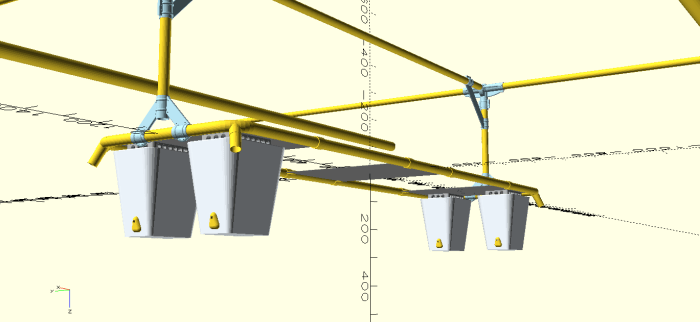

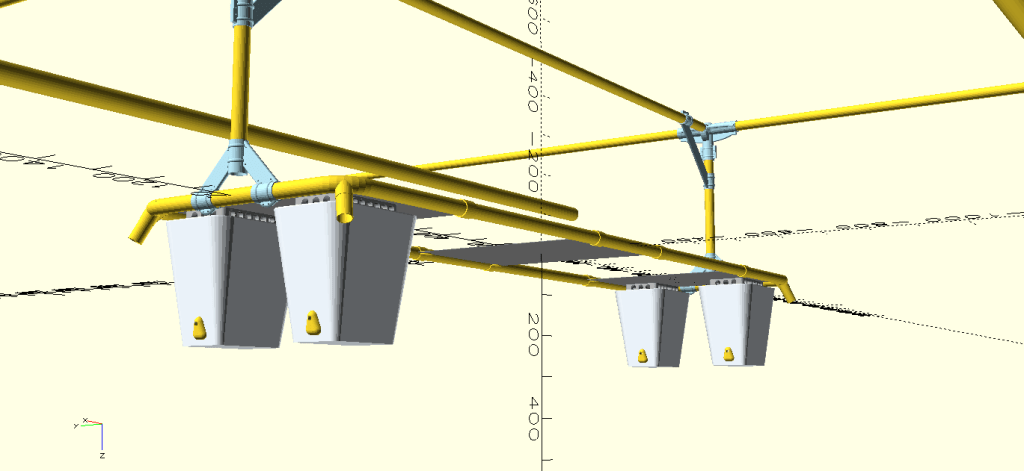

One challenge in the development of our hydrogen airship was managing excess lift—around 10kg too much. This opened an opportunity to implement a controllable ballast system that could be actuated remotely in-flight. We designed and tested a four-tank solution, with each water ballast tank located in a corner of the gondola.

Each tank system consists of a plastic container mounted to the gondola platform, featuring a normally-closed solenoid air valve at the top and an always-open water release valve at the bottom. Water release is only possible when air is let in through the solenoid, effectively controlling when and where weight is shed.

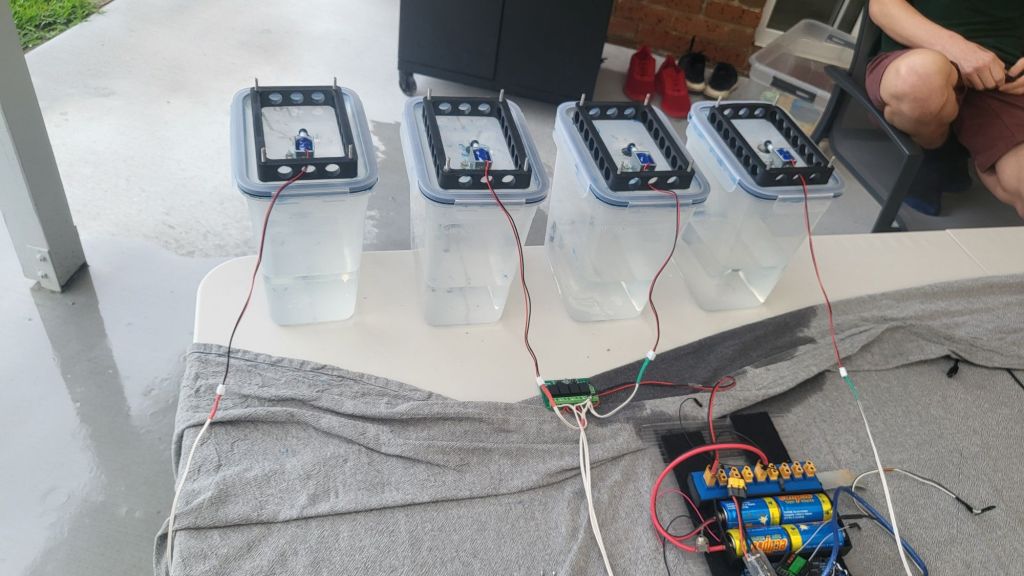

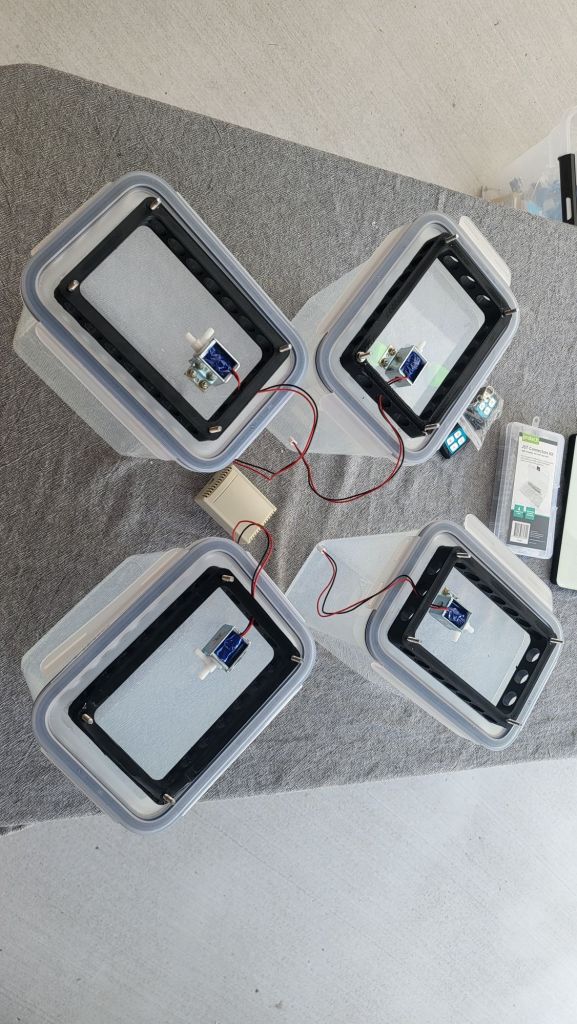

The entire setup was prototyped using:

- Mini Electric Solenoid Valves (DC 6V/12V/24V) from Aliexpress

- 365+ Food containers (4.2L, Ikea)

- A 443MHz 4-channel wireless RF remote controller from eBay

- 3D printed components using OpenSCAD modules

<ShortCuts.scad>and<blimp_parts.scad>

Following goals were pursued:

- Design a simple, lightweight and remotely-actuated ballast mechanism – done

- Assemble and test single unit operation – done

- Integrate ballast system into gondola corners – done

- Perform full-weight “airborne” test with simulated load – done

- Validate structural integrity under full ballast + battery weight – done

Final ballast system ready for integration:

Ballast system in action:

Development gallery

Posts being added as project develops: