Last week, Chris Drake and I had the incredible opportunity to visit One Composites, a cutting-edge composite manufacturing company based in Coolum Beach, Queensland. We were welcomed by none other than the company’s owner, David Biggar, who personally guided us through their state-of-the-art facility.

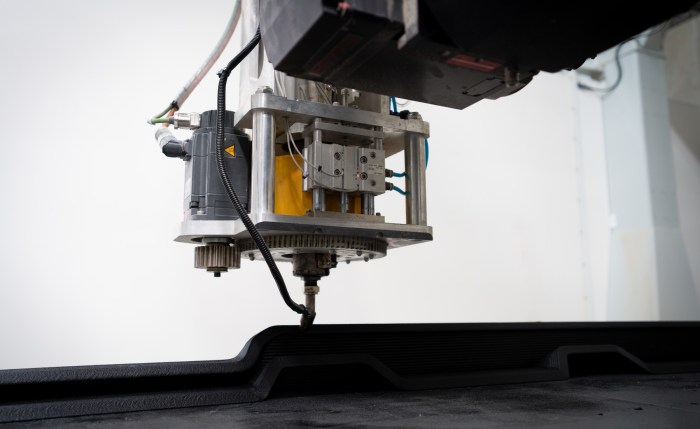

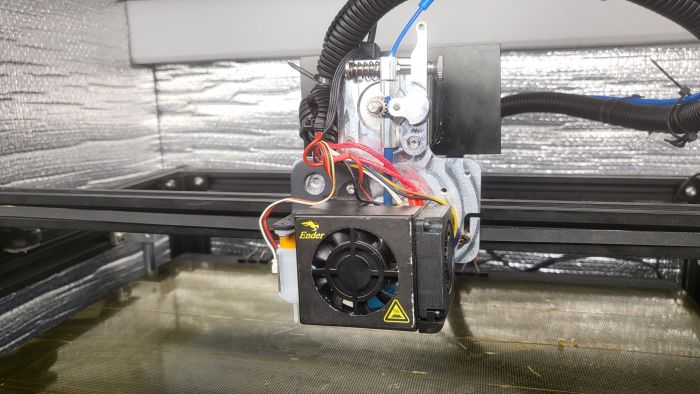

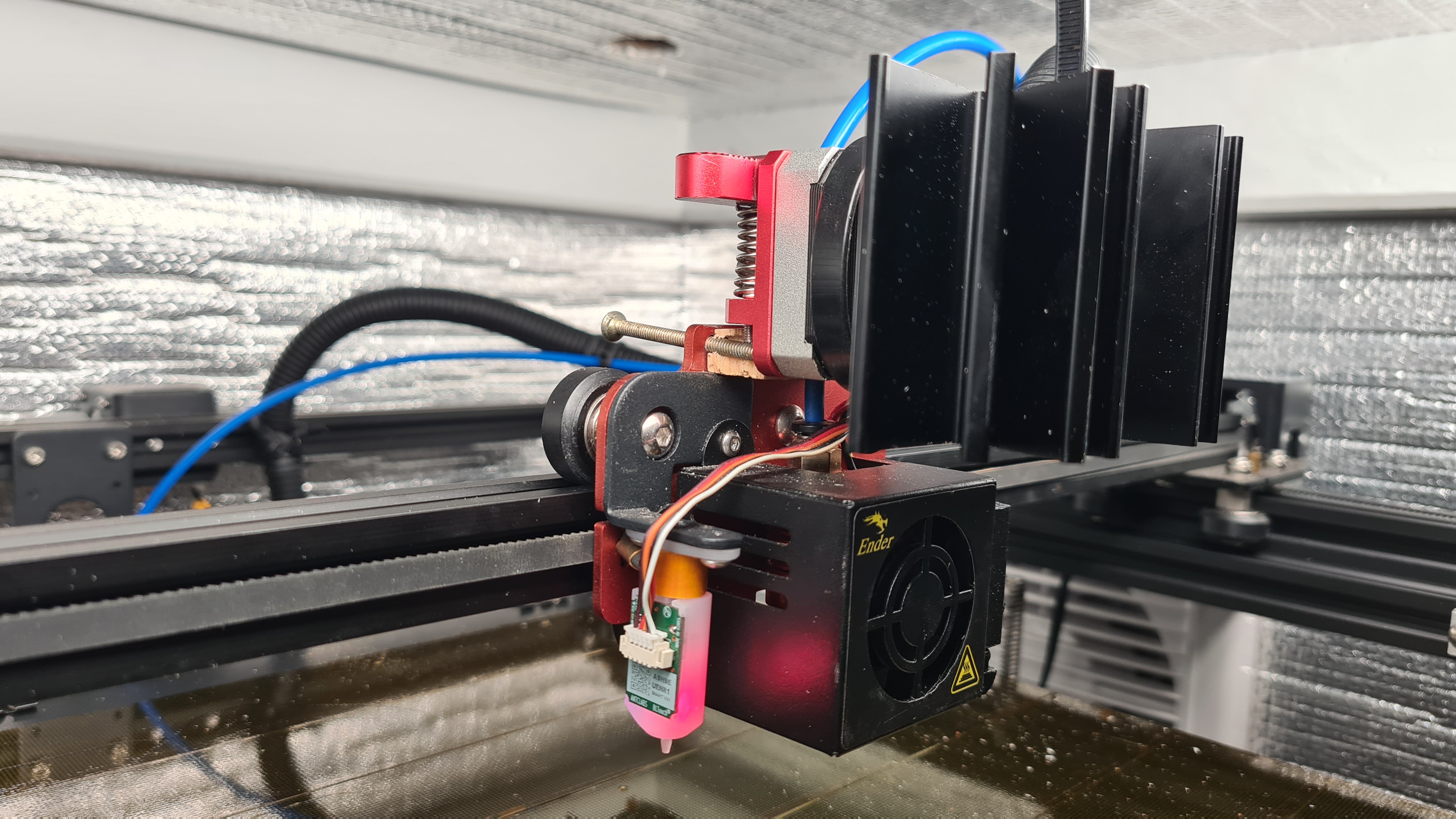

One of the standout moments of the visit was witnessing the largest 3D printer in the Southern Hemisphere in action – measuring approximately 15 meters in length and 6 meters in width. This beast can print up to 2.5 tons of material within 24 hours, using a carbon fiber-infused filament with density of up to 25%. The potential applications of such technology are vast, from rapid tooling and prototyping to full-scale production of high-strength, lightweight components.

David Biggar’s passion for composite materials was evident as he walked us through the facility. One Composites specializes in everything from fiberglass and carbon fiber production to large-format printing and 5-axis milling. Their ability to produce high-detailed components quickly and efficiently makes them a key player in Australian composites industry.

For our hydrogen airship project – the combination of lightweight yet strong materials is critical for efficient flight. The advanced manufacturing techniques we saw at One Composites open up avenue for our Phase II project. Discussions with David also hinted at future collaboration opportunities, as we explore the integration of composite materials in airship structures.

During our visit, I took several pictures (with Dave’s permission) and one video to document the experience – enjoy!