Guest information

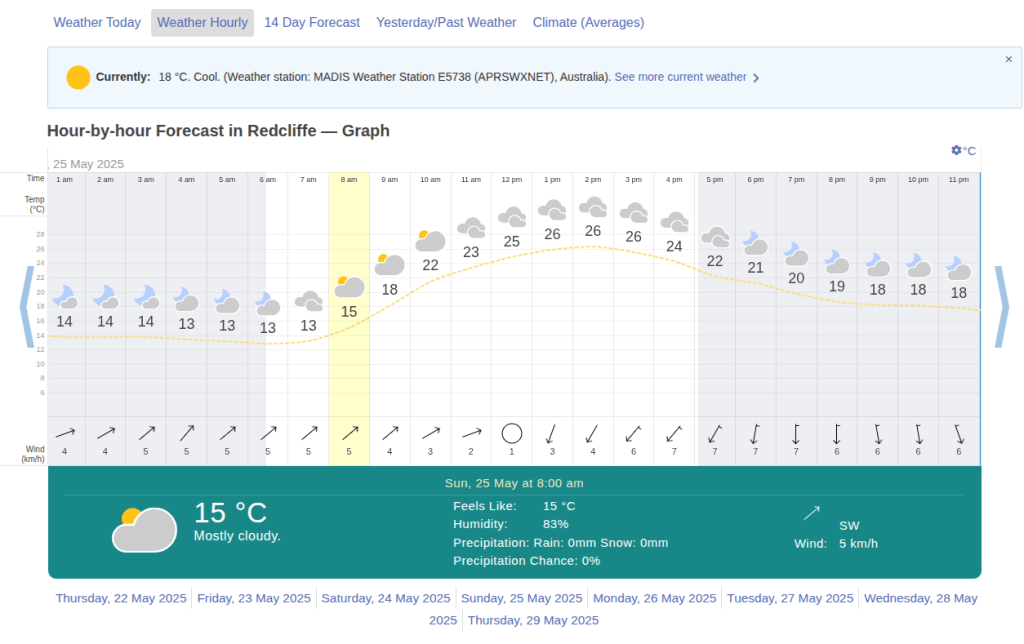

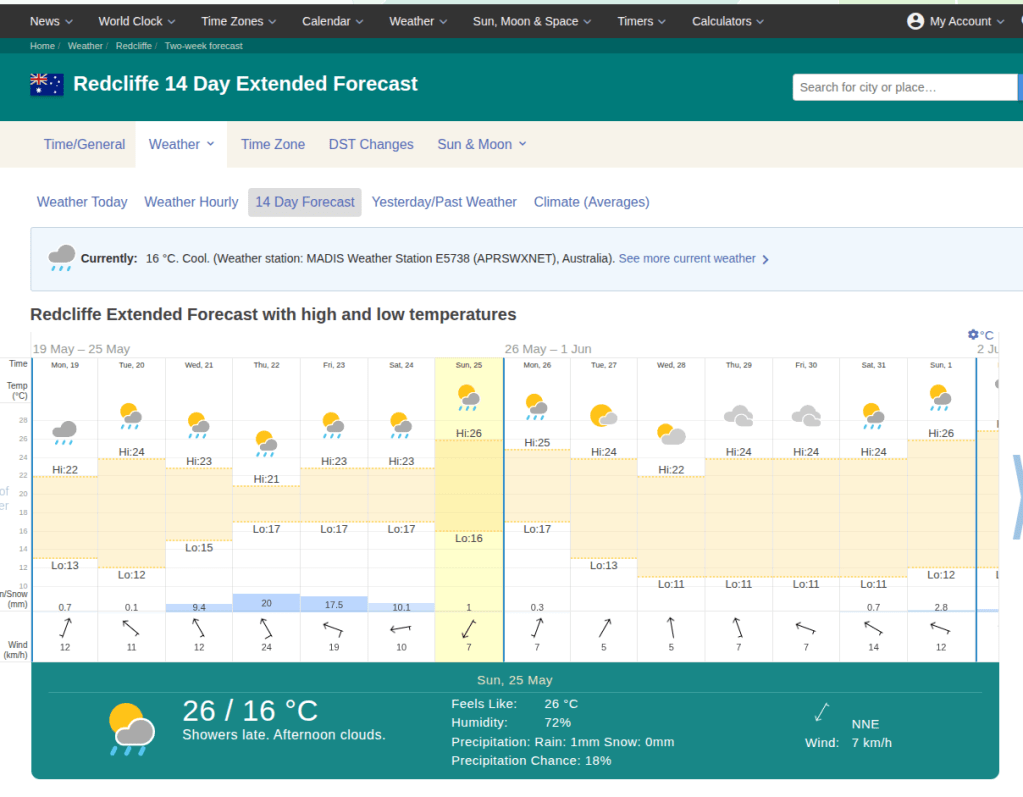

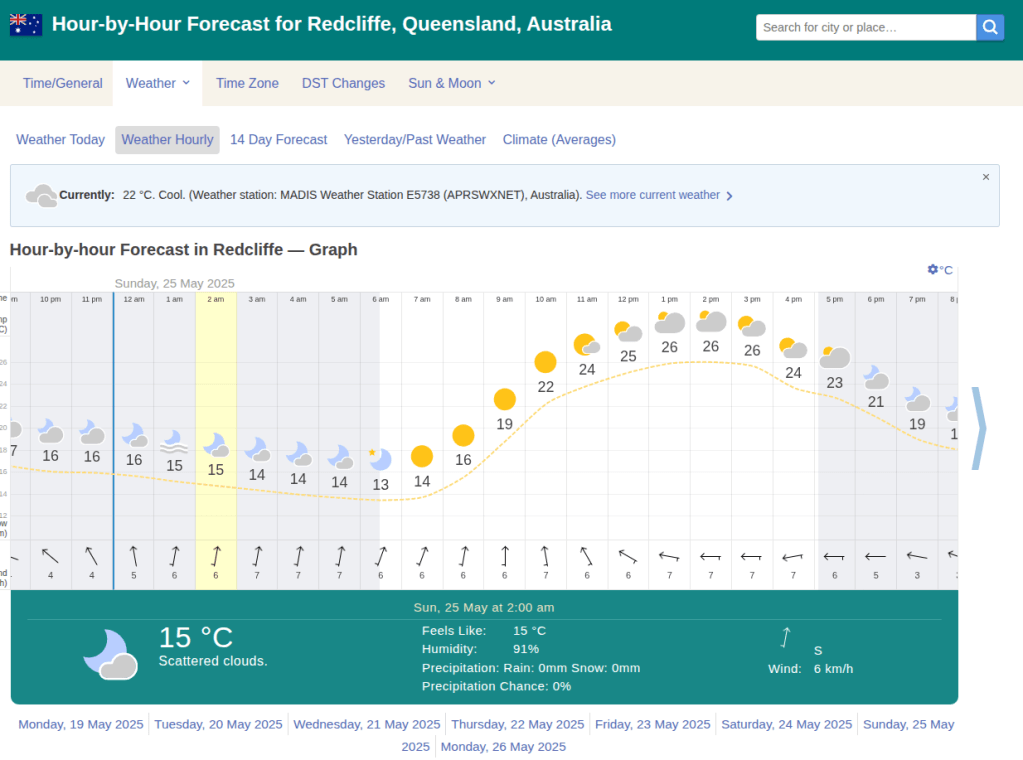

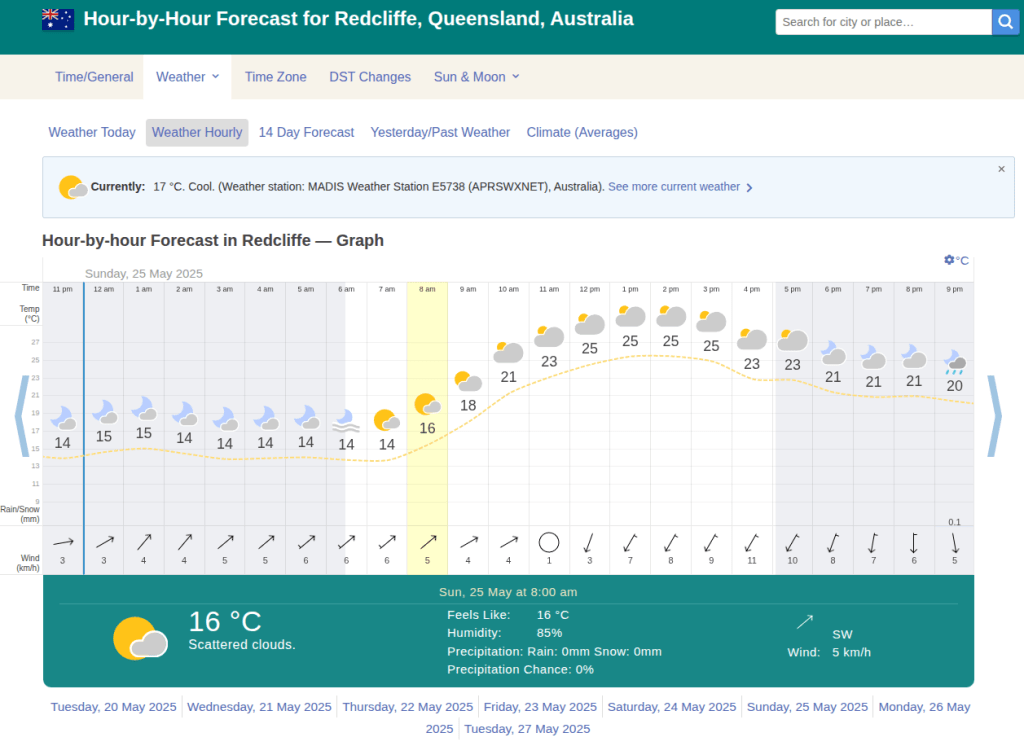

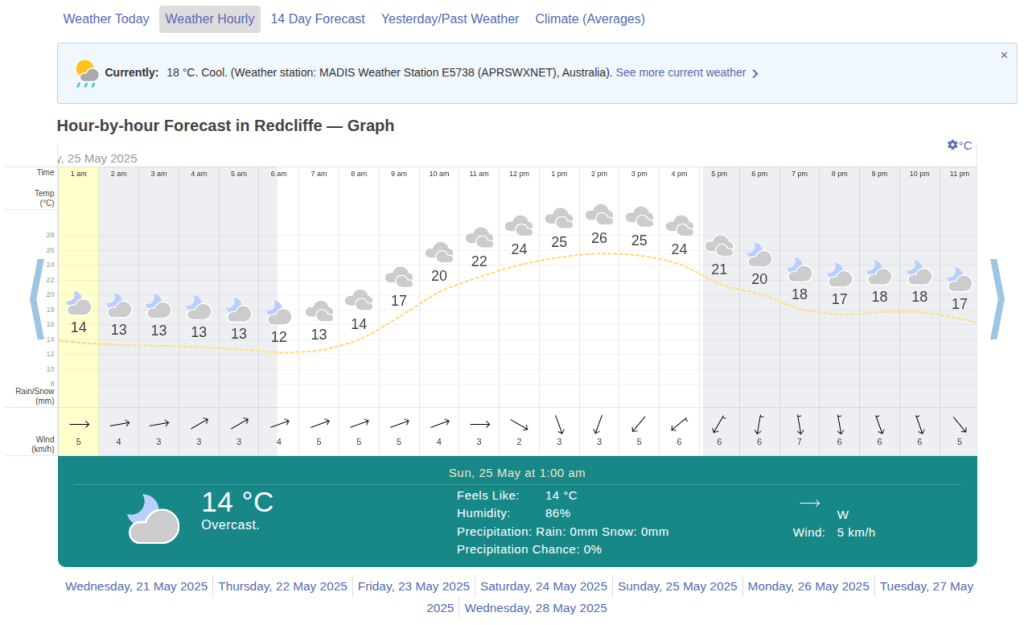

When: 25th May, or 1st June (weather conditions depending)

Launch time (estimated): 8:00-9:00 am

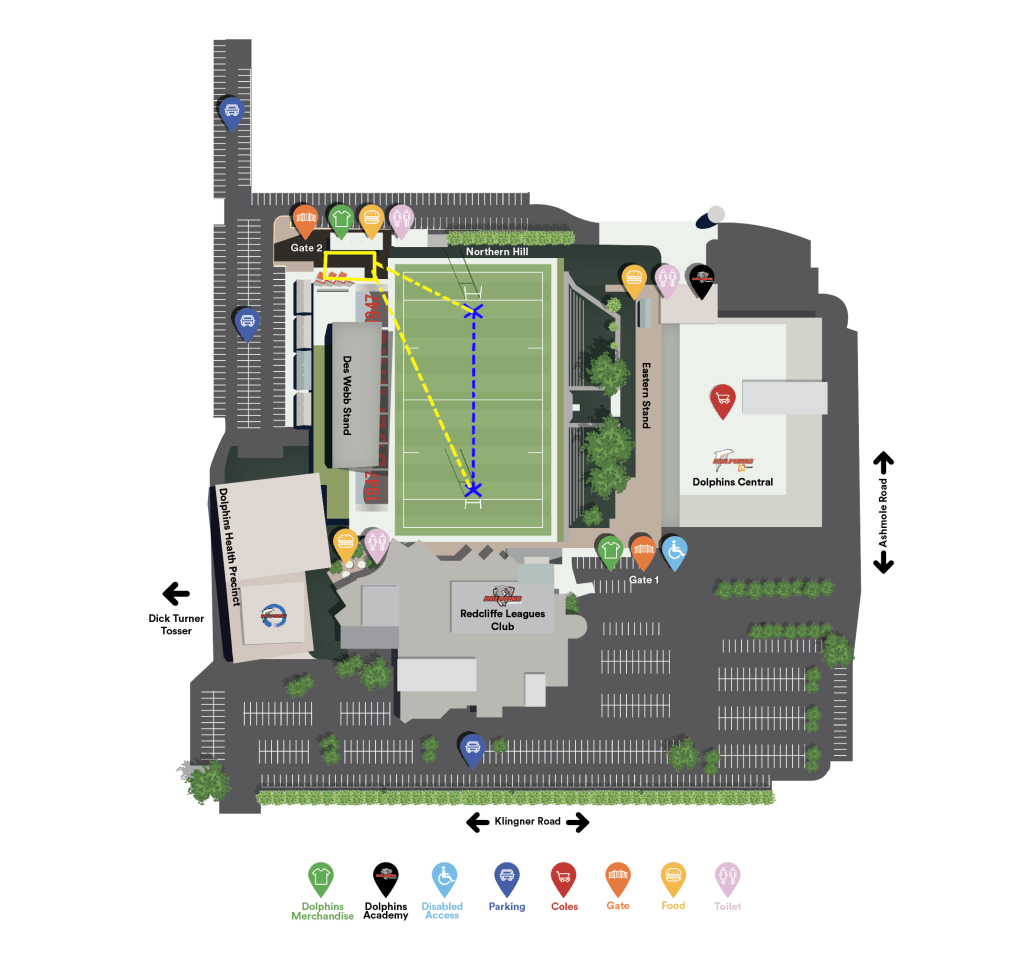

Where: Kayo stadium / Coles parking (entry through Gate 2)

1. Brief Demo Flight Description and Defined Goals

This demo flight aims to showcase the first successful lift-off, controlled flight, and safe landing of our hydrogen airship.

Demo primary goals:

- Demonstrate take-off with a 1kg payload.

- Achieve stable and controlled straight flight for 50m at 5m height.

- Execute a controlled landing.

- Utilize hydrogen gas as both a lifting agent and a power source via the installed hydrogen canister and fuel cell.

Demo secondary goals:

- Hovering at specific altitude for longer duration.

- Demonstration of precise turns or other maneuvers.

- Controlled ascent to a higher altitude with live telemetry.

- Speed test.

- Demonstrate effective ballast control.

Design Goals:

- Usage of vectoring thrusters.

- Demonstration of the central duct constructed from carbon fiber (CF) materials.

- Prove the stability of a dual-hull (biconvexial) design compared to a single-hull structure.

- Utilize Industry 4.0 manufacturing techniques including welding, gluing, and 3D printing.

- Demonstrate the utility of 360-degree gimbals for assistance during take-off, flight, and landing.

- Collect GPS readings

Key success criteria include achieving a smooth take-off, maintaining steady hover for a pre-determined duration, performing simple maneuvers, and executing a safe landing.

2. Prerequisites

- Environmental Conditions

- Weather: No wind or maximum light breeze (< 15km/h throughout the demo window). No rain prediction.

- Temperature: Ideal conditions within the safety range for both the airship material and hydrogen ( < 25C)

- Time: Early morning or late evening to avoid direct thermal lift and minimize wind.

- Wind direction: Inflatable balloon to have a visual indication on conditions

- Hardware & Materials

- Airship Parts: Complete inventory including envelope, propulsion system, gondola, and control surfaces.

- Batteries: Fully charged power packs for flight control and propulsion.

- Tools & Spares: Hand tools, spare parts, welder, razor-blade (emergency tether release).

- Adhesives: Superglue, Alumin tape, Red & Green tape, Gorilla tape.

- Safety Equipment: Fire extinguisher, first aid kit, safety goggles.

- Setup Materials: Sun cover for shade, ground protection sheets for assembly.

- Measuring tools: Anemometer, Multimeter.

- Hydrogen

- Permissions and People

- Area Access Permission: Documented permissions for the location.

- Test Commencement Approval: Obtain clearance for using hydrogen.

- Safety Officer: Designated individual responsible for monitoring safety.

- Engineers: Personnel to handle airship assembly, calibration, and troubleshooting.

- Documentation Team: Individuals responsible for capturing footage (time-lapse, ground-based photos, drone shots).

- PR and Engagement: Person to handle media and audience interaction.

- Catering: Food and beverage arrangements for the team and potential guests.

- Entertainment: Optional, for invited guests during waiting times.

3. Airship Assembly Instructions

- Step-by-Step Guide

- Secure area: “No entry” tape and bollards

- Distribute hi-visibility vests as per team contact information table

- Unpack and Inspect Components: Ensure all parts are present and intact.

- Ground Sheet Setup: Lay out protective sheets to prevent contamination.

- Main structure assembly:

- Insert main duct tubes (back first)

- Power cables lead in through sleeves

- Insert main traverse tubes

- Gondola and Propulsion Attachment: Secure the gondola to the envelope with safety checks.

- Battery Connection and Electronics Check: Ensure all electronics are functional and calibrated.

- Inflate “wind direction balloon”

- Envelope Inflation:

- Check that maintenance openings are taped

- Check that release vents are closed and sealed

- Check that wedge clamps are locked

- Fill ballast tanks

- Payload installed and secured

- Check that filling hose clips are available and ready to use

- Final Pre-Flight Inspection: Full system check including weight balancing.

4. Detailed Demo Schedule

Go/No go decision by 6pm day before.

- 05:00 AM: Team Arrival and Setup.

- 05:20 AM: Safety Briefing and Final Equipment Check.

- 05:40 AM: Begin Airship Assembly.

- 07:30 AM: System Tests (Electronics, Propulsion, Stability).

- 08:00 AM: Wind conditions check and Start position designation

- 08:00 AM: Camera’s rolling

- 08:00 AM: Demo Flight Commences

- 08:15 AM: Controlled Hover and Manoeuvring Demonstration

- 08:30 AM: Landing Procedure and Deflation

- 09:00 AM: Post-Demo Review and Debrief

5. Checklist

- Safety Protocols: All personnel briefed and equipped.

- Flight Conditions: Weather verification.

- Hardware: Final check on airship components and tools.

- Media: Ensure all cameras and recording devices are operational.

6. Safety Procedures and Potential Disaster & Malfunction Scenarios

Team and Audience Safety Briefing

- Security Officer Introduction: The Security Officer will introduce themselves and explain their role in ensuring everyone’s safety.

- Disaster Scenarios Overview: A quick run-through of potential disaster scenarios and the appropriate actions to be taken.

- First Aid Introduction: The First Aid Officer will be introduced, and the location of the first aid kit will be announced.

7. Site Preparation

- No-Access Area Designation: A restricted area will be designated using bollards and CAUTION tape during site preparation. Only authorized personnel are allowed to enter this area.

8. Potential Disaster Scenarios

- Envelope Rip: If an envelope rip occurs, damage will be assessed:

- If the rip occurs before hydrogen fill and can be welded on site with by a soldering pipe and Alumin tape, proceed with repairs.

- If the damage cannot be repaired before hydrogen fill, the session will be cancelled.

- After hydrogen filling, only Alumin tape should be used for repairs to prevent any fire hazard.

- Hydrogen Fire: All audience members should maintain a minimum safe distance of 5 meters at all times. In the event of a fire, this distance should be extended to 10 meters.

- Hydrogen burns quickly upwards with minimal risk of burns due to its low energy density.

- No fire extinguishing should be attempted to avoid further complications. Hydrogen will be released into the air via upper release valves immediately after the demo flight.

- All materials to come in contact with Hydrogen (silicone inflation tube, ABS nozzle / valve, Tritex-X material) are static-resistant not to spark.

- Li-Ion Batteries on Fire: A powder-based extinguisher will be available on site for use by the designated safety officer in case of a fire.

- Batteries will be kept in a safety bag as long as possible and installed just before the flight. They will also be removed as the first action after landing.

- In-Flight Failure: No personnel should be directly beneath the airship during flight to avoid the risk of injury from falling parts or debris.

- Airship Out of Control: The airship will be tethered at all times using a minimum of 4 tethers attached to each gimbal.

- All tethers will be secured and monitored by assembly technicians. Under no circumstances should personnel be located directly under the airship during flight.

- The average flight height will be 5 meters, with a maximum height of 10 meters.

- Tethers will be marked at 5 meters (green), 8 meters (yellow), and 10 meters (red) to provide a clear visual guide to the current height and safety status.

- Drone collision:

9. Malfunction Scenarios

- Intake Engine Not Working or Not Generating Thrust

- Scenario: Any intake engine fails to generate thrust.

- Action: The failure will be investigated by:

- Checking power cable connections.

- Checking the signal cable to ESC connection.

- Assessing ESC health (2 ESC spares are available).

- Outcome: If the issue cannot be fixed on-site, the test will be considered a failure.

- Gimbals Not Actuating or Engines Not Working with Proper Thrust Direction

- Scenario: Any gimbal or engine fails to actuate or generate thrust.

- Action: The failure will be investigated by:

- Checking power cable connections.

- Checking the signal cable to ESC connection.

- Assessing ESC health (2 ESC spares are available).

- Assessing servo health (5 spare servos available).

- Outcome: The test will be considered a failure if more than one gimbal or engine cannot be fixed on-site. A minimum of 3 gimbals in working condition is acceptable.

- Vectoring Thrusters Not Actuating

- Scenario: Any vectoring thruster fails to actuate.

- Action: The failure will be investigated by:

- Checking power cable connections.

- Checking signal cables.

- Assessing servo health (5 spare servos available).

- Outcome: The test can proceed even if both vectoring thrusters fail, as they are not mandatory for the success of this demo.

- Battery Pack Voltage Levels (6V for Servos, 9V for Arduino and RC Receiver, 25V for Engines)

- Scenario: Any battery pack shows insufficient voltage.

- Action: Replace the battery pack (spares are available for all types).

- Outcome: For the 25V battery pack, as two are installed but only one is needed, the test can proceed if at least one is full.

- RC Controller Battery Voltage

- Scenario: RC controller battery shows insufficient voltage.

- Action: Replace the batteries (4x AA battery replacements are available).

- Ballast Tanks Failure

- Scenario: Ballast tank cannot be filled or is unable to release water.

- Action:

- If the tank lacks water, refill.

- If the release mechanism fails, check power control and remote connections.

- Outcome: Ensure that at least 3 ballast tanks are working correctly. If fewer than 3 are operational, the test will be scrapped.

- Drone Collision

- Scenario: One or more drones used for aerial footage experience a collision — either with each other, the airship, or ground crew.

- Preventive Instructions to Drone Operators:

- Maintain a minimum horizontal distance of 10 meters from the airship at all times.

- Maintain altitude well above the airship’s flight ceiling of 10 meters, ideally operating above 15 meters for overhead footage.

- Under no circumstances should a drone descend below the airship or attempt close tracking of the envelope or gondola.

- Do not attempt 360-degree or orbit shots at close range during active flight unless coordinated in advance with the flight controller.

- Each drone operator must confirm their return-to-home settings are configured and tested.

- Only one drone with collision avoidance is permitted to operate below 15m, and only for stationary hovering.

- Action in Case of Collision:

- If a drone collides with another drone, operators should immediately return all active drones to base and assess for damage before resuming any flights.

- If a drone collides with the airship, the flight controller is to be notified immediately. The airship is to be stabilized, visually inspected (especially envelope and propulsion systems), and the flight paused or aborted depending on the impact location and severity.

- If a drone crashes near personnel, the site safety officer will secure the area, assess injuries if any, and ground all drones pending a safety review.

- Outcome:

- Any drone incident that results in damage to the airship envelope, propulsion, or flight control surfaces will trigger a full test abort unless immediate, safe repair is possible.

- Continued drone filming will only resume after verbal clearance from the flight controller and safety officer.

Annex A – Team

Team Contact Information Table

| # | Name | Role Assigned | Contact Information | Notified/Confirmed | Team |

|---|---|---|---|---|---|

| 1 | Jan Bilek | Lead Engineer | j****k@h2use.com | Y/Y | GREEN |

| 2 | Sebastian Bilek | Flight Controller | s****k@eftlab.com.au | Y/Y | GREEN |

| 3 | Mick Cullen | PR and Media Relations | m**k@cullent.net.au | Y/Y | SILVER |

| 4 | Simon Steffen | PR and Media Relations | s****i@gmail.com | Y/Y | SILVER |

| 5 | Kristian Nemeth | Assembly Technician | k****6@gmail.com | Y/Y | GREEN |

| 6 | Serge Testa | Assembly Technician | a****c@me.com | Y/Y | GREEN |

| 7 | Adam Galvin | Assembly Technician | N/A | Y/Y | GREEN |

| 8 | Christopher Drake | Documentation Team (FPV Drone operator) | c****e@cryptophoto.com | Y/Y | SILVER |

| 9 | Lumir Bodlak | Assembly Technician | l****k@gmail.com | Y/Y | GREEN |

| 10 | Vilem Cerny | Gas Cylinders Operator | k****i@gmail.com | Y/Y | RED |

| 11 | Martin Kosik | Documentation Team Lead | m****l@gmail.com | Y/Y | SILVER |

| 12 | Jakub Kosik | Documentation Team (Drone Operator) | o****m@gmail.com | Y/Y | SILVER |

| 13 | HOBR-girls | Catering & Logistics | N/A | Y/Y | N/A |

| 14 | Robert Mataic | Security Officer | TBA | Y/Y | RED |

| 15 | Paul Johannson | First Aid | TBA | Y/Y | RED |

| 16 | Damien Foy | Security Officer | TBA | Y/Y | RED |

| 17 | Channon | Security Officer | TBA | Y/Y | RED |

| 18 | Branislav Kusy | Assembly Technician | TBA | Y/Y | GREEN |

Colour code:

- RED – Security & Safety

- GREEN – Engineering

- SILVER – Media and documentation

Annex B – Guests

| # | Name | Affiliation / Role | Notified/Confirmed |

| 2 | Branislav Kusy | CSIRO | Y/Y |

| 26 | Andy & Jane | Guest | Y/Y |

| 29 | Anfried | Guest | Y/Y |

| 32 | Jimmy & Maruska | Guest | Y/Y |

| 33 | Guest | Y/Y | |

| 34 | Michal & | Guest | Y/Y |

| 38 | Greg & Liz Williams | Guest | Y/Y |

| 40 | Mirek | Guest | Y/Y |

| Y/[N/Y] | |||

| 45 | EJ Bermingham | Guest | Y/Y |

| 47 | Y | ||

| 48 | Nick Hofstetter | Guest | Y/Y |

| Y | |||

Annex C – Pre-flight check list

| # | Checklist Item | Status / Value |

| 1 | Port intake engine working and generating thrust | [ ] |

| 2 | Starboard intake engine working and generating thrust | [ ] |

| 3 | Port-bow gimbal actuating and engine working, propeller generating thrust in the appropriate direction | [ ] |

| 4 | Starboard-bow gimbal actuating and engine working, propeller generating thrust in the appropriate direction | [ ] |

| 5 | Port-stern gimbal actuating and engine working, propeller generating thrust in the appropriate direction | [ ] |

| 6 | Starboard-stern gimbal actuating and engine working, propeller generating thrust in the appropriate direction | [ ] |

| 7 | Port-stern vectoring thruster actuating | [ ] |

| 8 | Starboard-stern vectoring thruster actuating | [ ] |

| 9 | Record 6V battery (servos, solenoids) pack voltage signaling batteries full | [ ] / Value: ____ V |

| 10 | Record 9V battery (Arduino and RC receiver) pack voltage signaling batteries full | [ ] / Value: ____ V |

| 11 | Record 25V battery (engines) pack voltage signaling batteries full | [ ] / Value: ____ V |

| 12 | RC controller battery signaling batteries full | [ ] |

| 13 | Port-bow ballast tank full and able to release | [ ] |

| 14 | Starboard-bow ballast tank full and able to release | [ ] |

| 15 | Port-stern ballast tank full and able to release | [ ] |

| 16 | Starboard-stern ballast tank full and able to release | [ ] |

| 17a | Port-bow lead tether attached | [ ] |

| 17b | Starboard-bow lead tether attached | [ ] |

| 17c | Port-stern lead tether attached | [ ] |

| 17d | Starboard-stern lead tether attached | [ ] |

| 17e | Central lead tether attached | [] |

| 21 | Port envelope wedge straps tight | [ ] |

| 22 | Starboard envelope wedge straps tight | [ ] |

| 23 | Port envelope gas release valve closed | [ ] |

| 24 | Starboard envelope gas release valve closed | [ ] |

| 25 | Inflation vent(s) closed | [ ] |

Annex D – TODO

| Who | What |

| Vilem | hydrogen soldering tools bollards flood lights |

| Adam / Lumir | gazebo flood lights |

| Kristian | cloth flood lights anchor leads camping table |

| Richard | soldering tools multi-meter flood lights |

| HOBR girls | coffee drinkable water cups |

| Jan | speaker(s) reflection vests inflatable baloon |

| Seb | working and charged drone |

Annex E – Weather forecast

19/5/25 – Rain chance 18%, wind 7 km/h NNE

20/5/25 – Rain chance 0%, wind 5 km/h SW

21/5/25 – Rain chance 0%, wind 5 km/h W

22/5/25 – Rain chance 0%, wind 5 km/h SW