Since the beginning of our carbon fibre (CF) tube manufacturing journey, one question has lingered in my mind—how strong are these tubes, really? We knew they would be lightweight and durable, but with their role in critical load-bearing parts like our EDF (Electric Ducted Fan) intakes and 3D thruster mounts, we had to be sure. Initial tests and assemblies exposed the reality: some of the early designs couldn’t handle the stress. A few unfortunate failures under load made it clear we needed a stronger solution.

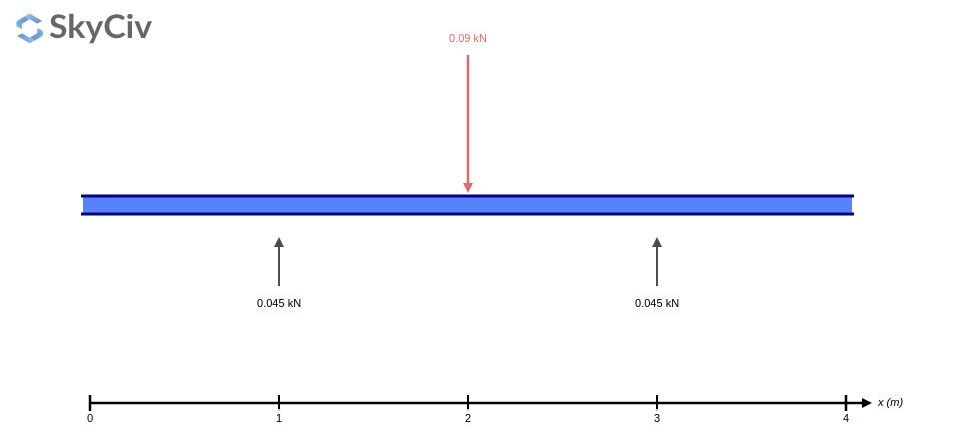

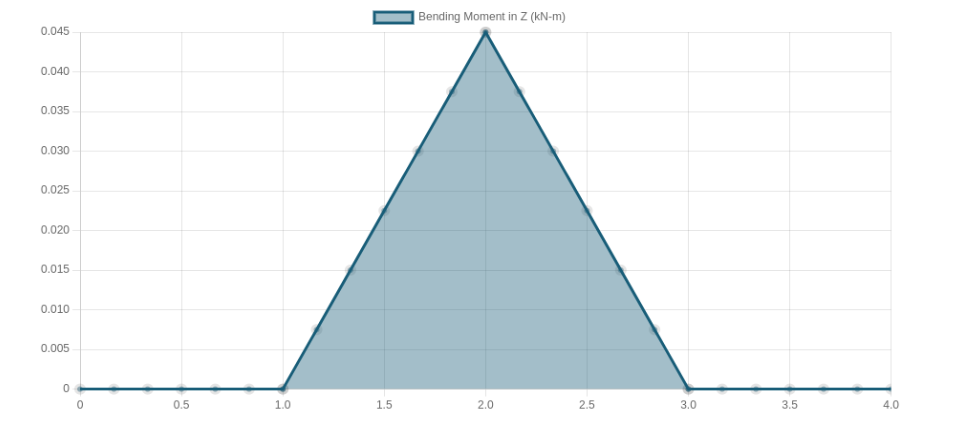

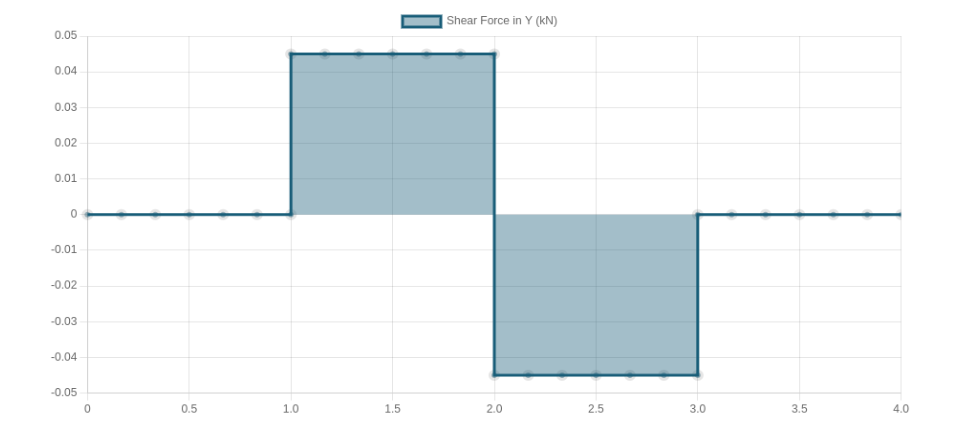

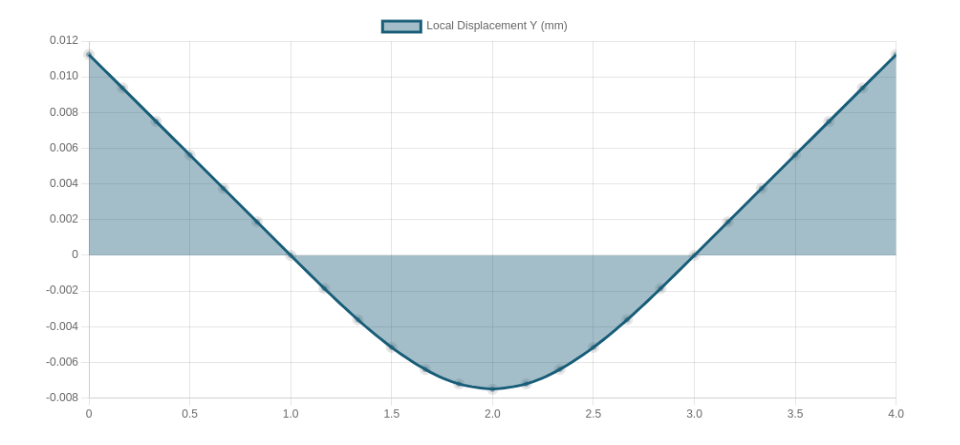

Actually, main focus has been on those traverse tubes connecting main tubes with gondola and so bearing the main load of a whole airship. I ran SkyCiv to demonstrate our situation (probably used this one before):

Reactions at Supports

Bending moment

Shear Force Diagram

Deflection

This is where Serge stepped up and over the past few weeks rethinking the reinforcement of our most critical CF tubes. Serge’s solution? Using leftover CF tape and polyester resin, he reinforced the high-stress zones. The result? A beautifully layered enhancement that practically doubled the strength of the traverse tubes. Enjoy watching Serge in action!

We weren’t going to stop just there. These reinforced tubes were put to the test—and passed with flying colours. They now comfortably support over 10kg of load, simulating real operational stress, including a suspended weight (like a 10kg water bucket) at the center span.

The tests didn’t just prove the design—they validated Serge’s craftsmanship and wisdom. It’s been an absolute privilege to learn from him and watch him bring decades of know-how into this project. Thank you Serge!

Ten Serž je dobrej

LikeLike