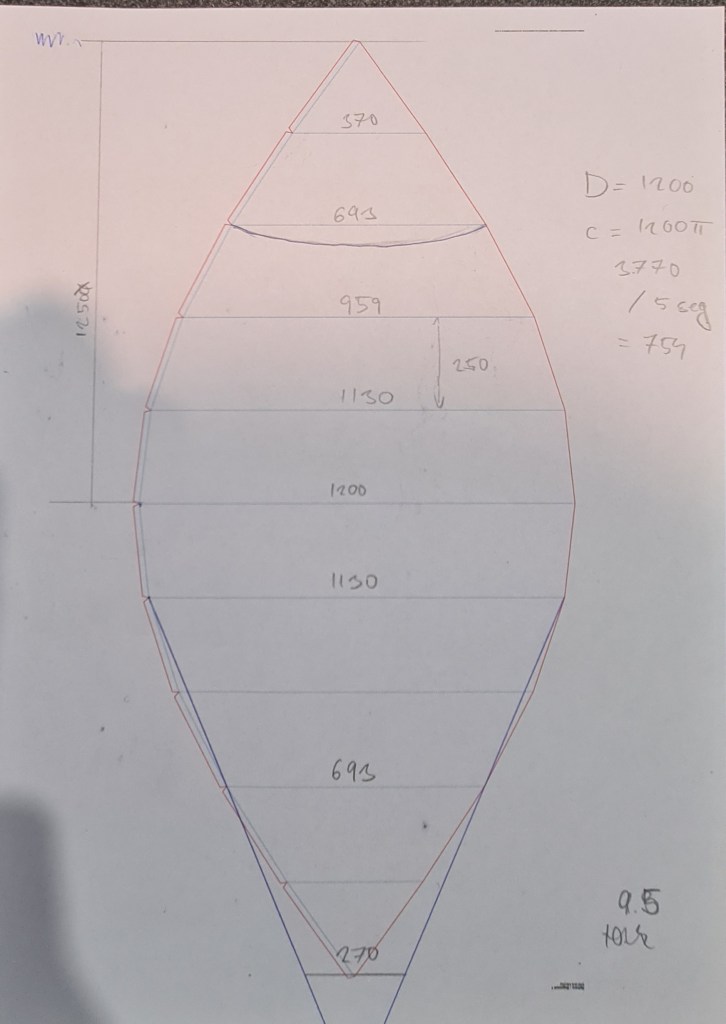

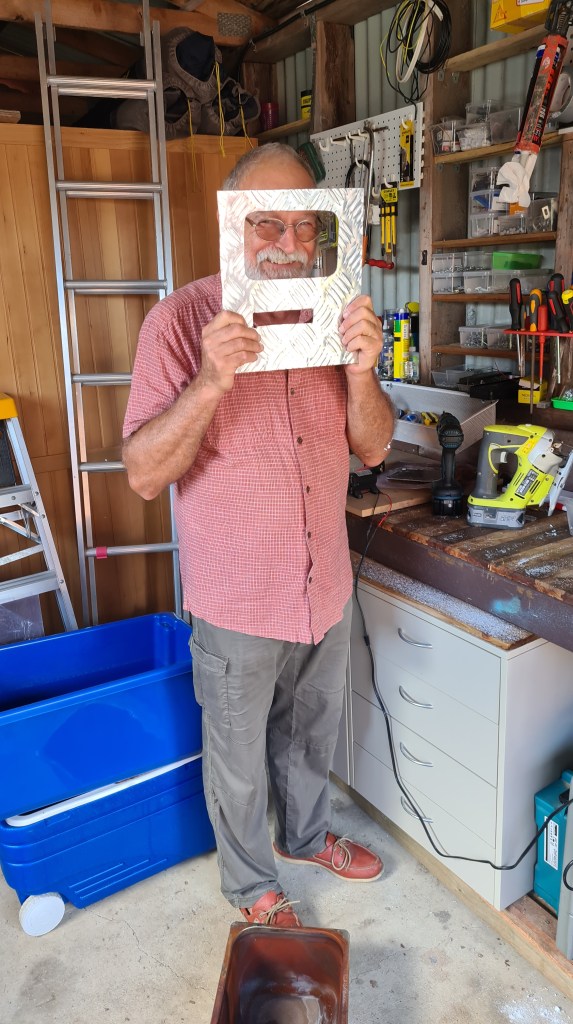

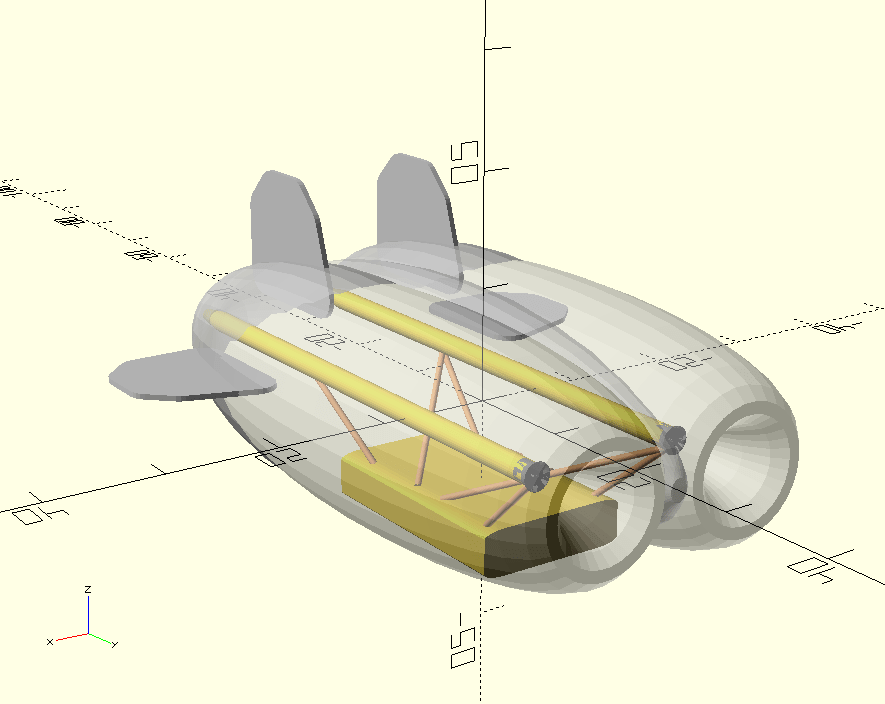

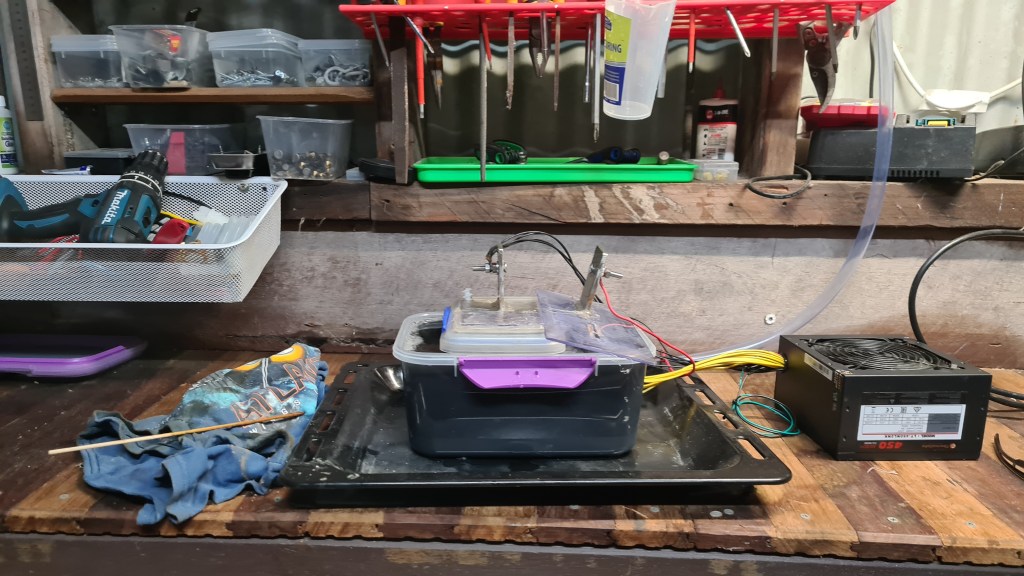

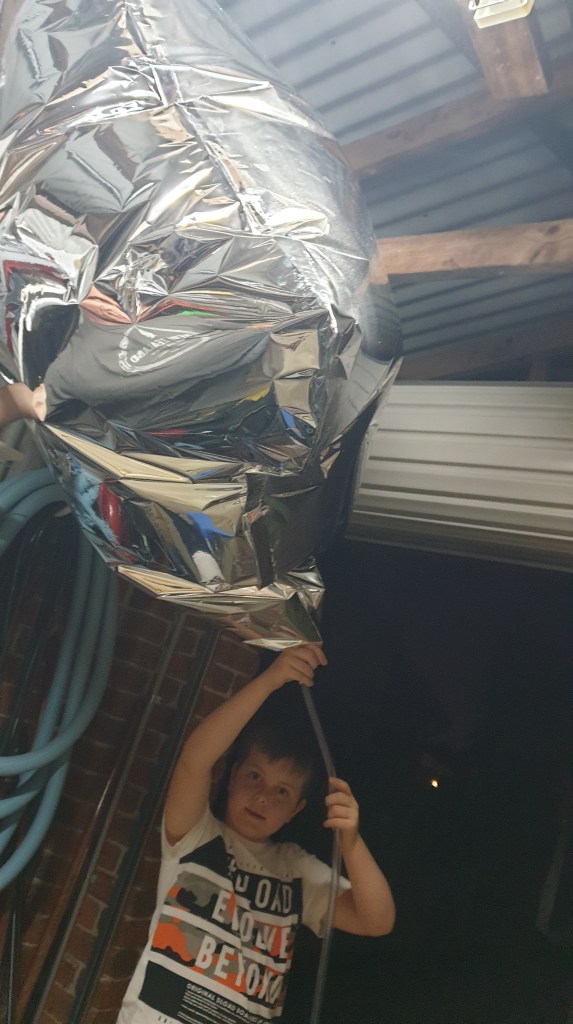

The idea here is to send our next balloon with a hanging beacon. Beacon to repeatedly keep sending out a Morse-code encoded message (currently thinking about some Chuck Norris jokes). I’ve covered my rough plan on a picture below.

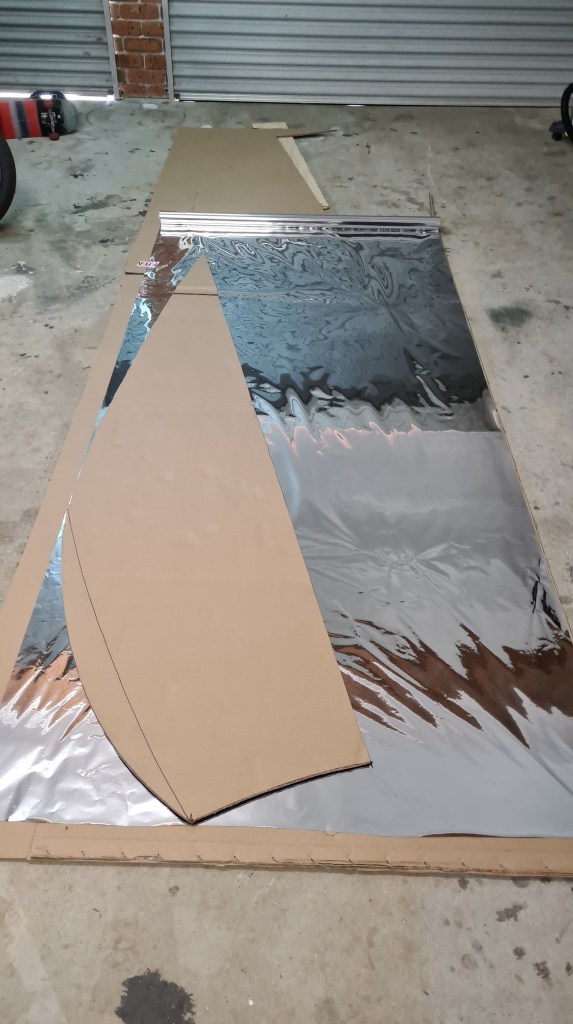

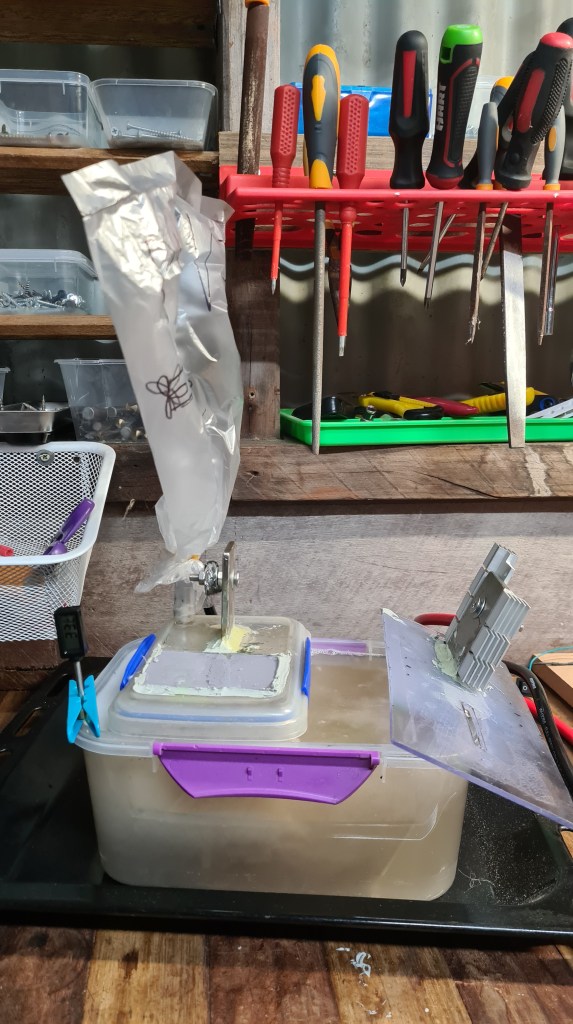

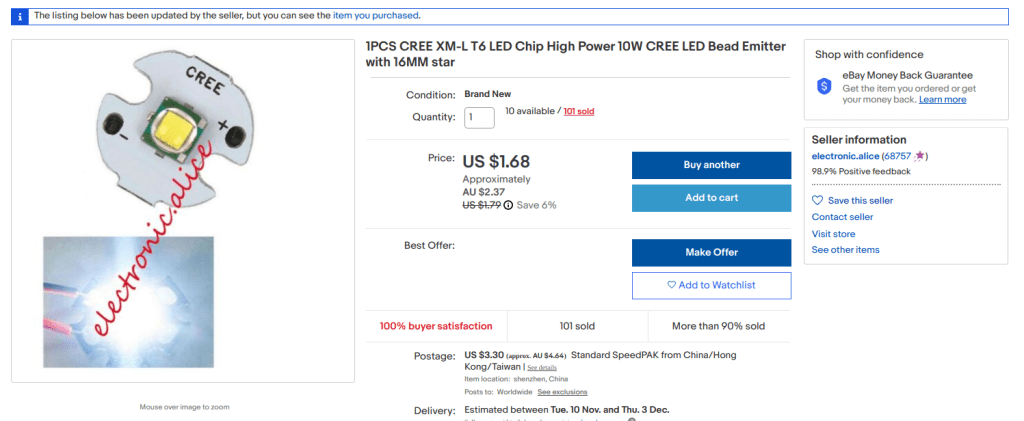

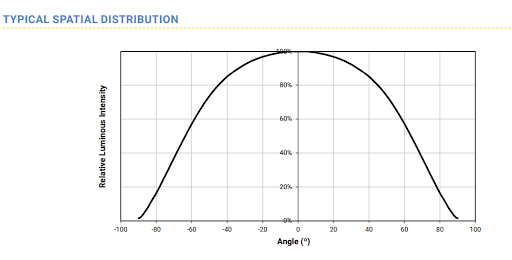

LEDs to be organised in a triangular or pyramid shape, covering surrounding area and facing 45 degrees down. I’ve discussed this with Risa and he came with a plan. It first came with an order of some super-powerful LEDs to do the job properly – Model Type: Cree XML-T6.

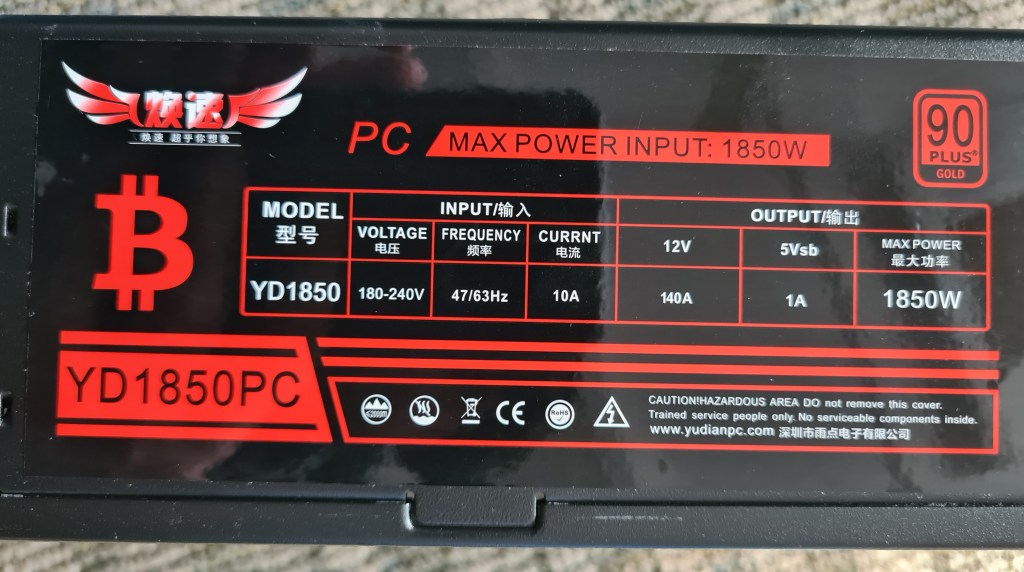

Technical Parameters

DC Forward Voltage (VF): 2.9-4Vdc

DC Forward Current (IF): 3.0A

Low thermal resistance: 2.5°C/W

Maximum junction temperature: 150C

Viewing angle: 125°

ANSI-compatible chromaticity bins

Unlimited floor life at <30C/85% RH

Reflow solderable-JEDES J-STD-020C

Electrically neutral thermal path

Emitted Color :White

Color Temperature: 6500-7000K

Power: 10W

Diameter : 16mm

Ordered 10 of them and those came a week later.

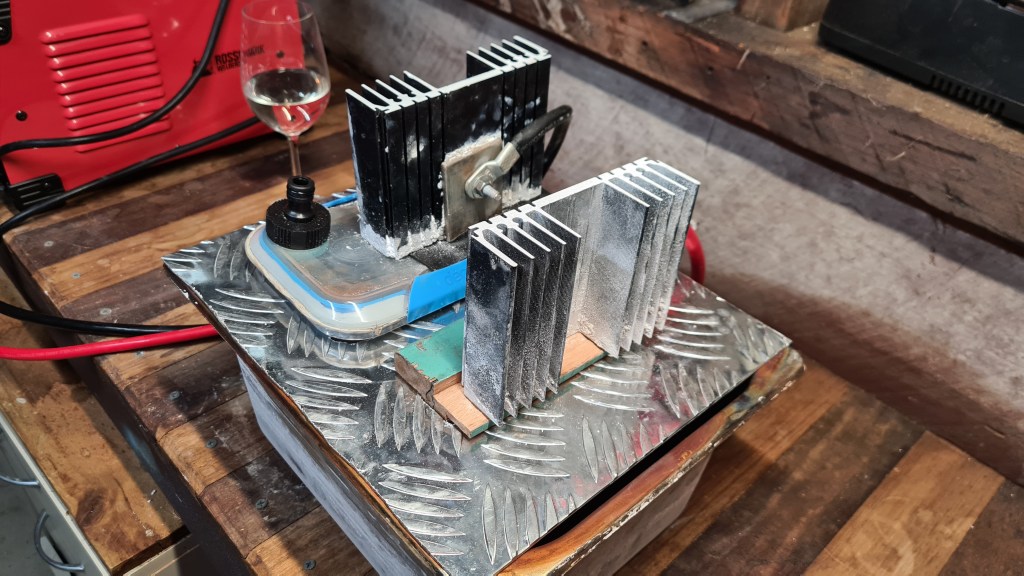

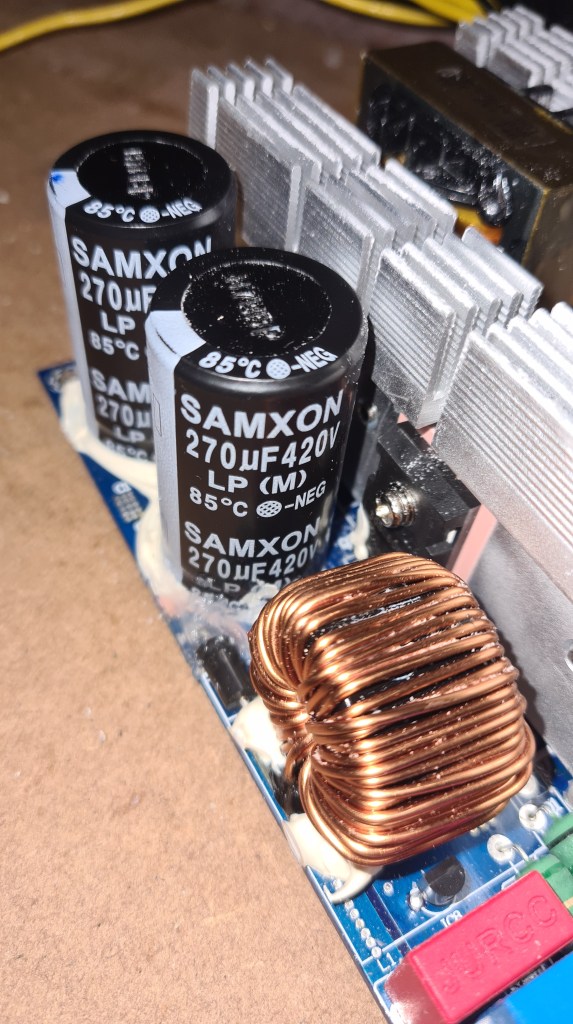

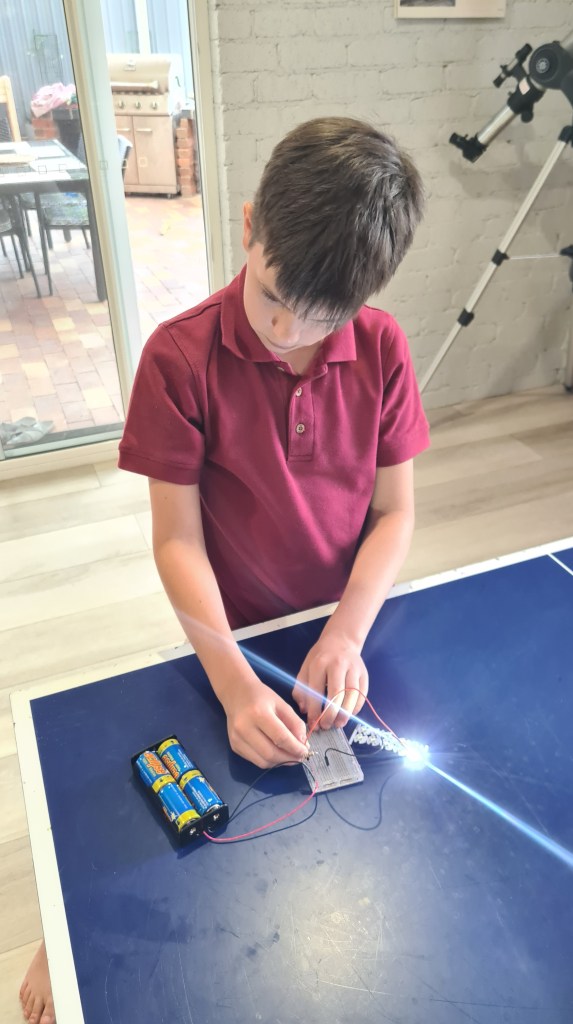

Being eager to test those, Risa provided wiring instructions + list of components needed to bring it to live.

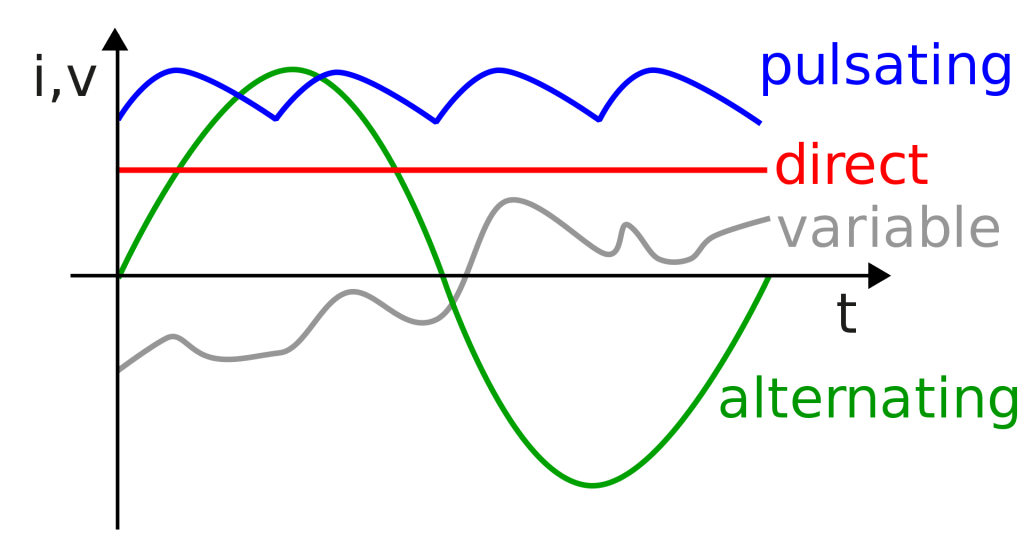

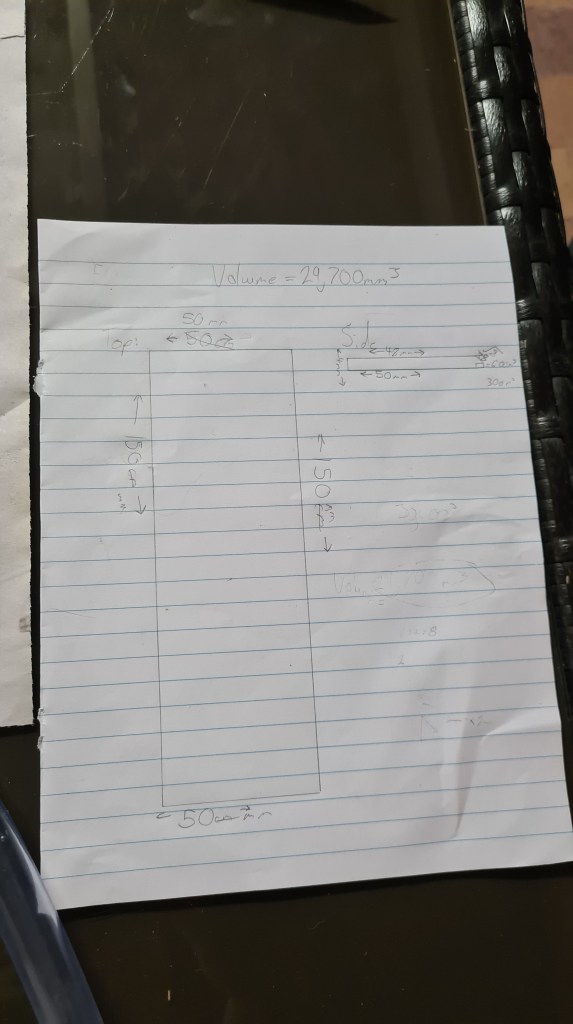

So in the above diagram Ra should will be new 15 ohm resistor and Rb our new CREE LED. Vin is a 6 volt battery. This will allow 200 milliamps to flow through the LED and the heat dissipated will be roughly 600 miliWatts.

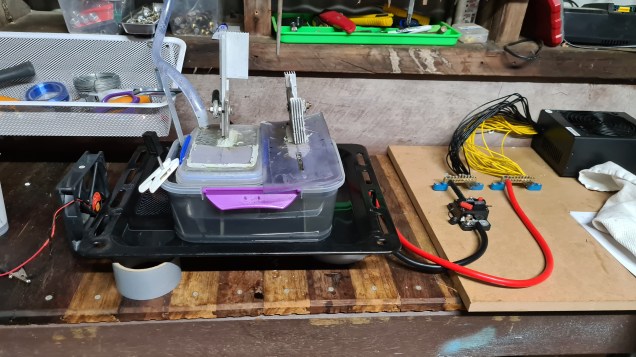

Another quick visit to JayCar and we had all needed.

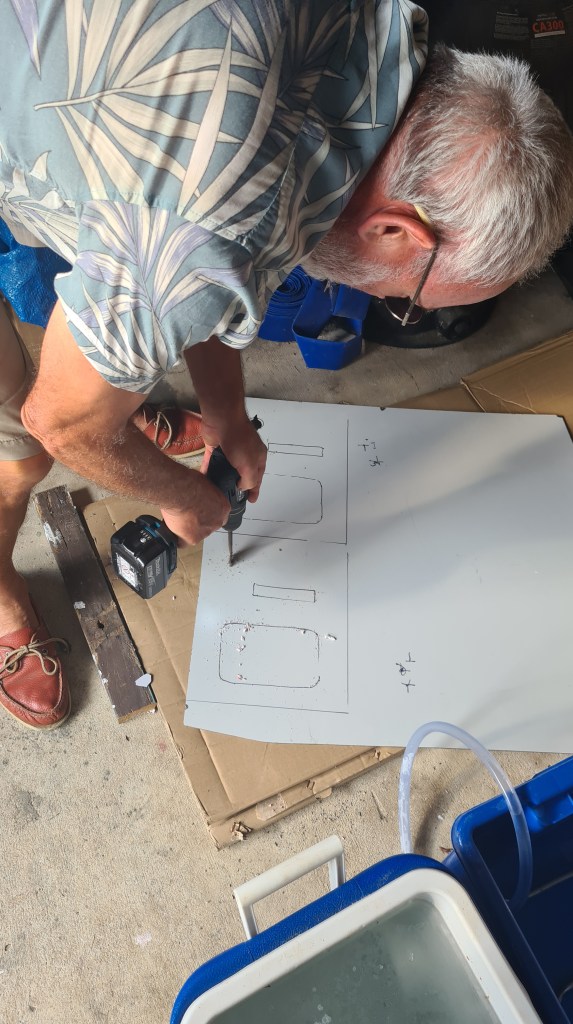

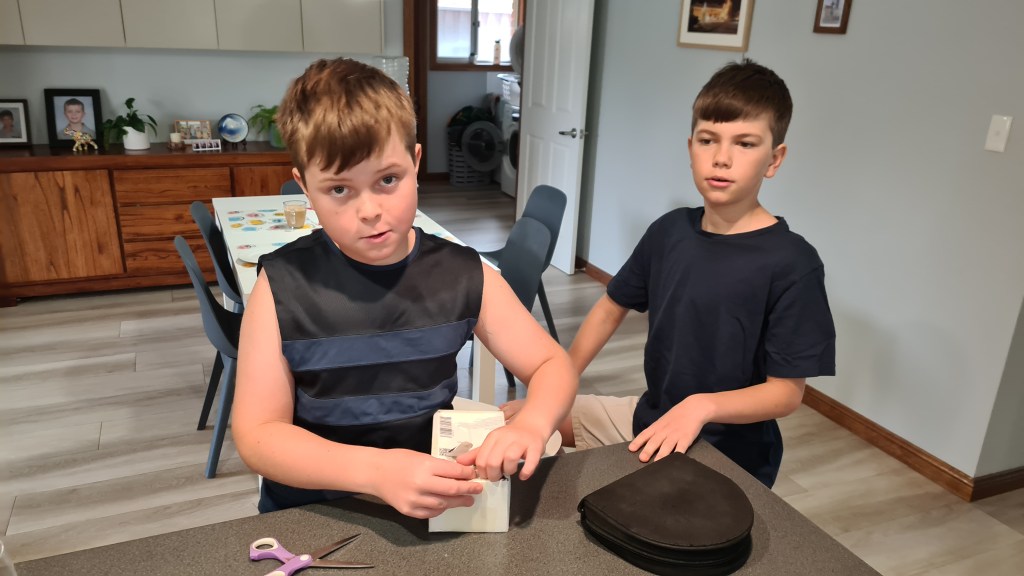

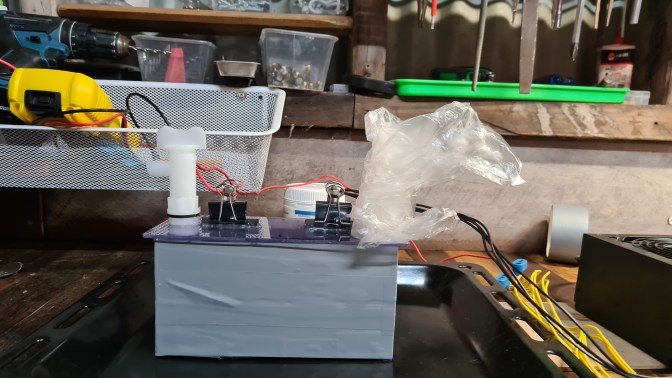

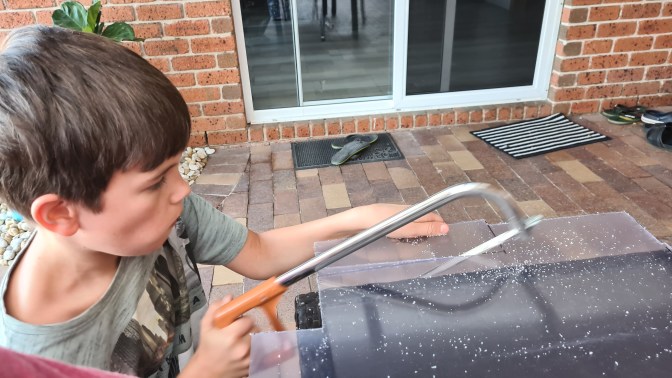

Sebi wired all components together though his bread-board and everything worked out practically out of the box.

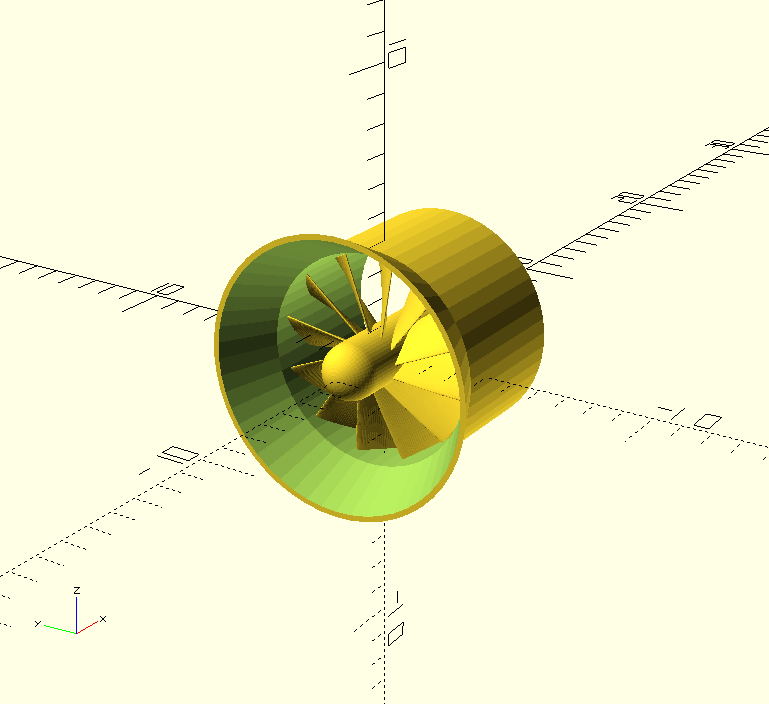

Risa then asked Sebi to write an application which would send a signal to any pin he choose for 100ms on then off for 3sec. Sebi commented this as a “piece of cake” and had it done in next 10 minutes (including demonstration).

const int output = 3;

void setup() {

pinMode(output, OUTPUT);

}

void loop() {

digitalWrite(output, LOW);

delay(100);

digitalWrite(output, HIGH);

delay(3000);

}I’ve captured that on a short video below.

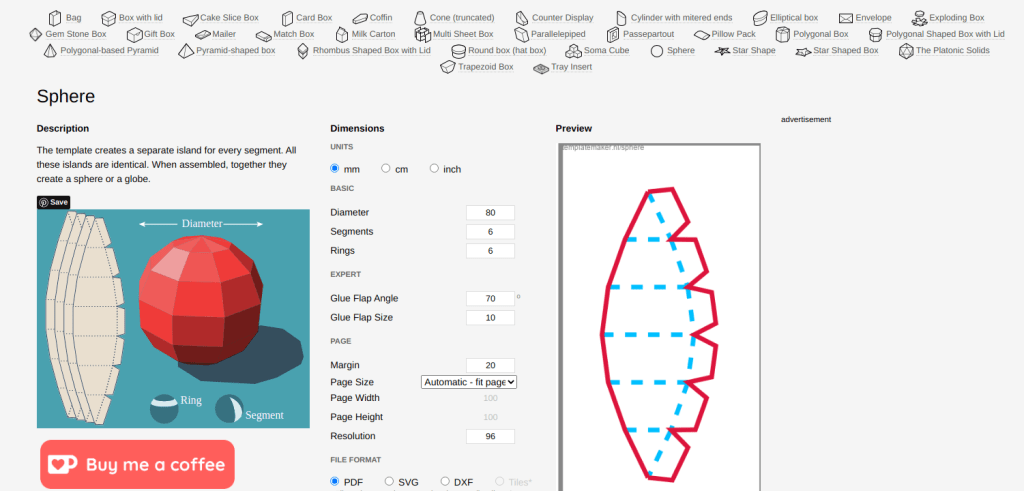

Next stage will be to design a proper holder for a set of LEDs, calculate power consumption and also Sebi to write our Chunojomor – (Chuck-Norris-joke-Morse-translator).