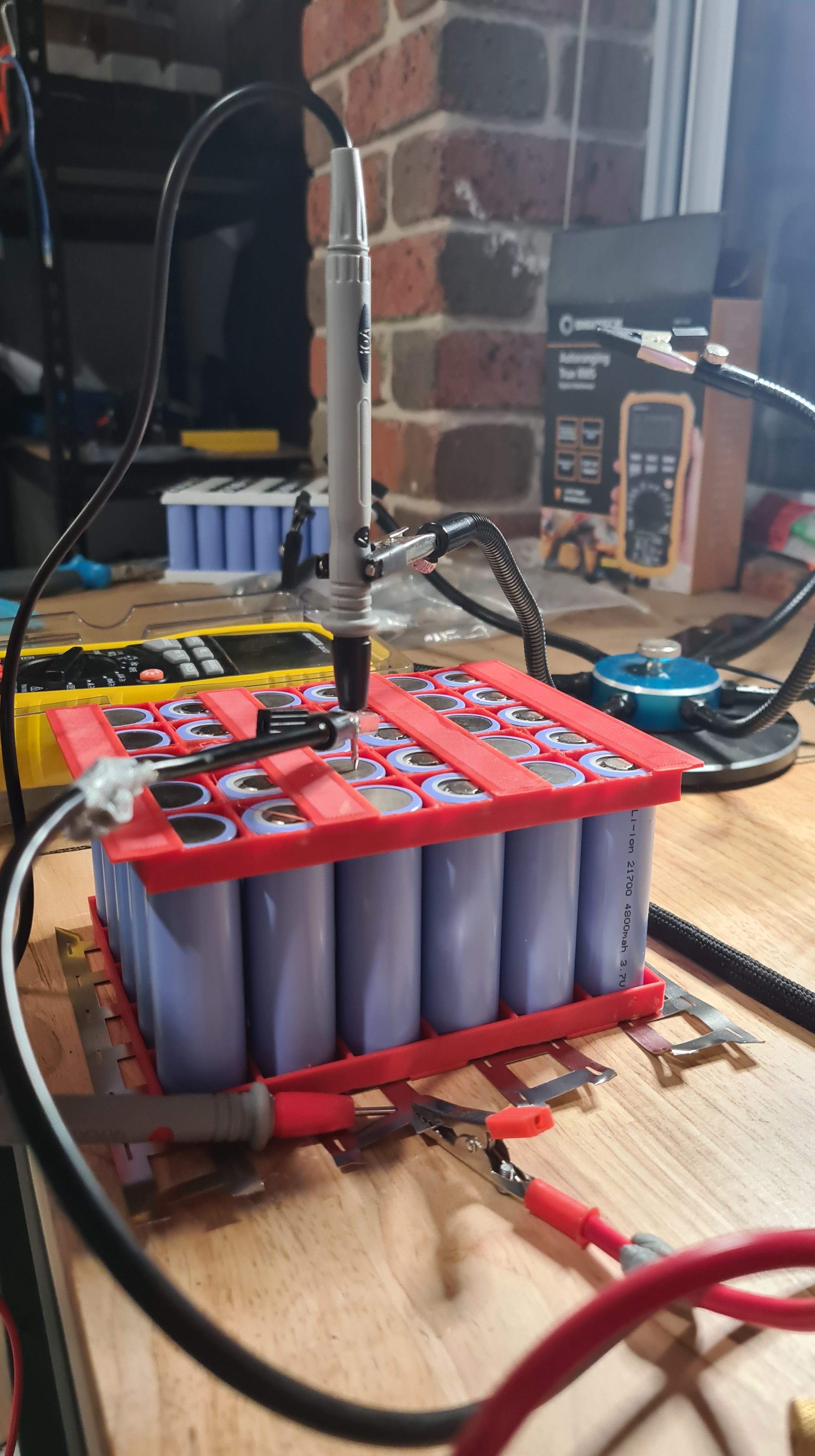

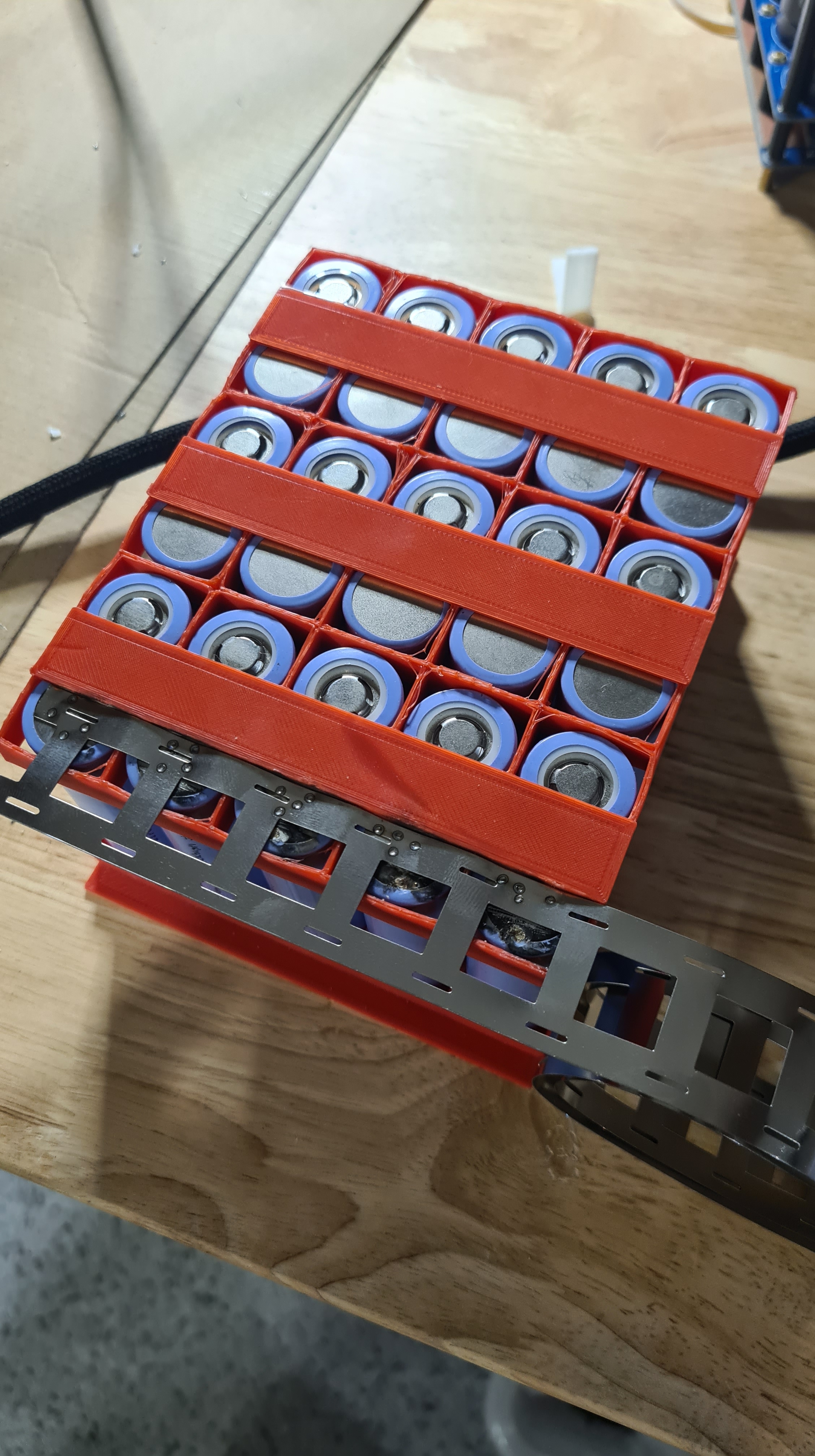

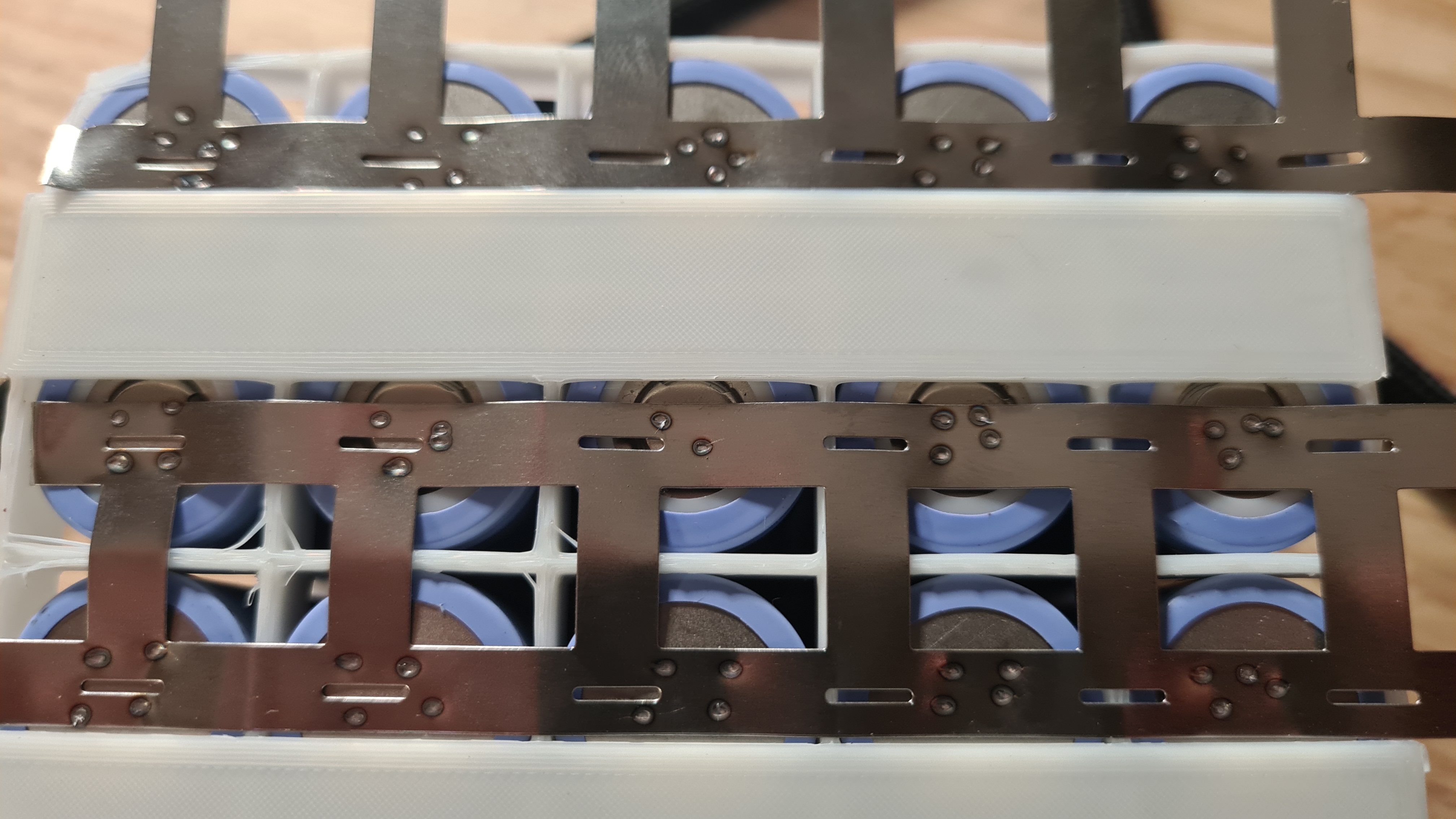

On the picture above you see two main (to be) battery packs in their racks. That makes two-times 6×5 battery cells + 4 spare ones. There are three packs of 2C Nickel strips, two 6S balancing cables and two male XT90 connectors. There is also a box with two 6S 30A DALY BMSs (Battery Management System), which came from China through Fedex and just getting them to my hands would be a story on its own.

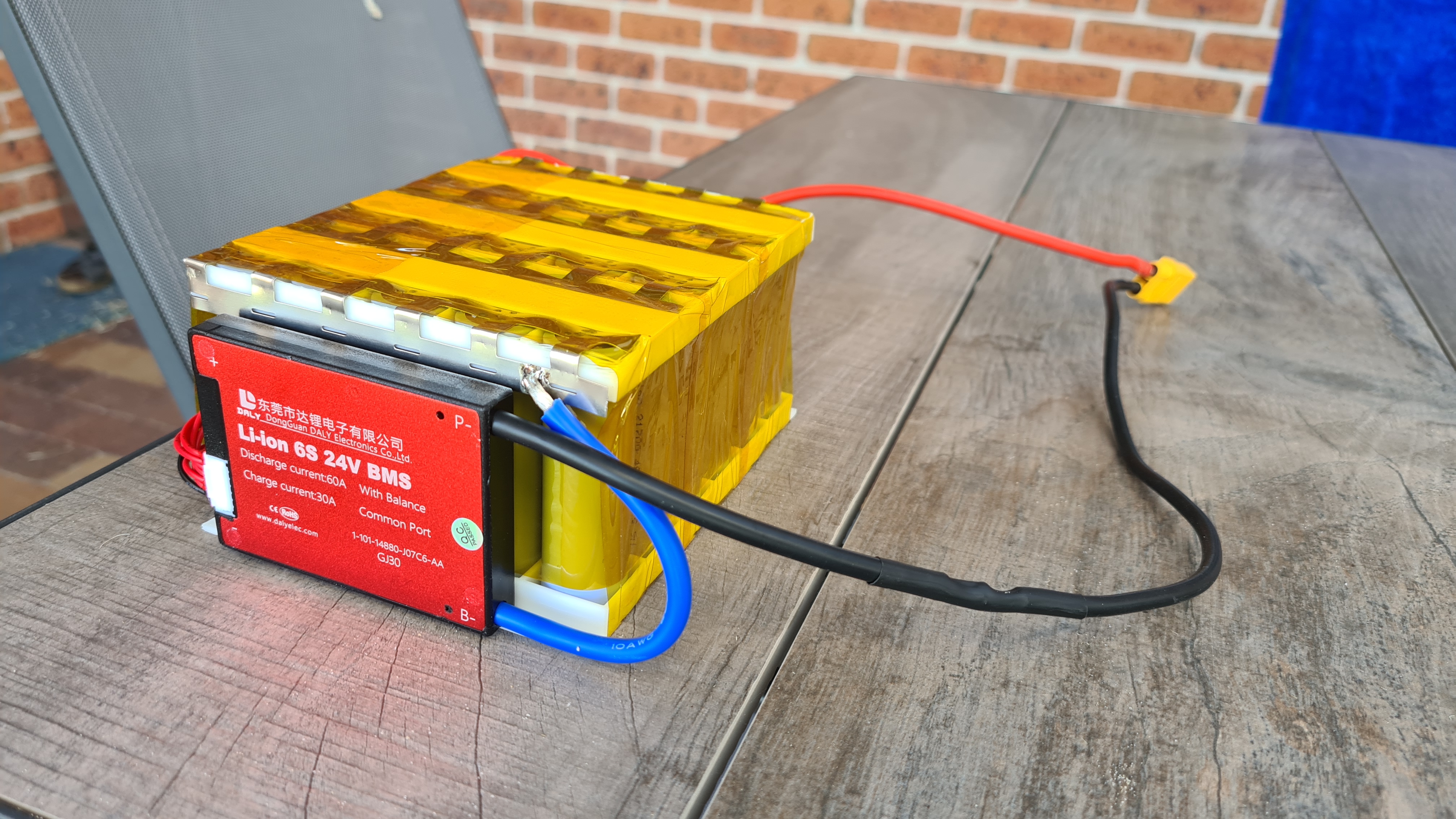

BMS above is a clearly a hero of our today’s story. Our current situation is that we have one completely welded battery pack, but it still needs proper wrapping and needs to be connected to the BMS. Let’s start with wrapping. One layer of Kapton did a job to make it more look compact.

Wiring next. Wiring instructions are bit cryptic, but pictures are sort of self explaining.

So it is simple .. just connect all cells in parallel sets to its relevant cable and don’t mess up! How about this? Actually I’ve learned a lot – mostly that when it is all coming to life you are starting to deal with some interesting currents here. There were couple times more sparks than what I would like and also got buzzed once from that welder.

I have just a little idea what I am measuring here, but Vlada says it is a working-resistance. It needs to be between 0 and 5Ω and it says 0.2. I think we are fine. I used a bit of Velcro to strap that BMS to the battery.

Last bit was more Kapton wrapping. Looks beautiful, doesn’t it?

Being super happy, I also took a video to show off with our master-piece. 😉

Next stage – darn how could you exactly charge this thing? Luckily once you have some reasonable BMS there, things are getting pretty easy – just connect it to some reliable PSU and BMS will take care of rest.

It took couple hours, so Sebi setup a tiny monitoring set.

And here is our IT guru monitoring the charging itself from the comfort of our kitchen.

I don’t have a picture showing how that battery pack looks all charged, but our multi-meter was reporting some 25.2V. Still took a last shot, putting our final product on scales to check how we are doing weight-wise – reading pretty much 2.5kg on the dot.

This was one seriously productive weekend, can’t wait to see how it performs!

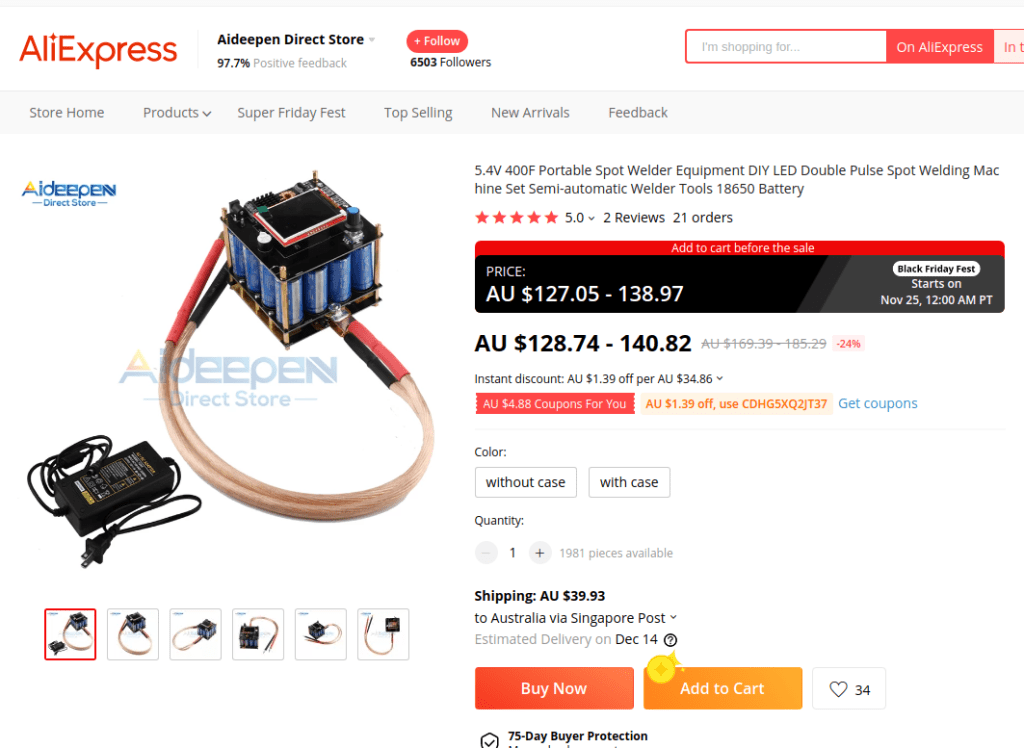

Make your own Battery pack – spot welding fun (part III)

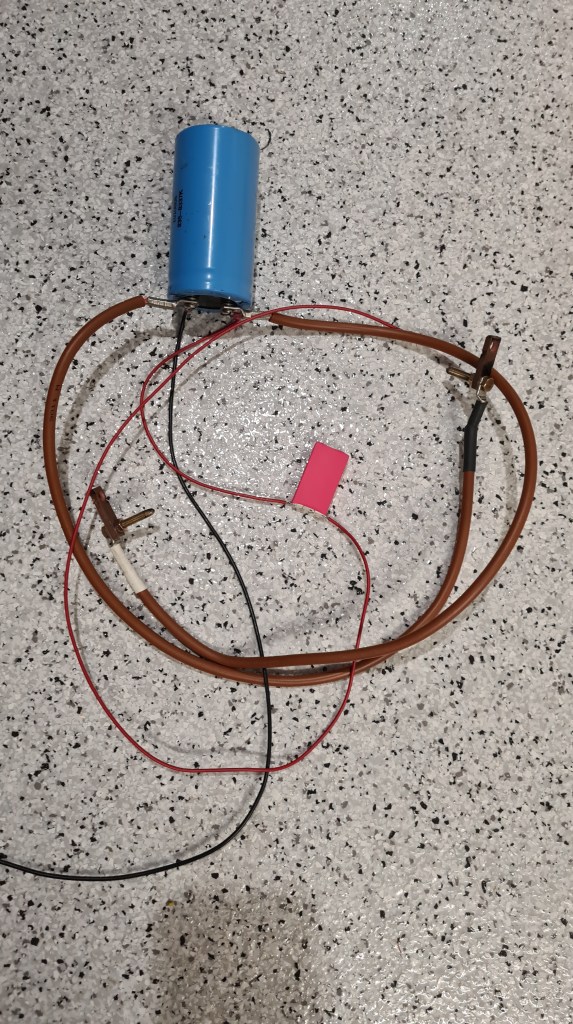

Couple weeks ago we’ve ended up last time with having a battery rack ready. Honestly not everything went that good as I was hoping for since, so we’ve hit about a week-ish delay on my plan. It looks like spot-welding is pretty difficult without a proper spot welder! Luckily Richard came back with an idea that he has some DIY one which should do the job. Here it is!

As you can see, it is just a simple-huge capacitor with a resistor to shield it from crashing a power source. Risa invited me to demonstrate how it is working and while it was giving super-cool sparks results didn’t make me confident that this is a way to go.

As you see on the last picture – nickel was quite damaged and it didn’t look reliable at all. Anyway we had couple beers and quite a fun trying and I took a video of Risa doing his best – Thank you Riso! 🙂

Needed to move on with the project, I started asking all around if someone would be able to borrow me a spot welder for a day or two – and Chris Drake came back! Luckily he had a trip around practically a next day when having some errands in Brisbane and brought me his own. And here it is – including a bag of Nickel. Thank you Chris!!!

While it looks quite wild and carries practically no label, it feels very very solid. I tried to locate that product on a web to get one on my own and while I can’t be 100% sure I think it is this one. Santa, if you are reading this – this is what I need! 😀

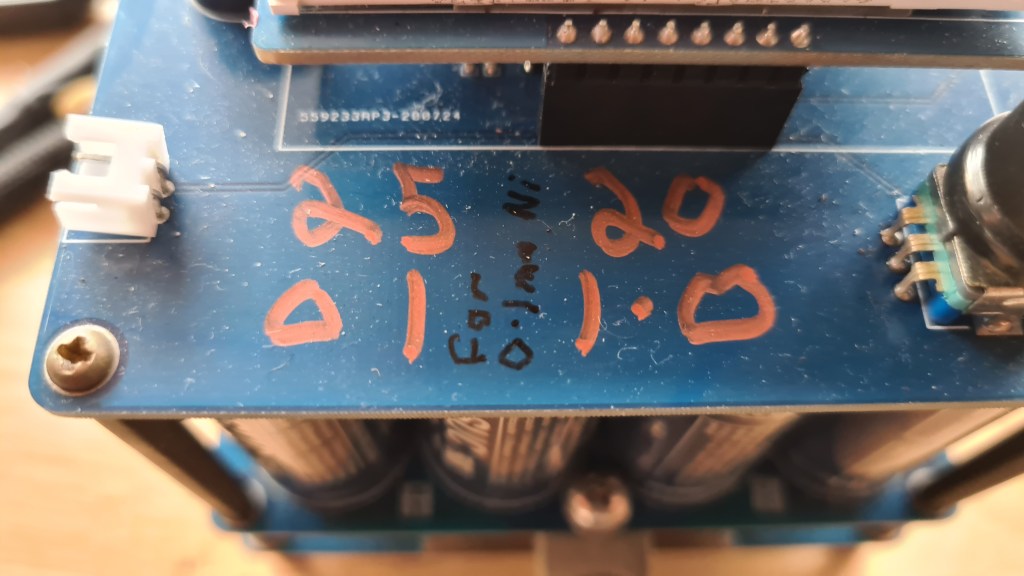

Anyway, it came with instructions – have a Nickel 0.2mm thick, then wait for it to charge first and use it with settings: pulse 1 is 25ms, pulse 2 is 20ms. This seem to be important enough that the owner made a note for himself straight on the case:

Now having access to the spot welder we should have everything for getting it all done! Well, making your own battery is easy, but there are few bits where it things ca go wrong. Perhaps that most important one (Thank you Riso) is to make sure that all cells are balanced on a same voltage, mainly those in parallel connection as they will attempt to re-balance at the moment when they are connected – potentially leading to an instant and spectacular charge/discharge. No need to say that consequences can be … well let’s just do everything to prevent it.

As you can see on the picture below, testing was fun. Majority of all batteries was around 3.6V +- 0.05, which I think is ok.

How ever there were few which needed an additional push. Luckily it wasn’t much a problem with topping them up with our PSU.

Unfortunately couple of those also needed to discharge and as our PSU doesn’t have that feature, Sebi put together a device to take care of that. Man it took so long to discharge one from 4.4V back to 3.6 – almost a day! Sebi needed to add one of our spare hi-LEDs to get us moving.

Meanwhile we’ve progressed on some serious welding. I you are having an impression that pictures are not a in correct timing sequence – all good, we’ve been working on two batteries in parallel and I thought it wouldn’t look too good interlacing story between those two processes.

Anyway, when I’ve got things in my hands, I asked Oli and Sebi to have a go as well.

Boys were sort of enjoying it, and while Oli pretended that it is not his most favourite, he actually also did very good job! I also did a couple of videos, so there is an evidence that even kids can do this work.

Well, let’s wrap it up here as there were many more things happening, but I don’t want posts to be too long. Anyway, well done guys and to be continued …

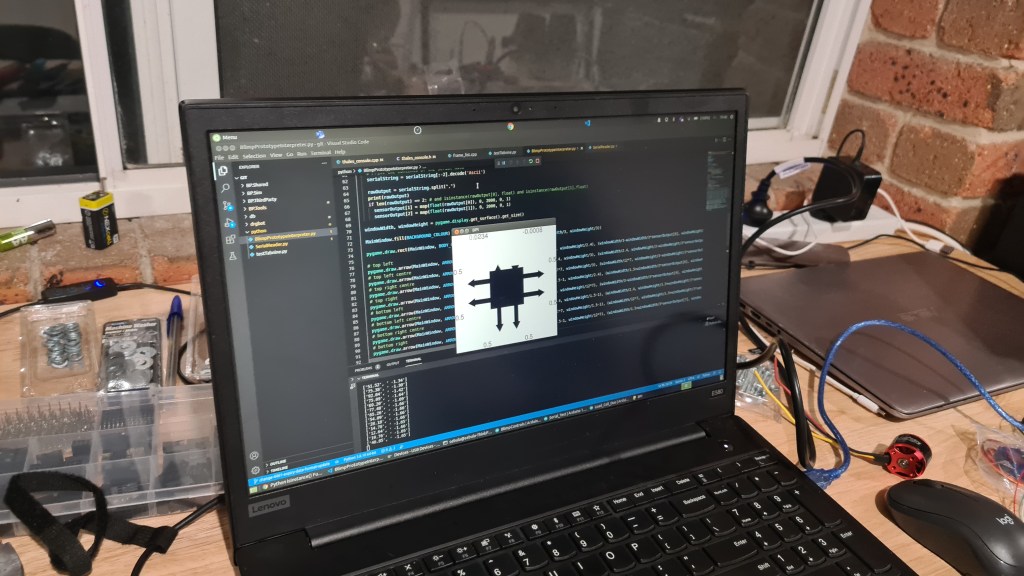

Two Load Cells

I asked Sebi to provide some option to visualise forces read by those cells and gave him a brief idea what I had on my mind thinking that it will entertain him for some time. Meanwhile I took on my the Monkey-business job of the cable crimping.

before

after

Not too shabby, huh? 🙂

Anyway, before I’ve been able to finish my crimping task – Sebi reported his part done!

What you see on the picture above is simplified graphical interpretation of our testing rig with forces pulling in a corner. I’ve asked Sebi to tell you what’s going on in his words.

I took a picture of whole setup.

And asked Sebi to give away his Python and Arduino code (Python first).

import pygame

import math

from pygame.time import Clock

import serial

def map(value = float, fromStart = float, fromEnd = float, toStart = float, toEnd = float):

return toStart + (toEnd - toStart) * ((value - fromStart) / (fromEnd - fromStart))

# specifications

ARROW_HEAD_SCALE = 1

ARROW_LINE_SCALE = 1

TEXT_SCALE = 1

OUTPUT_DECIMALS = 4

BACKGROUND_COLOUR = (255, 255, 255)

ARROW_HEAD_COLOUR = (0,0,0)

ARROW_LINE_COLOUR = (0,0,0)

BODY_COLOUR = (0,0,0)

TEXT_COLOUR = (0,0,0)

TEXT_FONT = "arial"

pygame.init()

# of specific dimension..e(X, Y).

MainWindow = pygame.display.set_mode((0, 0),

pygame.RESIZABLE, pygame.FULLSCREEN)

pygame.font.init() # you have to call this at the start,

# if you want to use this module.

# set the pygame window name

pygame.display.set_caption('BPI')

def arrow(screen, lcolour, tricolour, start, end, trirad, thickness=2):

rad = math.pi/180

pygame.draw.line(screen, lcolour, start, end, thickness)

rotation = (math.atan2(start[1] - end[1], end[0] - start[0])) + math.pi/2

pygame.draw.polygon(screen, tricolour, ((end[0] + trirad * math.sin(rotation),

end[1] + trirad * math.cos(rotation)),

(end[0] + trirad * math.sin(rotation - 120*rad),

end[1] + trirad * math.cos(rotation - 120*rad)),

(end[0] + trirad * math.sin(rotation + 120*rad),

end[1] + trirad * math.cos(rotation + 120*rad))))

setattr(pygame.draw, 'arrow', arrow)

sensorOutput = 8 * [0.5]

serialPort = serial.Serial(port = "/dev/ttyACM0", baudrate=9600,

bytesize=8, timeout=2, stopbits=serial.STOPBITS_ONE)

serialString = "" # Used to hold data coming over UART

# infinite loop

while True:

if(serialPort.in_waiting > 0):

# Read data out of the buffer until a carraige return / new line is found

serialString = serialPort.readline()

# Print the contents of the serial data

serialString = serialString[:-2].decode('Ascii')

rawOutput = serialString.split(",")

print(rawOutput)

if len(rawOutput) == 2: # and isinstance(rawOutput[0], float) and isinstance(rawOutput[1],float)

sensorOutput[1] = map(float(rawOutput[0]), 0, 2000, 0, 1)

sensorOutput[2] = map(float(rawOutput[1]), 0, 2000, 0, 1)

windowWidth, windowHeight = pygame.display.get_surface().get_size()

MainWindow.fill(BACKGROUND_COLOUR)

pygame.draw.rect(MainWindow, BODY_COLOUR, (windowWidth/3, windowHeight/3, windowWidth/3, windowHeight/3))

# top left

pygame.draw.arrow(MainWindow, ARROW_LINE_COLOUR, ARROW_HEAD_COLOUR, (windowWidth/3, windowHeight/2.4), (windowWidth/3-windowWidth/3*sensorOutput[0], windowHeight/2.4), round(windowWidth/24)*ARROW_HEAD_SCALE, round(windowWidth/24)*ARROW_LINE_SCALE)

# top left centre

pygame.draw.arrow(MainWindow, ARROW_LINE_COLOUR, ARROW_HEAD_COLOUR, (windowWidth/2.4, windowHeight/3), (windowWidth/2.4, windowHeight/3-windowHeight/3*sensorOutput[1]), round(windowWidth/24)*ARROW_HEAD_SCALE, round(windowWidth/24)*ARROW_LINE_SCALE)

# top right centre

pygame.draw.arrow(MainWindow, ARROW_LINE_COLOUR, ARROW_HEAD_COLOUR, (windowWidth/12*7, windowHeight/3), (windowWidth/12*7, windowHeight/3-windowHeight/3*sensorOutput[2]), round(windowWidth/24)*ARROW_HEAD_SCALE, round(windowWidth/24)*ARROW_LINE_SCALE)

# top right

pygame.draw.arrow(MainWindow, ARROW_LINE_COLOUR, ARROW_HEAD_COLOUR, (windowWidth/1.5-1, windowHeight/2.4), (windowWidth/1.5+windowWidth/3*sensorOutput[6], windowHeight/2.4), round(windowWidth/24)*ARROW_HEAD_SCALE, round(windowWidth/24)*ARROW_LINE_SCALE)

# bottom left

pygame.draw.arrow(MainWindow, ARROW_LINE_COLOUR, ARROW_HEAD_COLOUR, (windowWidth/3, windowHeight/12*7), (windowWidth/3-windowWidth/3*sensorOutput[4], windowHeight/12*7), round(windowWidth/24)*ARROW_HEAD_SCALE, round(windowWidth/24)*ARROW_LINE_SCALE)

# bottom left centre

pygame.draw.arrow(MainWindow, ARROW_LINE_COLOUR, ARROW_HEAD_COLOUR, (windowWidth/2.4, windowHeight/1.5-1), (windowWidth/2.4, windowHeight/1.5+windowHeight/3*sensorOutput[5]), round(windowWidth/24)*ARROW_HEAD_SCALE, round(windowWidth/24)*ARROW_LINE_SCALE)

# bottom right centre

pygame.draw.arrow(MainWindow, ARROW_LINE_COLOUR, ARROW_HEAD_COLOUR, (windowWidth/12*7, windowHeight/1.5-1), (windowWidth/12*7, windowHeight/1.5+windowHeight/3*sensorOutput[3]), round(windowWidth/24)*ARROW_HEAD_SCALE, round(windowWidth/24)*ARROW_LINE_SCALE)

# bottom right

pygame.draw.arrow(MainWindow, ARROW_LINE_COLOUR, ARROW_HEAD_COLOUR, (windowWidth/1.5-1, windowHeight/12*7), (windowWidth/1.5+windowWidth/3*sensorOutput[7], windowHeight/12*7), round(windowWidth/24)*ARROW_HEAD_SCALE, round(windowWidth/24)*ARROW_LINE_SCALE)

textFont = pygame.font.SysFont(TEXT_FONT, round((windowWidth/26)+(windowHeight/26)/2*TEXT_SCALE))

topLeft = textFont.render(str(round(sensorOutput[0],OUTPUT_DECIMALS)), True, TEXT_COLOUR)

topLeftCentre = textFont.render(str(round(sensorOutput[1],OUTPUT_DECIMALS)), True, TEXT_COLOUR)

topRightCentre = textFont.render(str(round(sensorOutput[2],OUTPUT_DECIMALS)), True, TEXT_COLOUR)

topRight = textFont.render(str(round(sensorOutput[3],OUTPUT_DECIMALS)), True, TEXT_COLOUR)

bottomLeft = textFont.render(str(round(sensorOutput[4],OUTPUT_DECIMALS)), True, TEXT_COLOUR)

bottomLeftCentre = textFont.render(str(round(sensorOutput[5],OUTPUT_DECIMALS)), True, TEXT_COLOUR)

bottomRightCentre = textFont.render(str(round(sensorOutput[6],OUTPUT_DECIMALS)), True, TEXT_COLOUR)

bottomRight = textFont.render(str(round(sensorOutput[7],OUTPUT_DECIMALS)), True, TEXT_COLOUR)

MainWindow.blit(topLeft, dest=(0, windowHeight/3-topLeft.get_height()))

MainWindow.blit(topLeftCentre, dest = (windowWidth/3-topLeftCentre.get_width(), 0))

MainWindow.blit(topRightCentre, dest = (windowWidth/1.5, 0))

MainWindow.blit(topRight, dest=(windowWidth-topRight.get_width(), windowHeight/3-topRight.get_height()))

MainWindow.blit(bottomLeft, dest=(0, windowHeight/1.5))

MainWindow.blit(bottomLeftCentre, dest=(windowWidth/3-bottomLeftCentre.get_width(), windowHeight-bottomLeftCentre.get_height()))

MainWindow.blit(bottomRightCentre, dest=(windowWidth/1.5, windowHeight-bottomRightCentre.get_height()))

MainWindow.blit(bottomRight, dest=(windowWidth-bottomRight.get_width(), windowHeight/1.5))

pygame.display.update()

Clock().tick_busy_loop(20)

Now Arduino

#include "HX711.h"

#define calibration_factor -21600 //This value is obtained using the SparkFun_HX711_Calibration sketch

#define LOADCELL_DOUT_PIN 3

#define LOADCELL_SCK_PIN 2

HX711 scale1;

HX711 scale2;

void setup() {

Serial.begin(9600);

Serial.println("HX711 scale demo");

scale1.begin(3, 2);

scale1.set_scale(calibration_factor); //This value is obtained by using the SparkFun_HX711_Calibration sketch

scale1.tare(); //Assuming there is no weight on the scale at start up, reset the scale to 0

scale2.begin(5, 4);

scale2.set_scale(calibration_factor); //This value is obtained by using the SparkFun_HX711_Calibration sketch

scale2.tare(); //Assuming there is no weight on the scale at start up, reset the scale to 0

Serial.println("Readings:");

}

void loop() {

String full = String(scale1.get_units()*10)+", "+String(scale2.get_units()*10);

Serial.println(full);

delay(100);

}

Pretty nice, isn’t it? As always, let us know what you think about it 😉

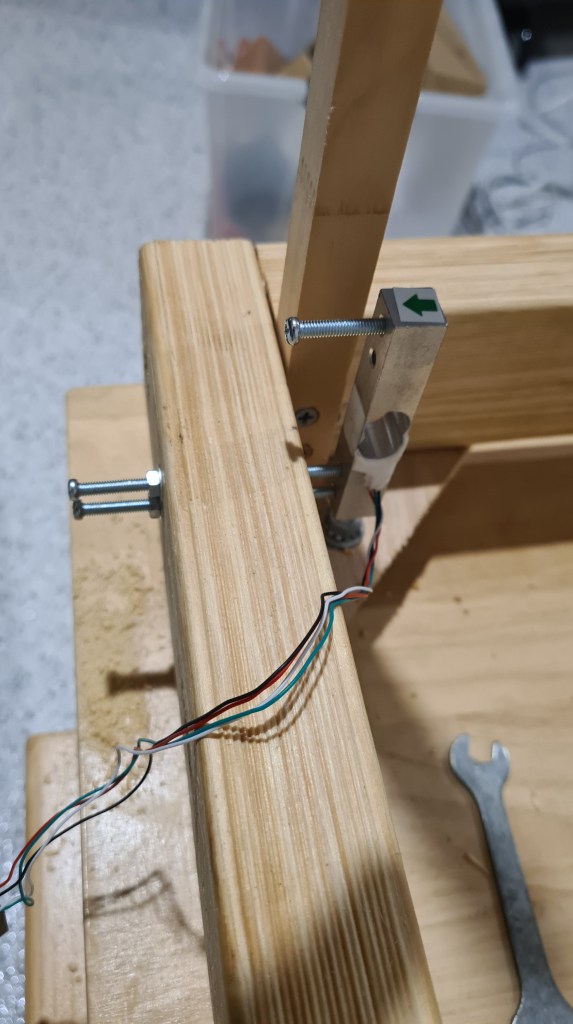

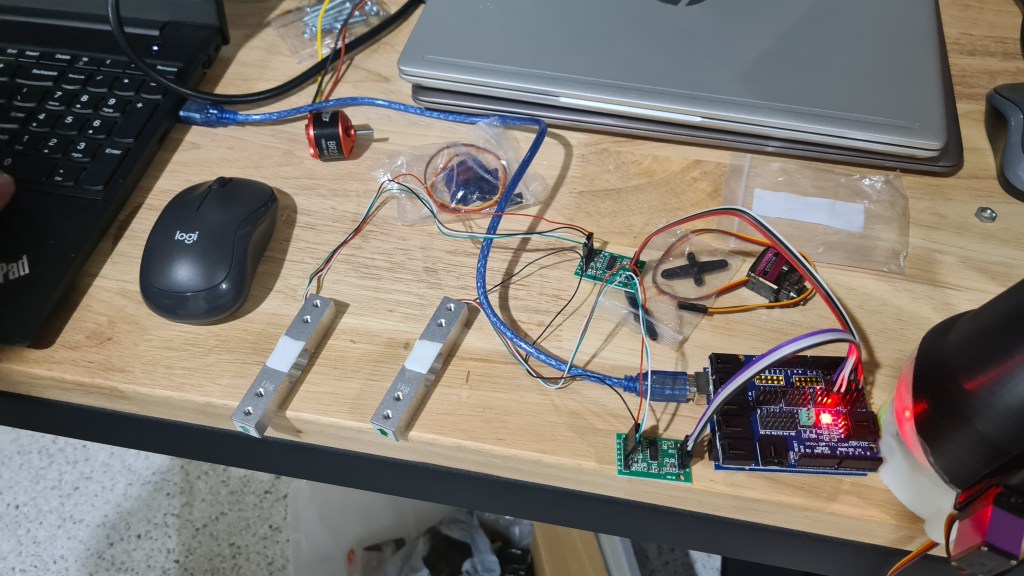

Load cells

Couple months back I ordered from AliExpress set of Load Cell sensors for our testing rig project .

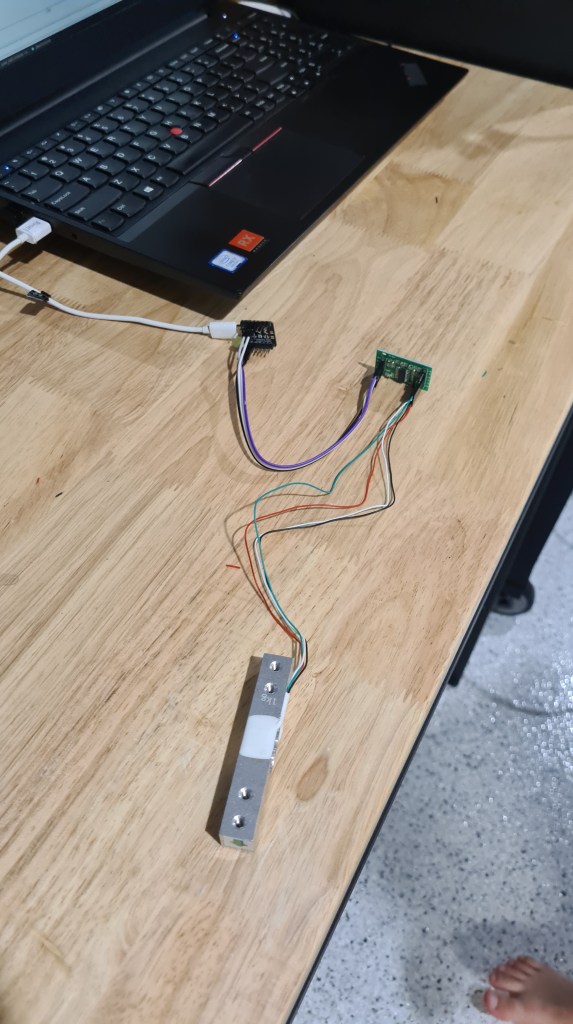

Those arrived in a good shape and while being pretty interested into how those work, it took us a bit to get to them.

Sebi prepared a setup to give it a go. That aluminium thing is our load cell, it is connected to an amplifier, which is connected to some ArduinoNano and all that chain ends in Sebi’s laptop through USB. Each load cell comes with an arrow showing direction in which forces should be applied.

I’ve asked Sebi to describe it in his words.

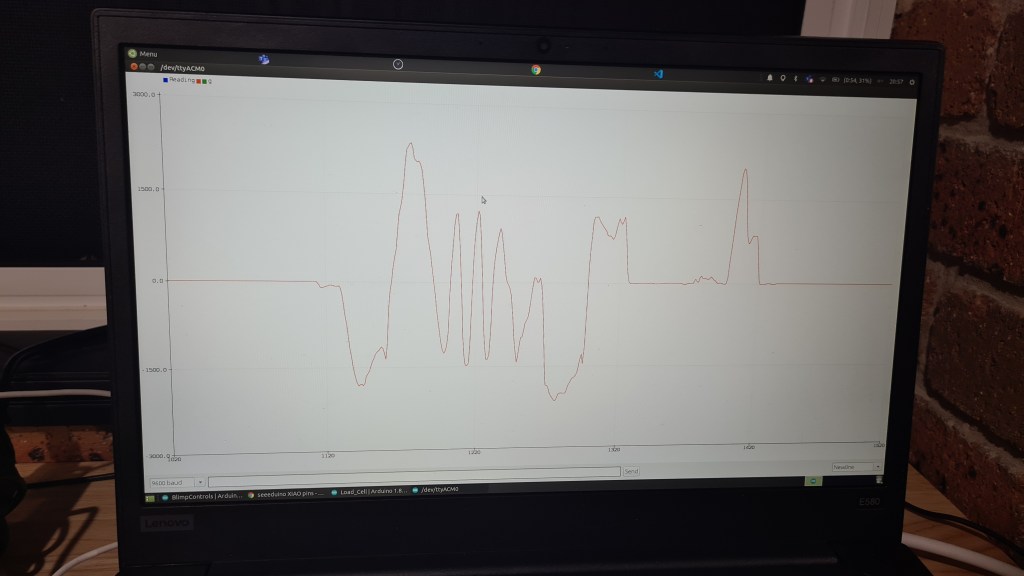

Seeing that video, I noticed that that final plot is probably not visible properly, so I took a close picture. Interestingly you can see positive and also negative values, that may come pretty handy. Also while that load cell says that it is up to 1kg (9.80665N) we’ve been seeing even higher values (1.2kg).

If you would be interested in reproducing the same, Sebi shared with me his source code.

#include "HX711.h"

#define calibration_factor -21600 //This value is obtained using the SparkFun_HX711_Calibration sketch

#define LOADCELL_DOUT_PIN 3

#define LOADCELL_SCK_PIN 2

HX711 scale;

void setup() {

Serial.begin(9600);

Serial.println("HX711 scale demo");

scale.begin(LOADCELL_DOUT_PIN, LOADCELL_SCK_PIN);

scale.set_scale(calibration_factor); //This value is obtained by using the SparkFun_HX711_Calibration sketch

scale.tare(); //Assuming there is no weight on the scale at start up, reset the scale to 0

Serial.println("Readings:");

}

void loop() {

Serial.print("Reading: ");

Serial.print(scale.get_units()*10, 1); //scale.get_units() returns a float

Serial.print(" g"); //You can change this to kg but you'll need to refactor the calibration_factor

Serial.println();

}

Now you probably wonder what it is for .. well here are few pictures to tune you up, but it is still work-in-progress so I’ll leave the rest for another article. 😉

So I think this was a pretty good progress for one day! So don’t forget to leave some message for Sebi – those motivate him a lot. 😉

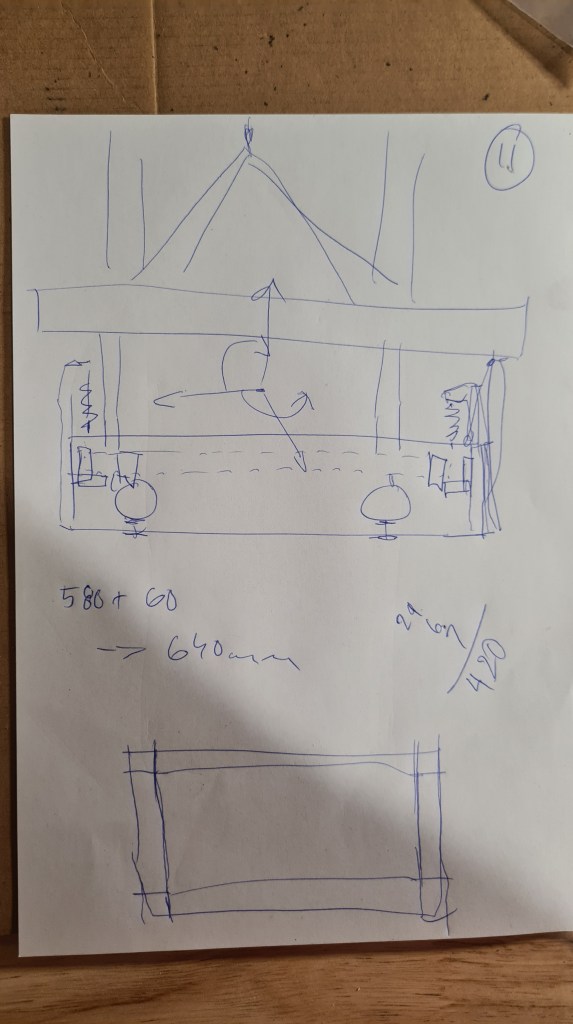

Test rig – part I

One of the problems I can’t stop thinking about is how we are going to steer that airship. It is easy to do steering like we are doing it today – when we have just two motors and two vectored thrusters, but how’s that all going to look like with that plus 4 more gimbals? To see it all working I came with an idea of a test rig which would allow us to develop a control mechanics and test those easily.

It took a while to come from an idea to practicalities, but I’ve been finally able to explain all what I am looking for to Serge and we came with a plan:

I understand that it looks bit wild now, but what you are looking at is our future testing rig. Just imagine a frame wider than our cart which surrounds it with multiple weight sensors on all sides. It also comes with a facility to balance whole cart in the air so all values the reads from sensors are not biased with any friction coming from wheels. Finally whole system is completely stationary and shouldn’t move at all so there is no need to reset it. Also whole system to be fed by that 2kW PSU (24V, up to 81A) which arrived couple weeks ago to mitigate any power fluctuations from batteries.

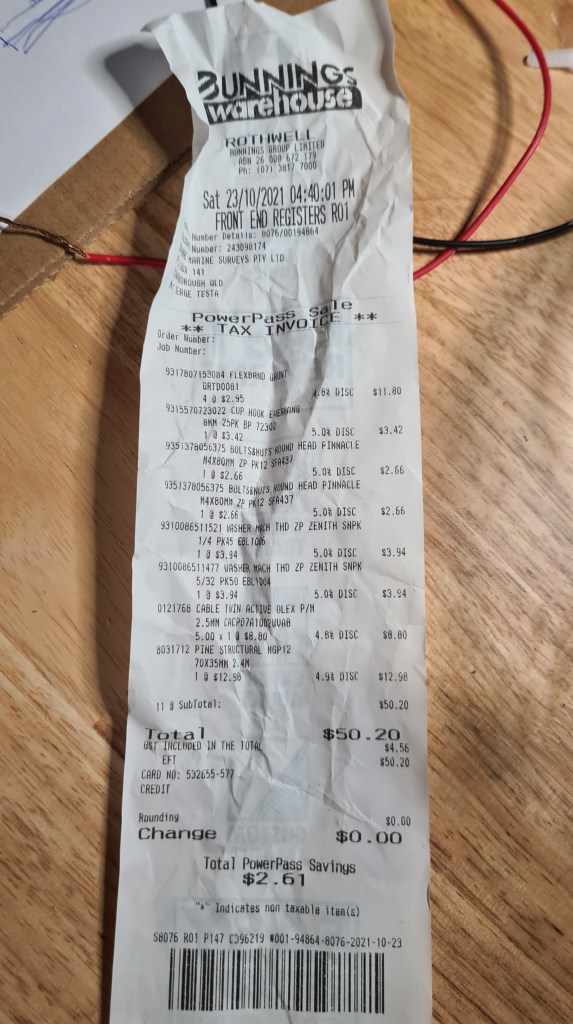

After agreeing with the plan with Serge, we went shopping – to local Bunnings store. It was cheaper than what I initially thought of.

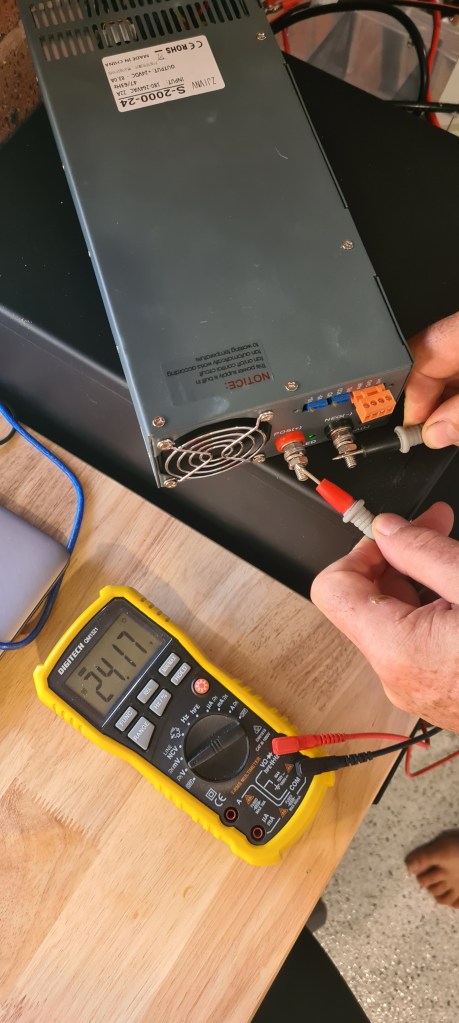

Surprisingly we didn’t start with the frame, but with the PSU. Serge quickly mounted power plug and I did bit of soldering with XT-90 to fit our power bridge. Multi-tool confirmed that have it all right – 24.17V. Same voltage came at the end of that 5m 2.5mm copper twin cable, what was quite relief as I was bit worried about some decline there.

Let’s see how is all that going to perform when feeding 6 motors on a full power. A screenshot from calculator below shows that it shouldn’t necessarily burn out.

Well, than it was lots of measuring, cutting and screwing – unfortunately we were so efficient that I forgot to take pictures. I took few afterwards. The first one gives a good overview on what we achieved. There firm frame with posts and rubber bands.